ICESTA Tube Ice Making Machine is designed with innovative technology to provide high ice output, reliable performance, and humanized design. The tube ice produced is crystal-clear and free of powder, with a longer melting time compared to flake ice, making it ideal for cooling in uninsulated environments. With over 20 years of experience in refrigeration and ice making, ICESTA ensures efficient ice production, smooth ice removal, and stable operation through continuous product innovation.

Our company, a leading manufacturer of high-performance tube ice making machines, prides itself on delivering top-quality products that exceed customer expectations. With a commitment to innovation and cutting-edge technology, we ensure that our machines are efficient, reliable, and built to last. Our team of experienced engineers and technicians are dedicated to providing exceptional service and support to help our clients achieve their ice production goals. With a strong emphasis on quality, reliability, and customer satisfaction, we are proud to be a trusted partner in the ice-making industry. Choose our machines for superior performance and peace of mind.

Our company is a leading innovator in the field of ice making technology, with a focus on delivering high-performance tube ice making machines to meet the demands of various industries. With years of expertise and dedication to quality, we are committed to providing our customers with reliable and efficient solutions that improve their operations and productivity. Our company values integrity, customer satisfaction, and continuous improvement, ensuring that our products consistently meet the highest standards of performance and durability. Choose our high-performance tube ice making machine for unmatched reliability and excellence in ice production.

More customers have recommended ICESTA Ice System to be their choices to purchase .

Product Introduction

ICESTA is providing the world Excellent Tube ice solutions with high ice output, reliable performance and humanization design.

Tube ice is in the shape of crystal and powderless tubes. Comprared with flake ice, the melting time of tube ice is longer, and it is more suitable for cooling in an unisulated environment. Tube ice is comparatively solid and less prone to ice lumps, so it is more suitable for long distance delivery.

Application Industry

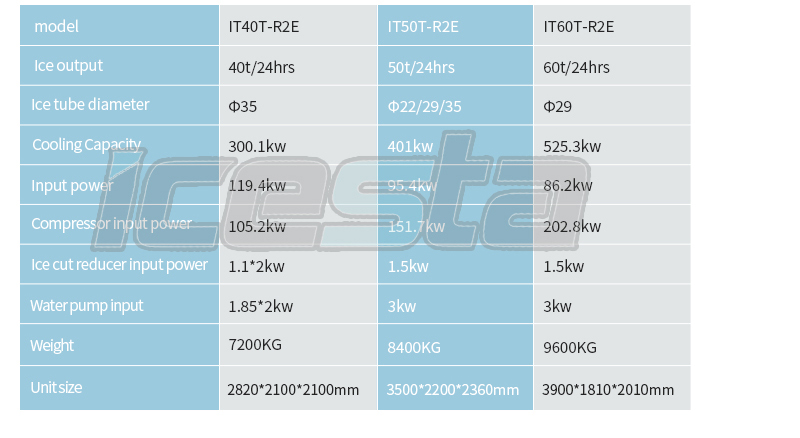

Thetechnical data based on 30-℃ambient temp.20Cwater inlet temp.

The evaporating / condensingtemp.-15C/40-C(Air-coole) 38-C(Water cooled)Powersupply: 3P/380V/50HZ(3P /220/60HZ,3P/280V/60HZ,3P/460V/60HZ Optional)Refrigerant R404A(R22R17 R507 is optional)

lce tube diameter: $22,429,p35,p42 is optional

Technology, change the world, innovate, and subvert tradition. We are committed to making people's production and life more convenient, efficient and beautiful.

ICESTA is providing the world Excelent Tube ice solutions with high ice output, reliableperformance and humanization design.

Drawing Display

The ICESTA team has used more than 20 years of experience in refrigeration and ice making to continuously innovate products to achieve higher efficiency, more stable operation, smoother ice removal and ice production.

Advantage

ADVANTAGES OF ICESTA TUBE ICE PLANTINNOVATIVE DESIGN FOR GENERATOR

1.Innovative manufacturing artwork has been adopted.The kce stripping surface issmooth as a mirror.That has tremen-douslyincreased ice stripping efficiency andenergy-efficiency ratio.

2.The ice cuttercan be easily dismantled and replaced as a whole.

3.Compared with peersJCESTAevaporator canformeven water membrane more effectively.That makes more even andcrystal ice tubes

4.The upper and lower freezing water reservoir is openly structured,which helps a lot withcleaning anddisinfection.

5.ICESTAice plant adopts an optimizeddriving structuraldesign, which ensures both simplestructure and high reliability.

6. ICESTAcustomizes a reasonable design of ice plantsuitable for convenient containertransportation for oversea clients.

7.Deice just need 130-200s.

PATENTED H-M INTERACTIVE INTELLIGENTCONTROL SYSTEMWITHToUCH-SCREEN:

The working status of the ice system display alive in screen

2.Setting stop-time at will.

3. All possible failure and trouble-shooting is programmed in.

4.Local time could be set

All great works are moving in countless details, and every high-quality ice machine is precisely carved out of the details.

Auxiliary Equipment

Optimal industrial application: lce packing

Components:

1.Buffer Storage Bin (ranging from 50OKG to 2000KG)

2.Built-in delivery screw

3.Dual control system (Manual and foot pedal);

Foot pedal can start and stop at will, which is nearly a semi automatic packing machine.

PACKAGE UNIT OF TUBE ICE MAKING, DELIVERING, PACKING,ICE BAGS CONVEYING.

Customer-Oriented design.Our consideration and,innovation reach everywhere.

Engineering Case

Since 2007, ICESTA products have been sold to more than 80 countries around the world, and provide distributor services in many regions.