Application products/industries: Aquatic product processing, slaughter processing, vegetable distribution and preservation, supermarket freshness, aquatic product market preservation, marine fishery etc.

Integrated Turnkey Project Solution

Complete Set of "Block Ice Factory"

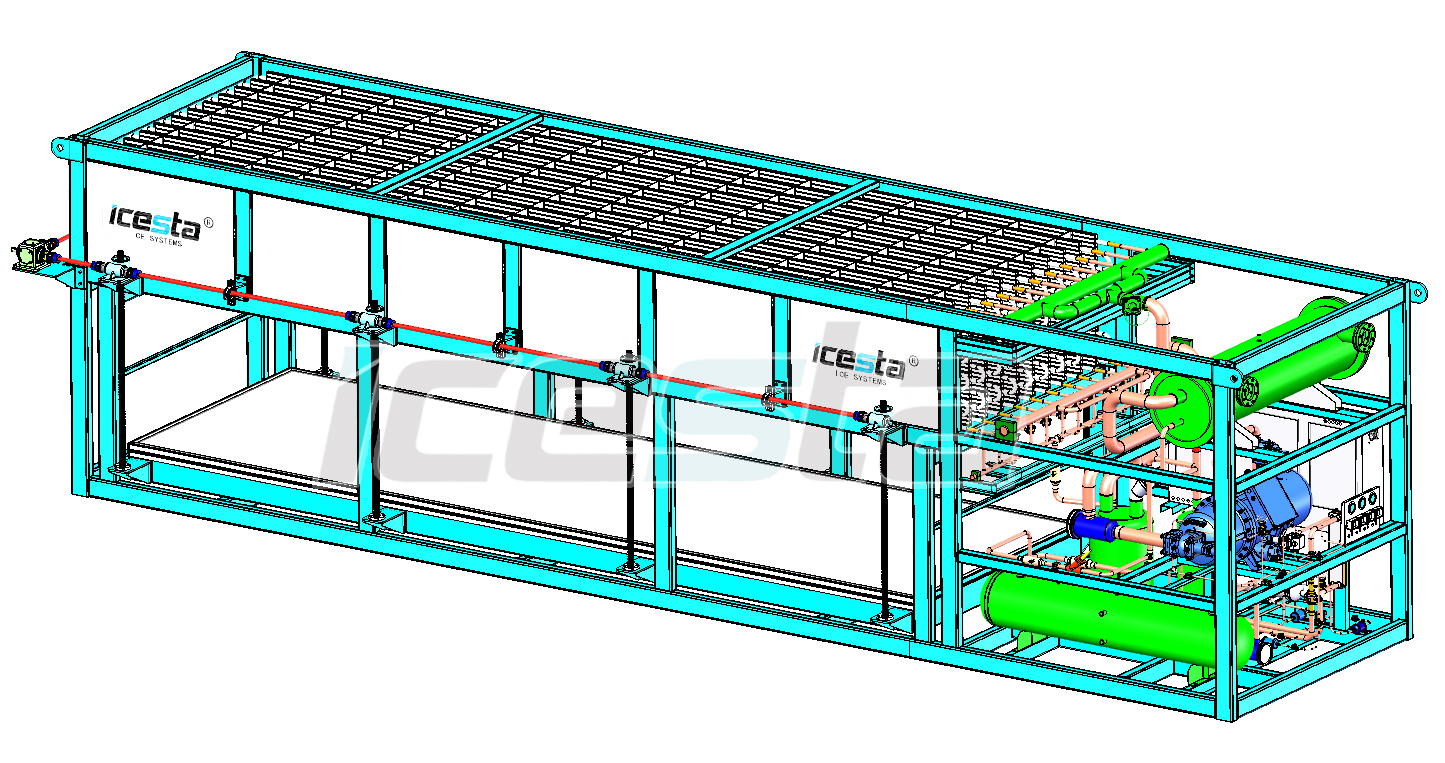

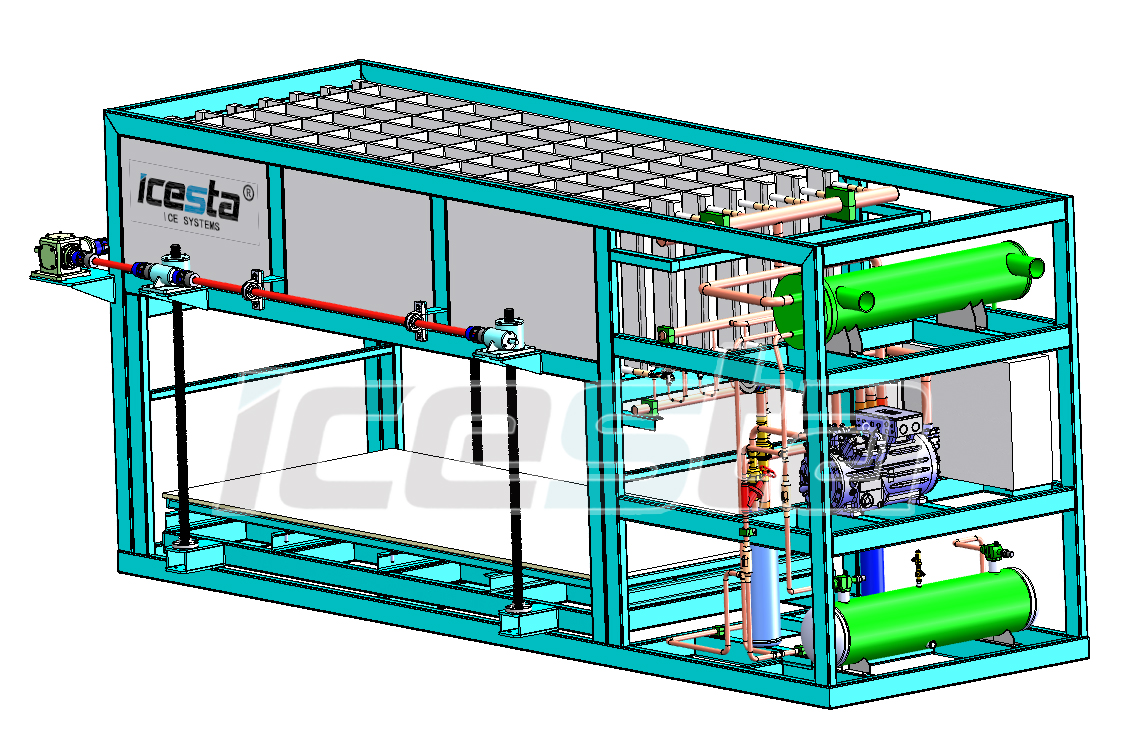

--------------All-In-One Automated Modular Block Ice system

include Ice making & Storing & Delivery System

Over the past 15 years, ICESTA's strong R&D and engineering teams have continuously provided customers with first-class customized ice solutions and complete-set Turnkey projects.

I. Industry Application

ICESTA All-In-One Automated Modular Block Ice system consists of Ice making & Storing & Delivery System involves:

◪ Aquatic product processing

◪Slaughter processing

◪Vegetable distribution and preservation

◪Supermarket freshness

◪Aquatic product market preservation

◪Marine fishery

I.Before Solution Designing

Communication before scheme design:

ICESTA's Large Ice Solution has a very rigorous design process and PMP Project Management Procedure (please refer to the link menu “Procedure Flowchart & PMP System”). The following important communications must be made before the design of the scheme:

1. Application products/industries: Aquatic product processing, slaughter processing, vegetable distribution and preservation, supermarket freshness, aquatic product market preservation, marine fishery etc.

