Integrated Turnkey Project Solution

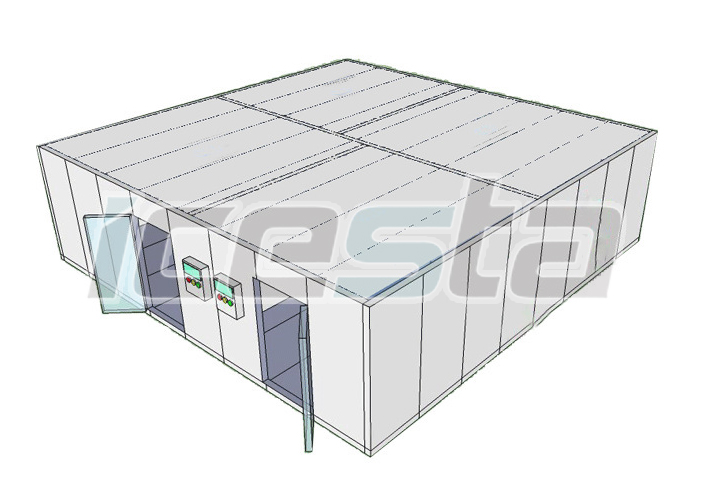

Complete Set of "Frozen Factory"

--------------All-In-One Automated Modular Solution

Blast freezer & Tunnel Freezer & Cold room

Over the past 15 years, ICESTA's strong R&D and engineering teams have continuously provided customers with first-class customized freezing solutions and complete-set Turnkey projects.

Industry Application

ICESTA All-In-One Automated Modular freezing solution consists of Quick freezing & Storing

involves:

Aquatic product processing

Slaughter processing

Vegetable distribution and preservation

Supermarket freshness

Aquatic product market preservation

Marine fishery

Slaughter processing

Vegetable distribution and preservation

Aquatic product processing

Before Solution Designing

Communication before scheme design:

ICESTA’s Freezing Solution has a very rigorous design process and PMP Project Management Procedure (please refer to the link menu “Procedure Flowchart & PMP System”). The following important communications must be made before the design of the scheme:

1.Application products/industries:

Aquatic product processing, slaughter processing, vegetable distribution and preservation, Supermarket freshness, aquatic product market preservation, marine fishery etc.

