The Ice Flake Evaporator boasts a lifespan of over 15 years, providing long-lasting durability and reliable performance. Made from top-quality materials, this evaporator is resistant to rust and leakage, ensuring a worry-free operation for years to come. Its innovative design and high-quality construction make it a top choice for commercial refrigeration needs.

At our company, we pride ourselves on serving our customers with high-quality products that are built to last. The Ice Flake Evaporator we offer boasts a lifespan of over 15 years, ensuring durability and longevity. With a promise of no rust or leakage, our evaporator is designed to provide reliable and efficient performance. We are dedicated to serving our customers by delivering top-notch products that meet their needs and exceed their expectations. Trust us to serve you with excellence and dependability, making your experience with our products truly exceptional.

At Ice Flake Evaporator, we serve with a commitment to quality and durability. With a lifespan of over 15 years, our evaporator is designed to withstand the test of time. Our product is built to last, with no risk of rust or leakage, ensuring long-term performance and reliability. We pride ourselves on providing a high-quality solution that meets the needs of our customers, delivering exceptional value and peace of mind. Trust in Ice Flake Evaporator to serve you with a product that exceeds expectations and stands the test of time.

PRODUCT INTRODUCTION

Who purchase the single Ice flaker evaporators?

1. Professional refrigeration contractors, flake ice machine manufacturers. As the tarrif to be charge for components is comparatively lower and the labor cost is low, purchasing of evaporators for assembly skid-mounted ice machine will help reduce the cost and increase profit.

2. End users who need replace old evaporator

3. Factories which have a central ammonia refrigeration system. Like large scale chemical processing facilities and Aquatic products processing facilities,Meat Processing factory etc

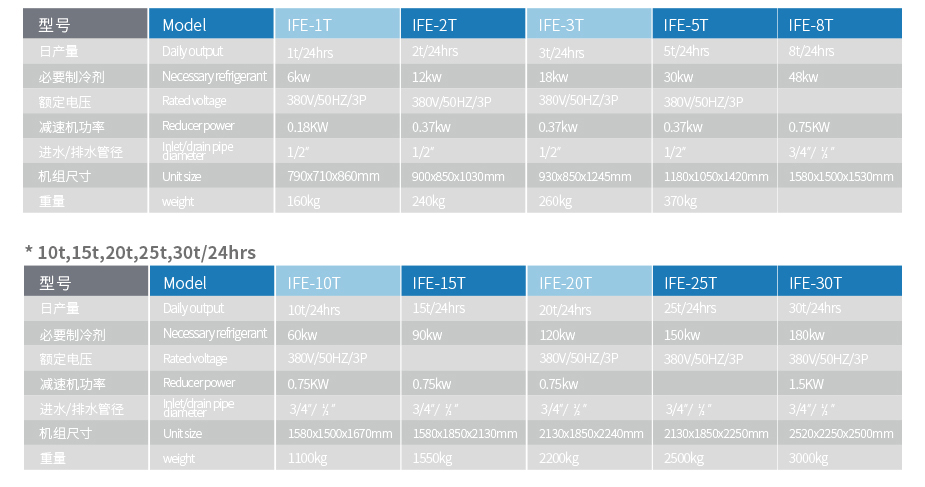

Scope of Evaporator Capacities

Daily production Capacity: 500kg – 60 T (for overseas customers, the maximum capacity is 40T due to the max height restriction of container).

* Classification of Ice flaker evaporator

*Power supply: 380V/3P/50HZ, 220V/3P/60HZ, 380V/3P/60HZ, 460V/3P/60HZ

*Ambient temperature 35℃

*Water supply Temp 20℃ ( quality)

*Extreme working condition environment: 5℃~40℃, water supply 5℃~30℃

*Refrigerant: R22, R404A, R507A

More and more Coling or temp.Reduction industry used the ice machines to meet their higher technic request due to their deeper knowledge about this equpment.

