Integrated and Customized Turnkey Project Solution

Complete Set of "Artificial Ski Resort Solutions "

------Snow making system

include snow making & Storing & Delivery System

Over the past 15 years, ICESTA's strong R&D and engineering teams have continuously provided customers with first-class customized snow-making solutions and complete-set Turnkey projects.

I. Industry Application

ICESTA automatic snow making system consists of snow making & Storing & Delivery System involves:

* Outdoor Artificial Ski Resort

* Snow Turbing

* Indoor Snowhouse

*Atmosphere creating

II.Before Solution Designing

The Communication before Solution design,Very very important.

ICESTA has a very rigorous design process and PMP Project Management Procedure (please refer to the link menu “Procedure Flowchart & PMP System”). The following important communications must be made before the design of the scheme:

Application place : such as indoor, or outdoor, for skiing, turbing, atmosphere creating or just for viewing.

On-site environment:

* usage area (national area, countries, even cities),site size, installation environment (open air, outdoor, indoor),water source (abundant or scarce water source, groundwater, or tap water, seawater, etc. ),

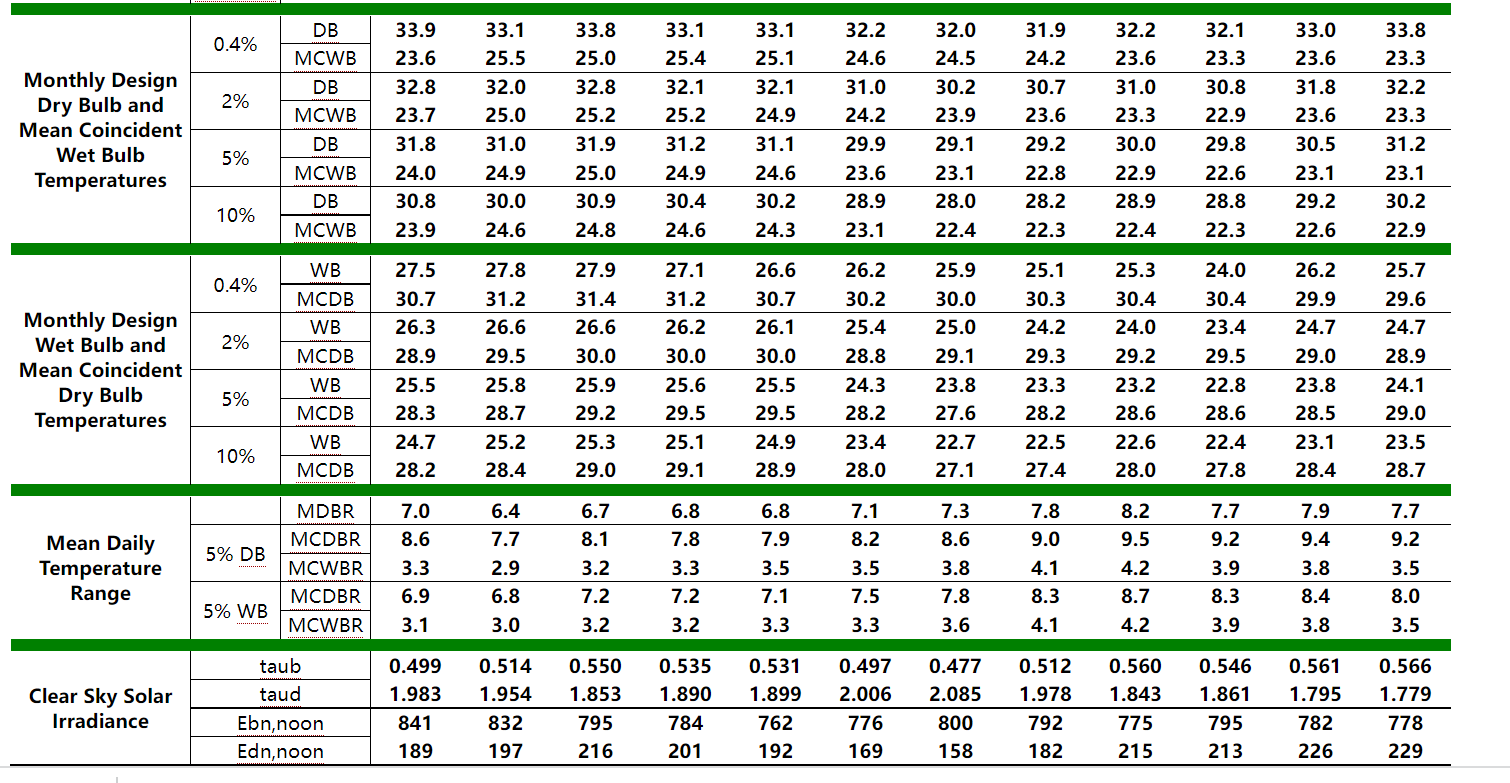

* ambient temperature (maximum& minimum temperature), air salinity, water inlet temperature, wet bulb temperature, etc., use the distance between the Ice using point and the ice building.

* Requirements for use: 24-hour snow production capacity, maximum snow storage capacity, maximum snow delivery capacity, daily snow usage time, snow using ice usage frequency, etc.

Technical requirements: cooling method (air cooling, water cooling, evaporative cooling), voltage requirements (available voltages: 380V 3P 50HZ, 220V 3P 60HZ, 440~480V 3P 60HZ, 380V 3P 60HZ), materials, compressors and other important components brands, whether to bring Generators, etc., need to be analyzed for specific products.

For example, the web bulb temperature effect the technical selection of evaporative condenser

III. Solution Design & Parts Description

ICESTA has different snow making systems according to customers’ different requiements and site conditions.

After the customer’s demand confirmed,our technical team recommend the most suitable snow making system, design the scheme and program, then ICESTA sends the detailed proposal.

