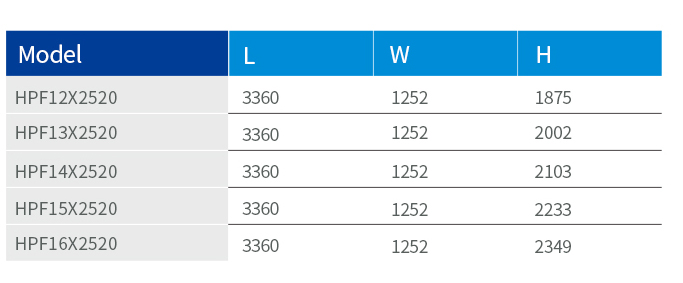

Plate freezers are commonly used for freezing brick-shaped products in mold or box. In plate freezers, refrigerant is allowed to circulate inside thin channels within the plates. The packaged products are firmly pressed between the plates. High rates of heat transfer can be obtained between the packaged product and the evaporating plates.

Plate freezers are commonly used for freezing brick-shaped products in mold or box. In plate freezers, refrigerant is allowed to circulate inside thin channels within the plates. The packaged products are firmly pressed between the plates. High rates of heat transfer can be obtained between the packaged product and the evaporating plates.

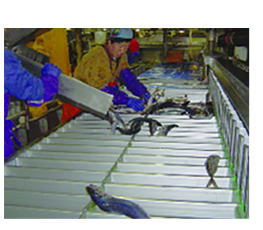

Suitable for solid bulk food, such as: fish, meat, vegetables; also suitable for food,Such as: fruit juice, milk products, concentrates, etc., pulp, etc.

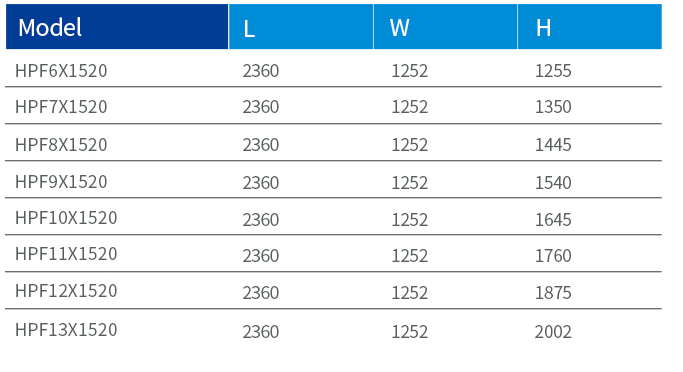

Thickness of evaporative plates:25mm;

Distance between plates:40-90mm.

※The specification is subjective to change without notice, please contacts alesman before placement of order.

※Tailored design is available for special requirements.

WA/WF Horizontal

*It is ideal to freeze fishes, shrimps, meat , poultry, offal, ready meal in trays or boxes.

*The refrigerant can be Freon,Ammonia or C02

*Made out of sea water resistant Aluminum, food grade. The 25mm thick Square aluminum plate gives high strength, high corrosion resistance and thermal conductivity. The plate is automatic welded and has minimum deformation.

*The enclosure is insulated with one piece of Polyurethane foaming to ensure robust structure and minimize the cold loss by eliminating the joints.

*The Square plate freezer' s enclosure is stainless steel. It can sustain the harsh marine environment and easy to clean.

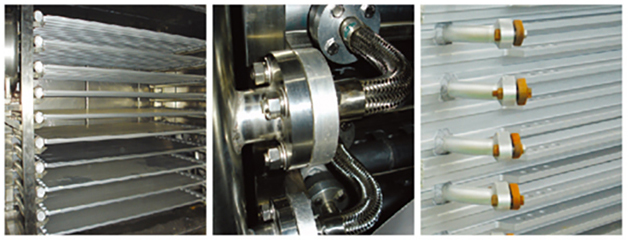

*PTFE Leak-free flexible Hose Joints, flanged or thread connections.

The hose is covered with 304L stainless steel braid.

High efficiency

The freezing plate is a professionally designed plate evaporator, ensuring uniform and smooth flowing of refrigerant,making the surface temperature of the plate uniform and consistent and realizing high heat transfer efficiency.