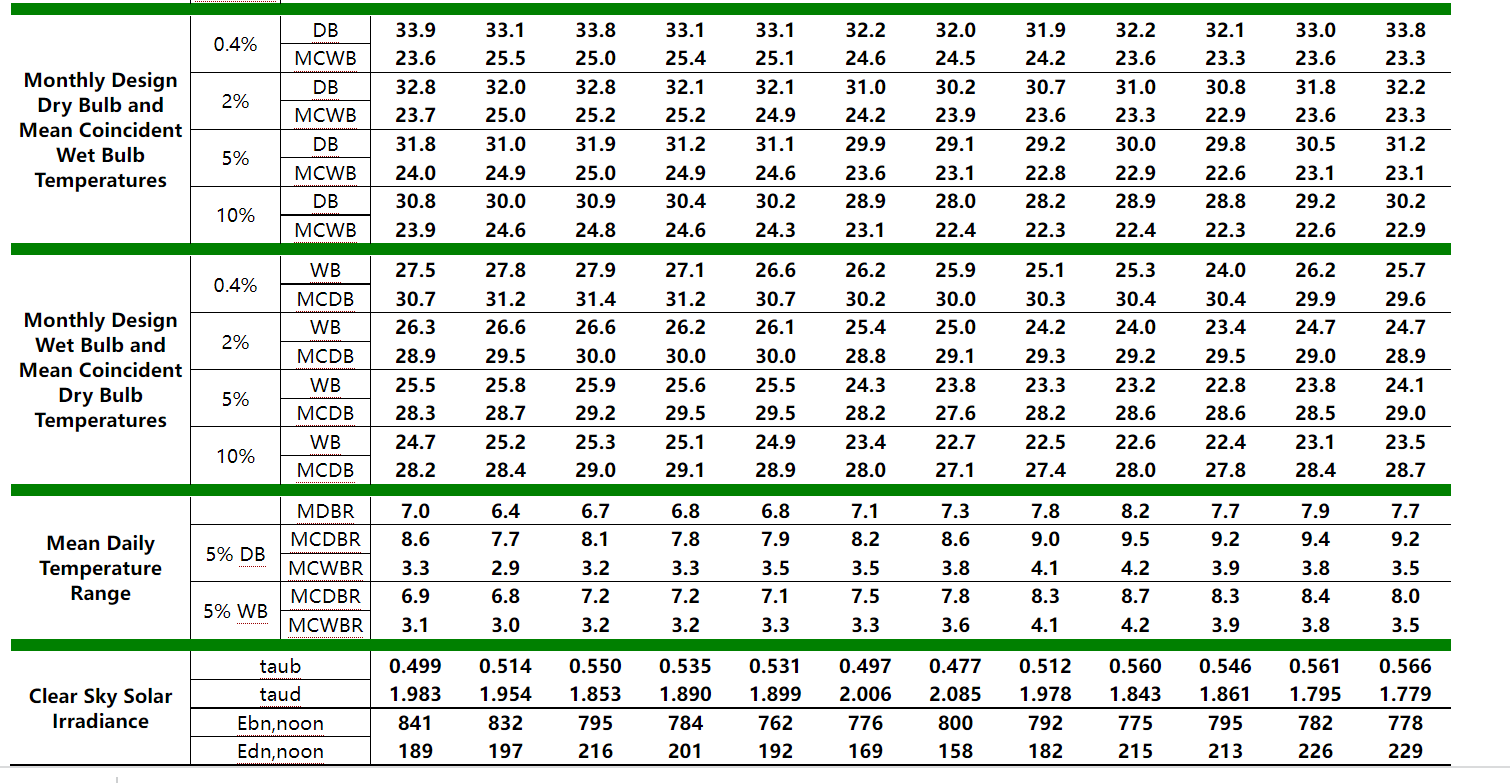

2.On-site environment:

use area (national area, climate), workshop size, installation environment (open air, outdoor, indoor), product quantity, product temperature (input temperature and output temperature etc. ), ambient temperature (maximum air temperature, minimum air temperature), air salinity, wet bulb temperature, etc.

For example, the web bulb temperature effect the technical selection of evaporative condenser

3.Use requirements:

product quantity, product temperature (input temperature and output temperature etc. ) Freezing time etc.

4.Technical requirements:

Cooling method (air cooling, water cooling, evaporative cooling), voltage requirements (pay special attention to special voltages: 380V 3P 50HZ, 220V 3P 60HZ, 440V 3P 60HZ, 480V 3P 60HZ, 380V 3P 60HZ), materials, compressors and other important components brands etc., need to be analyzed for specific products.

Solution Design & Parts Description

After the customer’s demand confirmed,our technical team recommend the most suitable Freezing system/Cold room, design the scheme and program, then ICESTA sends the detailed proposal.

* Examples ----

A.Cold room Solution for Pharmaceuticals storing in hospital.

1.Vaccine Storage; can be used to store vaccines, pharmaceuticals, etc.

2.Drug cold storage: used to store drugs and biological products, etc.

3.Blood Storage: can be used to store blood, pharmaceutical biological products, etc.

4.Low temperature insulation Storage: preservation of plasma, biological materials, vaccines, reagents, etc.

5.Ultra-low temperature Storage: can be used for semen, stem cells, plasma, bone marrow, biological samples, etc.

B.Cold room solution for Vegetables and fruits.

1. Vegetables can be stored for a long time, such as grapes for 6 months, apples for 8 months, garlic moss for 10 months, etc. Because of the long fresh-keeping period, they can also be sold off-season and improve the economic benefits of agricultural products. Moreover, the quality of fruits and vegetables after storage is as fresh as before, and the total loss is less than 5%;

2. The cold storage is easy to operate, with advanced equipment, microcomputer control temperature, automatic startup and shutdown, no need for special supervision;

3. The fruit and vegetable fresh-keeping warehouse has a wide range of applications, and can store various fruits, vegetables, flowers, seedlings, etc. in the north and south of my country;

4. It is not subject to environmental and geographical restrictions, and can be stored fresh for vegetables with different seasons.

C.Quick freezing of all kinds of food, poultry and seafood.