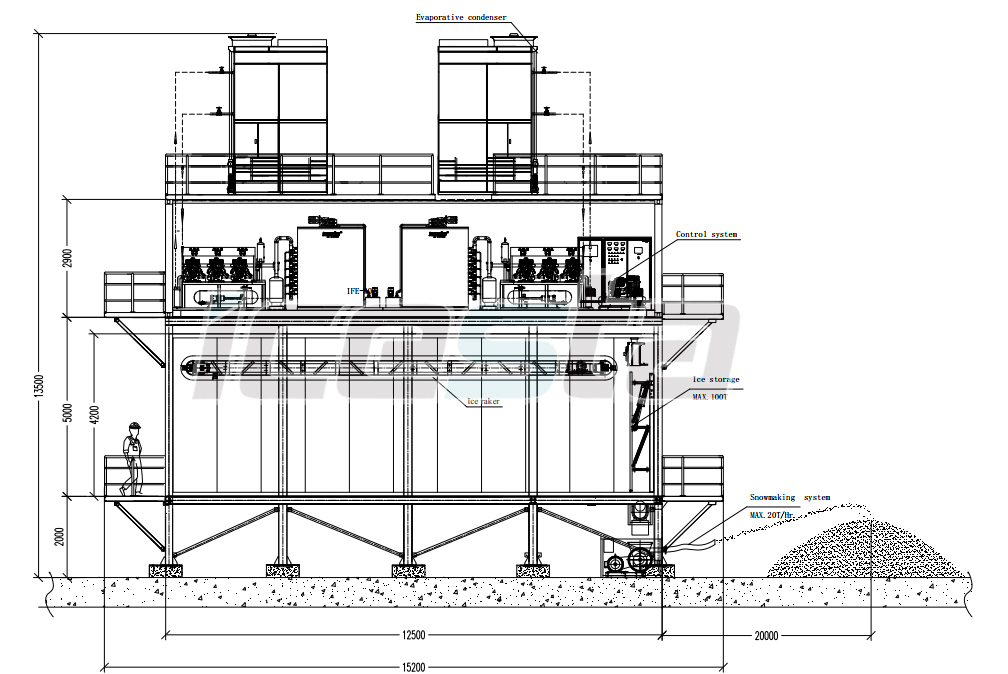

Example----TYPE A making snow from flake ice

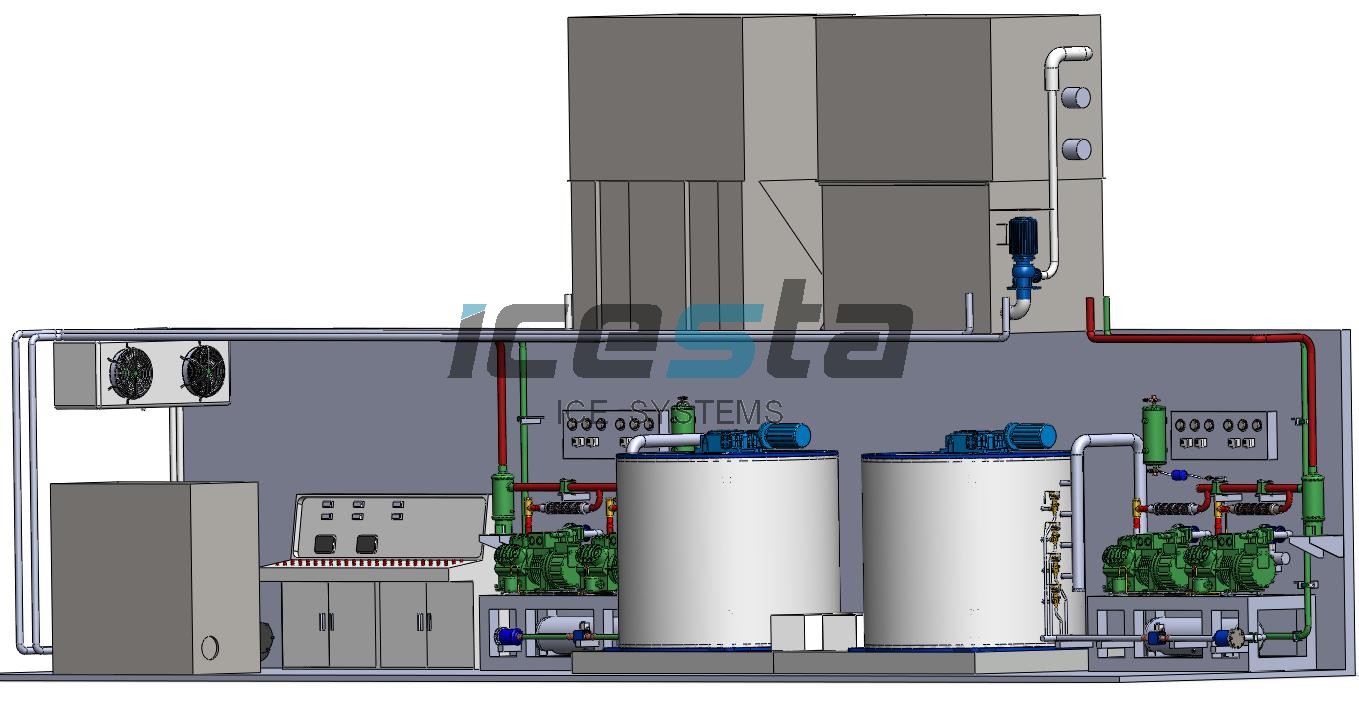

50tons/24hrs ice making system + 20tons snow storing & delivering bin + snow maker with blower