The freezing plate is an aluminum alloy plate,which is manufactured using the welding technology and equipment of American MLLER Company to ensure welding quality,plate leveling and small deformation.Theintegral plate is treated for anodic oxidation and a layer of uniform and compact oxide film is formed on the plate surface,so that the plate is resistant to corrosion,transfers heat uniformly and has good freezing effect.

The liquid feed and air return flow uses a single plate for liquid feed and air return, thereby realizing short flow and small flow resistance.

The liquid feed and air return manifold uses stainless steel materials to ensure the requirements of food safetyand sanitation are satisfied.

Reliable

Both the framework and the yoke are made of hot-dip galvanized materials or stainless steel sections and thus have strong corrosion resistance.

The liquid feed and air return pipes connected with the freezing plate all use stainless steel corrugated pipes,which fluctuate freely in low temperature environment, can be used frequently for long and have high reliability.

The professionally designed hydraulic system has multiple protective devices and thus can ensure long-termstable operation of the equipment.The oil pump is a high precision vane pump, which is characterized by compact structure,stable operation, low noise,small pressure flow pulsation and long service life.The cylinder is a stainlesssteel cylinder and oil seal is imported to ensure reliable operation of the hydraulic system.

Compatible

The refrigerants used in the standard design of the freezing plate include R717 and R22;R404A and R744 or other coolants can be used according to the customer's actual requirements.

The width design of the freezing plate considers convenient loading and unloading by operating personnel all the more.

Horizontal Plate Freezer is first generation of products of Nantong Square. lt's widely used in aquatic producits.fisheries and meat products processing.

Main structure and performance:

※ Unique one-piece insulated enclosure with better insulation and strength.

※Full stainless steel enclosure with good appearance, easy for cleaning.

※Aluminum-alloy evaporative plate with better freezing efficiency.

※※Separate liquid supply and suction for each plate, even supply with high efficiency,better freezing performance.

20 years professional Team & Excellent Turnkey ICE & Cooling Solution Designer,Manufacturer, &Builder

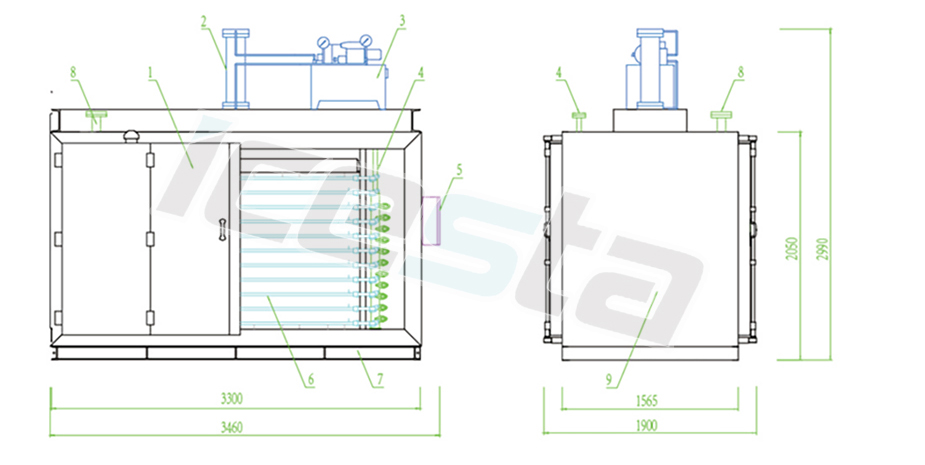

1.Door 4.Liquid line 7.Base frame

2.Hydraulic cylinder 5.Electrical control 8.Gas line

3.Hydraulic station 6.Plate 9.Insulated enclosure

Since 2007, ICESTA products have been sold to more than 80 countries around the world, and provide distributor services in many regions.

Technology, change the world, innovate, and subvert tradition. We are committed to making people's production and life more convenient, efficient and beautiful

Feel free to contact us

ICESTA has always adhered to the philosophy of “UNITED, PRECISION, INTERNATIONALIZED & OUTSTANDING”, from professional refrigeration team, strict quality system, efficient management mode, global development strategy, and customer-oriented. The business purpose of all is combined with this inner concept, thus laying a solid foundation for the realization of broad corporate goals.