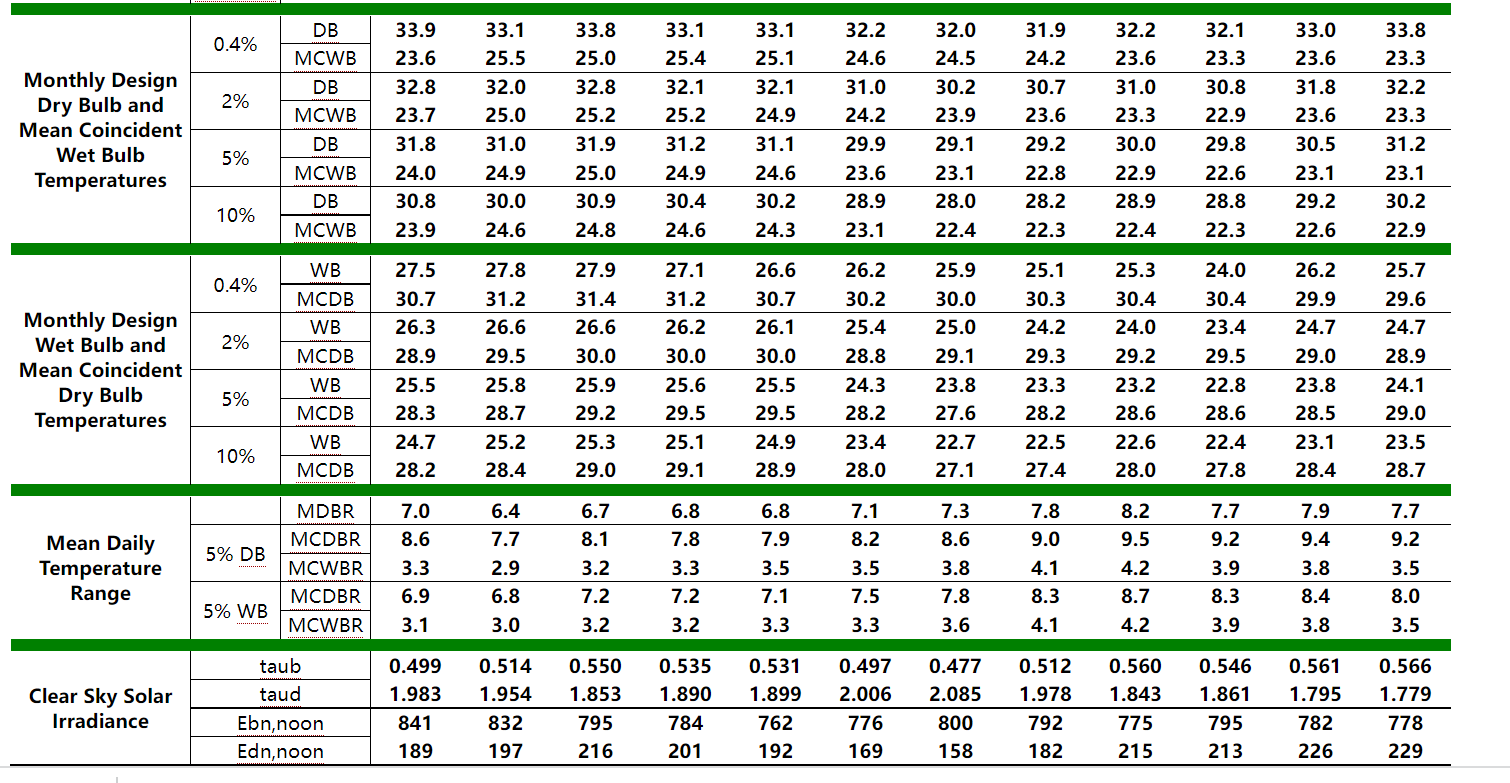

2. On-site environment: use area (national area, climate), workshop size, installation environment (open air, outdoor, indoor), water quality (salinity, etc.), water source (abundant or scarce water source, groundwater, or tap water, etc. ), ambient temperature (maximum air temperature, minimum air temperature), air salinity, water temperature, wet bulb temperature, etc., use the distance between the freezing point and the ice storage room or ice using place

For example, the web bulb temperature effect the technical selection of evaporative condenser

3. Use requirements: 24-hour ice production (1T, 2T , 3T, 5T ...) , ice weights (10kgs, 25kgs, 50kgs ...) etc.

4. Technical requirements: cooling method (air cooling, water cooling, evaporative cooling), voltage requirements (pay special attention to special voltages: 380V 3P 50HZ, 220V 3P 60HZ, 440V 3P 60HZ, 480V 3P 60HZ, 380V 3P 60HZ), materials, compressors and other important components brands etc., need to be analyzed for specific products.

II. Solution Design & Parts Description

After the customer’s demand confirmed,our technical team recommend the most suitable snow making system, design the scheme and program, then ICESTA sends the detailed proposal.

* Example ----

4 sets 30tons/24hrs Block ice machine with 50kgs ice

1. 4 sets 30tons/24hrs direct cooling block ice machine

The evaporator is made of aluminum alloy, and the refrigerant evaporates directly in the evaporator to make ice without any other heat transfer carrier (such as salt water).

Advantage

a. Energy conservation and environmental protection.

The refrigerant directly evaporates heat exchange to make ice, the ice making efficiency is improved, making per ton ice could save 20% electricity , and there is no salt water as the heat transfer medium, the ice made is also more cleaner.

b. Operation is simple, cost saving, small area.

Automatic water supply, ice making and deicing. The whole process of ice making and deicing does not require manual intervention. No other equipment needed, such as ice melting pool, ice inversion rack, water supply device and line crane. Smaller area needed and greatly reduces the labor intensity of workers and saves labor costs.

c. Stable and durable, low maintenance cost.

Aluminum frozen plate used in aluminum alloy evaporator is extruded once, with high strength, no deformation, no rust, and no need to be replaced in service life. And without salt water corrosion, parts will not be damaged by corrosion replacement (such as ice mold, evaporator, water pump), low maintenance costs.

d. Fully automatic ice pushing device.