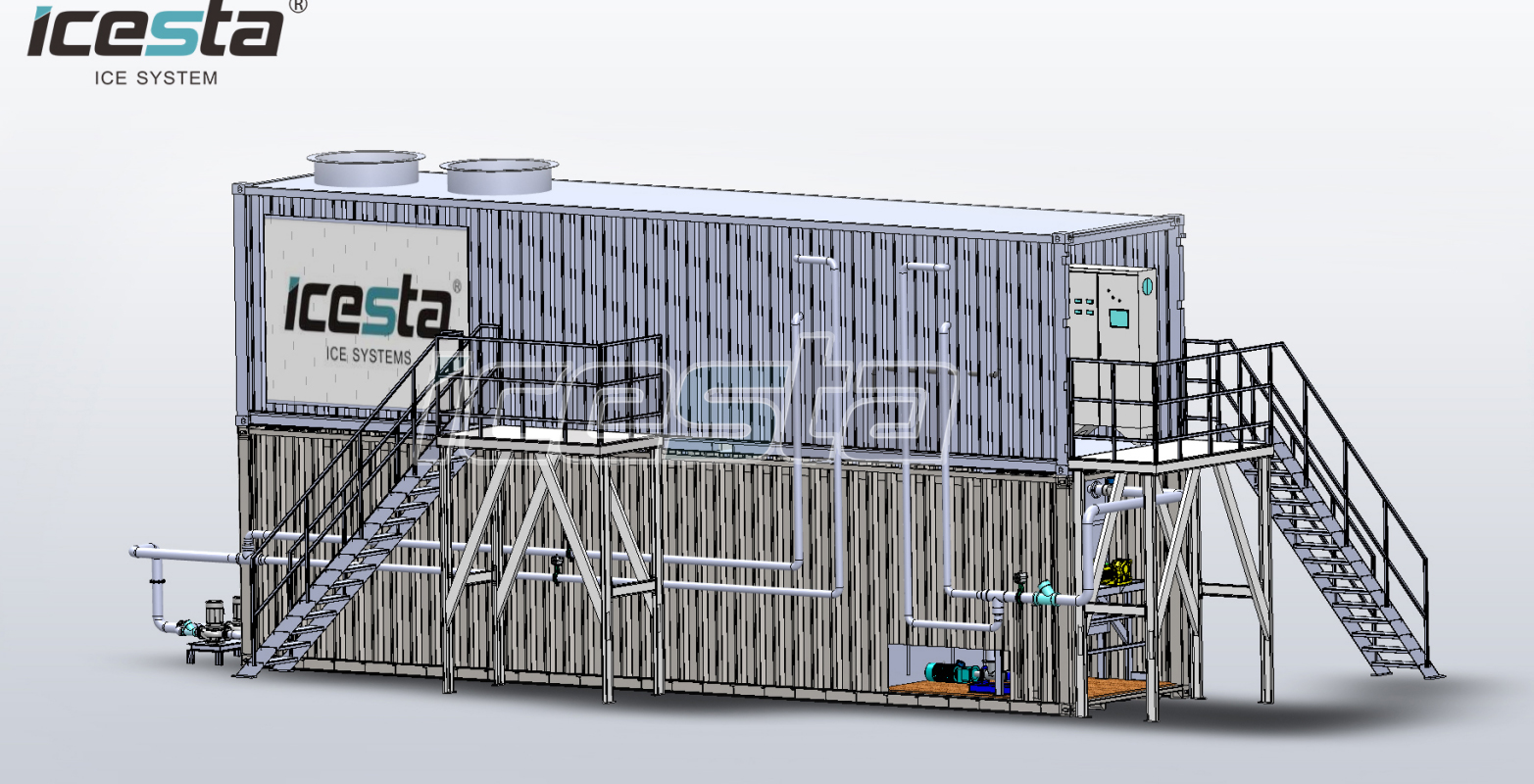

(Containerized)Flake ice machine

According to customer’s requirements, We supply

Standard Flake ice machine with container

Flake ice machine fitting in container (20FT, or 40HQ container). The ice machines are well fully pipe connected and tested fully before delivery from factory which give the user’s most convenience at site.

2*25tons per day evaporating cooling flake ice machines

Icesta ice factory, integrated with a Vivid H-M Interactive Feature, cools your Concrete ready mix all automatically