Blast freezer and Tunnel Freezer

The construction of quick-freezing cold storage is generally used in conjunction with the design of low-temperature refrigerators and ultra-low temperature cold storages. Quick-freezing reduces the temperature of items below the temperature of microbial growth and activity, and resists the growth of microorganisms and their biochemical reactions. Simply put, the function of the construction of the low-temperature quick-freezing warehouse is to quickly freeze the stored items and resist a series of reactions of the items.

What are the characteristics of the construction of quick-freezing cold storage?

1. Use more advanced refrigeration technology and insulation board manufacturing technology.

2. Perfect engineering design, advanced production technology, and strict quality assurance management ensure that products are checked at every level of production, so that user requirements can become reality.

3. The thickness of the warehouse plate is generally 150mm and 200mm. The board is filled with polyurethane thermal insulation material. Both sides are plastic-coated color steel plate or stainless steel plate. The color steel plate surface is processed into invisible grooves, which are light in weight, high in strength and good in heat insulation performance , Anti-corrosion, anti-aging, the storage board is easy and quick to assemble, it is one of the better materials for the cold storage insulation storage body.

4. The cold storage adopts advanced microcomputer control system and advanced control method, and the liquid crystal displays various parameters such as temperature, boot time, defrost time, fan delay time, alarm indication and so on. The operation is simple and the user is very convenient to use.

Product advantages

1. The standardized panel is 100 mm wide and 2 meters to 10 meters high. Cold storage board thickness specifications: 60, 75, 100, 120, 150, 180, 200mm;

The thickness of the warehouse board is generally 100mm, the double-sided is plastic-coated color steel plate, and the color steel plate surface is processed into an invisible groove, which is light in weight, high in strength, good in heat insulation, corrosion resistance and aging resistance. One of the better materials for thermal insulation storage body;

The library board insulation material is integrally formed with lightweight polyurethane foam with thermal insulation properties.

2. The double-sided color steel plate adopts advanced eccentric hooks and groove hooks, and the eccentric connection method realizes the close connection between the storage board and the storage board. T-shaped panels, wall panels, and corner panels can be assembled in any space. Simple and practical, energy saving and environmental protection.

3. Electric control part: The electric control box outside the medical cold storage has the function of automatic switching of dual control circuits, which usually refers to (conventional power supply and backup power supply).

4. Features: Control the automatic switching between the main compressor and the auxiliary compressor, digital display of the temperature in the warehouse, automatic monitoring, regulation, display, and temperature upper and lower limit alarm functions. To record the temperature, a more advanced temperature and humidity recorder is used, and an ultra-low temperature mobile phone short message automatic alarm system can be provided for special users to realize the unattended state throughout the process.

5. Refrigeration part

Cold storage refrigeration equipment: mainly the selection of cold storage compressors and evaporators. Under normal circumstances, small refrigerators mainly use fully enclosed fluorine refrigeration compressors. Due to the small power of the fully enclosed compressor, the price is relatively cheap, the equipment runs smoothly, the energy consumption is low, and the failure rate is low. It is the preferred unit for cold storage at present.

1)High-efficiency silent air cooler

Standardized air cooler, fireproof junction box, silent fan, internal thread copper pipe, sine wave aluminum foil, new. Generation of heat exchanger products.

2)Europe/USA Imported door lock accessories

After years of practice, selected imported brand cold storage door locks are durable and worry-free, and the maintenance rate is extremely low!

3)Genuine imported accessories

Original imported valve parts such as French Danfoss, Italian castel, American sporland, etc., to escort the operation of your cold storage!

4)Original world famous brand compressors

Selected world-class brand compressors: Italian Refcon, German Bitzer, American Copeland and other compressors, so that there is no worries when using the cold storage!

5)Easy operation and maintenance

One-key startup and shutdown, automatic defrosting, 24-hour unattended intelligent operation!

6)Extremely low operating costs

Large and medium-sized cold storage use piston or screw parallel units, which have high system efficiency and lower operating costs, providing you with perfect energy-saving solutions.

Reference Cases

200 Tons capacity Blast freezer.

Low Temperature large capacity cold storage.

Low Temperature large capacity cold storage.

As the demand for global bases increases, the market prospects for this product are optimistic.