No need stuff to pick up the ice under the ice evaporator. Efficiently and safe.

e. Water cooled condenser.

Air cooled condenser, evaproative cooled condenser as options

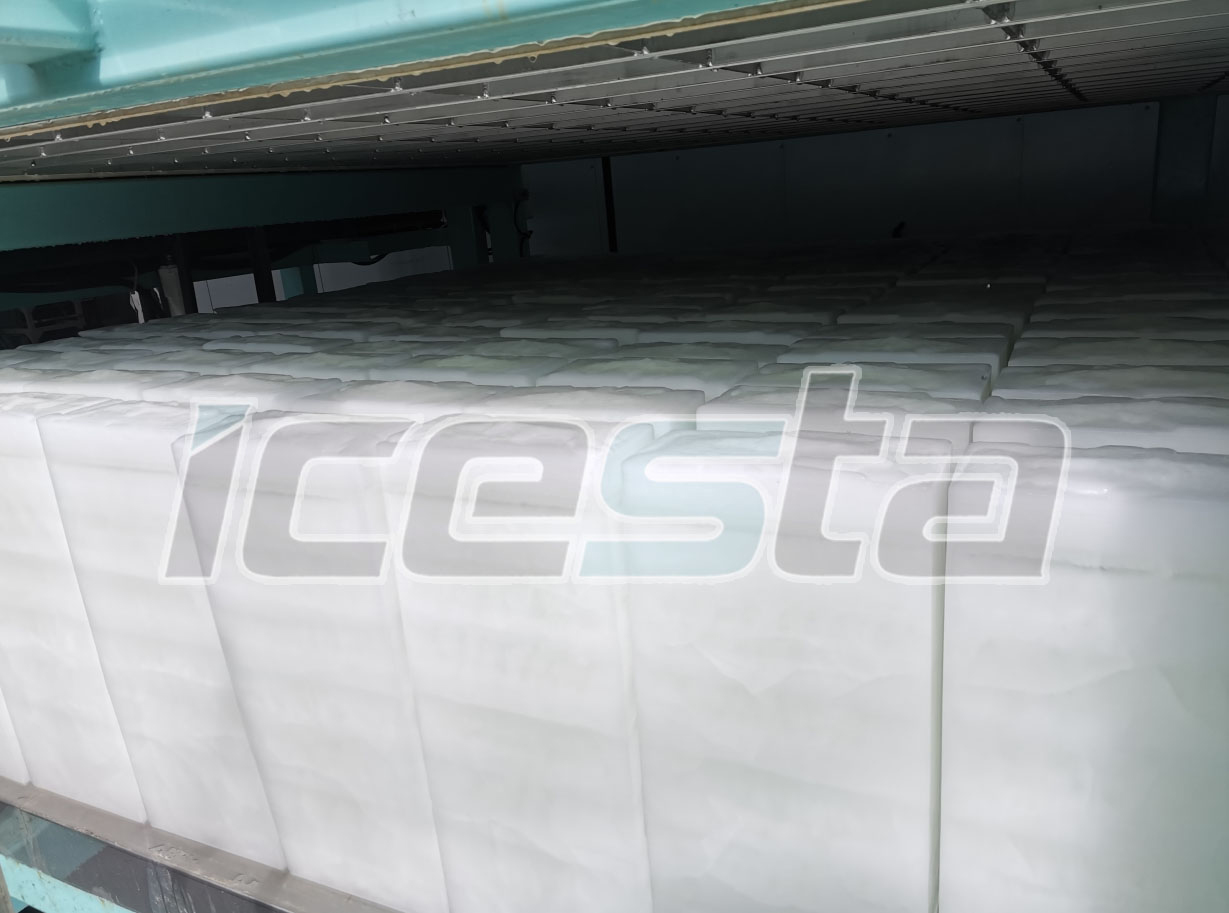

f. 50kgs per piece of ice

Block ice standard specification :10 kg 、25kg 、50kg 、100kg .100kg ice is too big and heavy, not easy to freeze, For large ice capacity machine, we recommend 50kg.

g. Ice conveyor for delivering ice to the ice storage room or ice crusher etc.

Customized length and height

h. Ice crusher ----One ice machine, two types of ice shape

III. Project references:

1. 2X 24tons water cooled block ice machine with 50kgs ice (Philippines)

2. 25tons water cooled block ice machine with 25kgs ice (Guatemala)

3. Taiwan ICE FACTORY