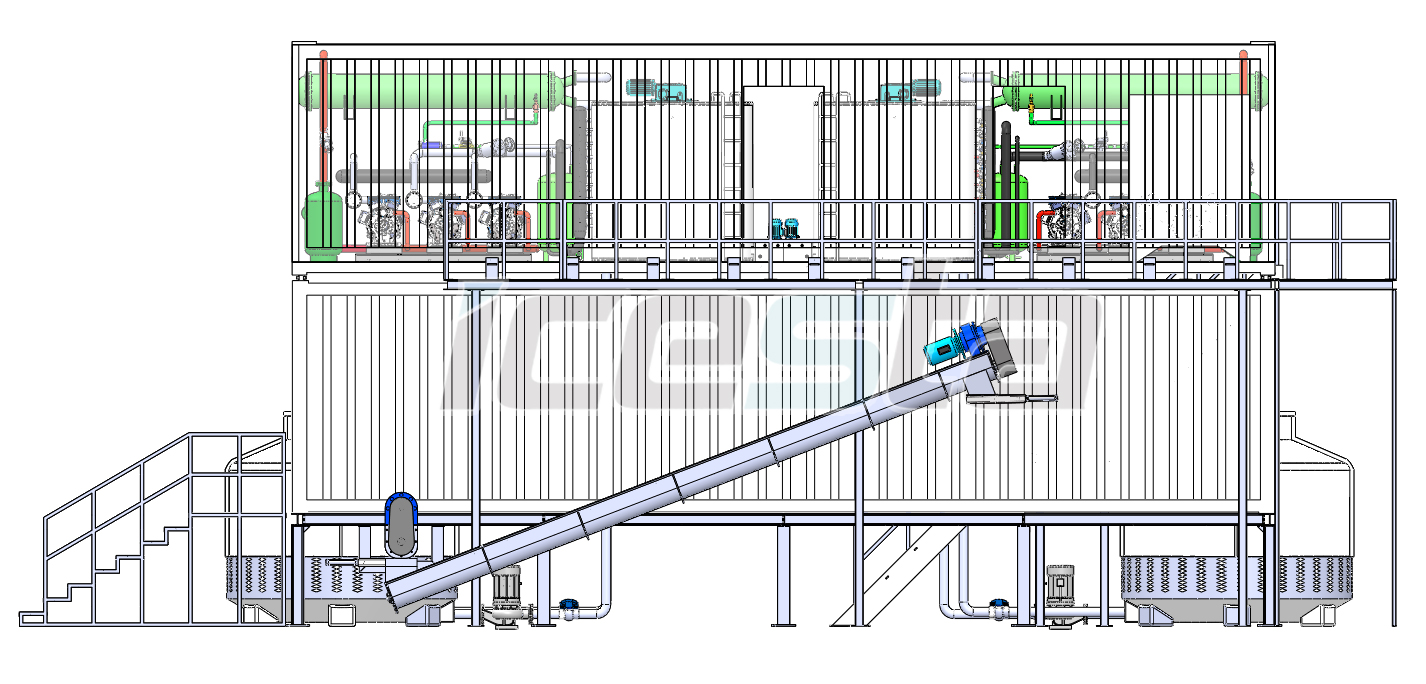

Raker style automatic ice storing & delivery system:

--------40HQ refeer container fitting with ice delivery system

A. Ice Sorage Bin: IFB20T automatic Ice raking and storage system of nominal capacity of 20ton; with insulated panel and inner assembled steel structure for Ice raking mechanism. It is movable and easy and free to transport, install and debug. This Ice storage will be manufactured in the factory and then transported to the work site for assembling

With Ice Raker & Ice Screw Conveyors

One cold room with rake system(as following pictures)

The Automatic Ice Storing Bin is refurbished from 40FT Reefer Container (5-8 years) is insulated in an integrated way. The temp controlling & defrosting system is controlled by ICESTA control system. And refrigeration Unit System is normally from Carrier or Mitsubishi.

B. Air Cooler installed on the top inside the storage bin, keeps the inner temp at -8degrees;

Ice raker inside loosens and pushes the ice hill to the outlet point of the ice storage bin

There is an induction mechanism for ice level detection, which helps keep the ice raker over the ice hill at all times.

C. Ice raker inside for keeping ice forwardering

During the ice flaker running, ice raker reverse to turn over the ice mound, which makes those dropping ice spread over the ice storage bin and the ice elevator which fixed with up and down limit as well as safety protection switch will automatically adjust the raker vertical height.

D.The screw conveyor under the ice storage

The screw conveyor below the ice deflector take charge of the ice which raked out from bin delivering to the snow maker

SNOW MAKER WITH BLOWING

Making snow from flake ice then blowing snow to 15-meter distance.

TYPE B -Making snow from slurry ice

For making more softer snow, but more suitable for bigger ski resort. Please contact for more details

Project references:

Window of the World

Shenzhen Window of the World

Shenzhen Window of the World

Shenzhen Window of the World

Snow making

USA SNOW PARK ( 2X 50T/DAY)

Snow making