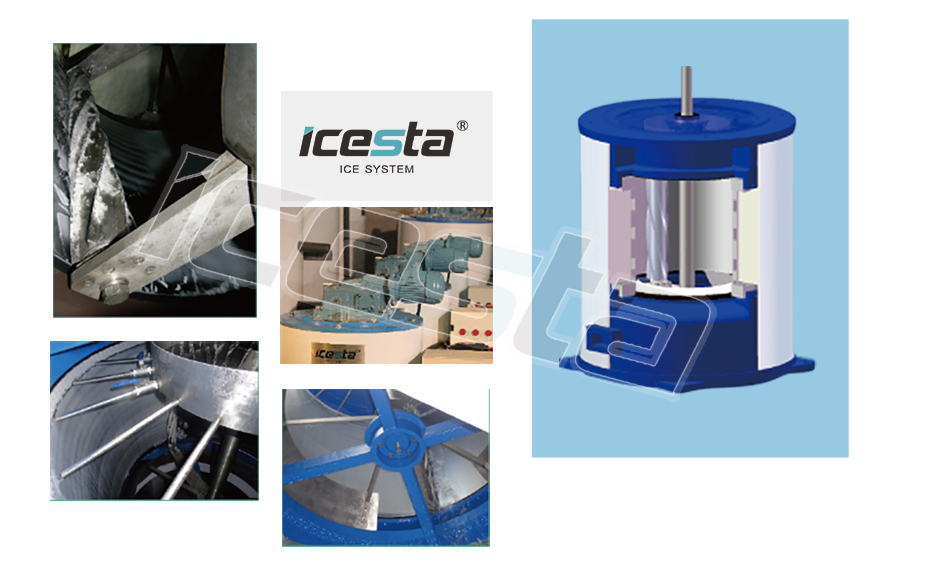

Flake ice evaporator is the key part of ice flake machine,structured as a vertical cylinder. It is comprised by the following major ice making components:

Ice maker drum, blade, main shaft, water distributing pan, water shield,etc.

Their movement is coordinated by the reducer, which moves at a low speed anticlockwise. Water is sprayed into the water distributing pan which distributes water evenly onto the freezing surface of the evaporator. Water film thus formed conducts heat exchange with the low temperature refrigerant inside the evaporator chambers, and turns into a thin layer of ice on the freezing surface of evaporator, which is crushed into flake ice and drops into ice storage bin through the ice dropping orifice of the evaporator.

The water that is not frozen into ice returns to cold water tank of the evaporator and is pumped into the water distributing pan for the next ice forming cycle.

Characteristics

Rigorous pick-up of raw material. Not every kind of Stainless Steel is the same in terms quality on the market. When we choose stainless steel, we use the material of high quality with Qualified Material Certificate only.

*Strict ERP Quality control system

*Prominent Technology of Welding Detecting Ray

*Ice Blade weldless Forming

*Excellent Heat treatment of stress relief by annealing

*Prominent X-radial welding detecting technics

*Chromium Coating (carbon steel )

*Quantity & loops of refrigerant chambers designed Stringently

*A multiple of cleaning jobs for the refrigerant chamber

*Evaporator never meet deformation

*No refrigerant leak

*Ice scraping smoothly

ICESTA First-Class Craftsmanship

Key points of Quality control of flake ice machine

Pontos-chave de controlo de qualidade de uma máquina de gelo em flocos

1. Evaporator Machining and Processing

*Spiral Refrigerant Chamber Design of the evaporator, compared to other designs, assures that refrigeration oil mixed in refrigerant gas return to compressor, and in the same time, dry evaporating style of ICESTA evaporator will eradicate the damage of compressor slugging.

* When the refrigerant chambers of the evaporator have been properly welded, a heat treatment of stress relief by annealing is done to eradicate effectively the hidden danger of evaporator deforming.

* Chromium coating of evaporator freezing surface (carbon steel only) will enhance hardness and wearability.

2. Ice Blade Machining and Processing

Maquinaria e Processamento da Lâmina de Gelo

Ice blade is machined into a spiral type scraper from a single stainless steel bar. Compared to ice blades made through welding, the intensity is much more higher. And ICESTA ice blade is free from internal stress caused by welding. Spiral type ice blade applies force onto the evaporator freezing surface evenly, which will lengthen dramatically the life time of both ice blade and evaporator.

The ICESTA team has used more than 20 years of experience in refrigeration and ice making to continuously innovate products to achieve higher efficiency, more stable operation, smoother ice removal and ice production.

Technology, change the world, innovate, and subvert tradition. We are committed to making people's production and life more convenient, efficient and beautiful

FAQ

1.Questions before quotation

A. Would you make ice from seawater, saltwater or freshwater?B. Where and when would the machine be installed roughly?The ambient temperature and water inlet temperature?C. What’s the power supply?D. What is the application of the flake ice produced?E. Which cooling mode would you prefer to? Water or air ,Evaporative cooling?

2.Installation & commissioning

A. Installed by customers according to the manuals, online instructions and live video conference of ICESTA.B. Installed by ICESTA engineers.a. ICESTA would arrange 1~3 engineers based on the projects to the installation sites for the final supervision of all installations and commissioning.b. Customers need to provide local accommodation and round-trip ticket for our engineers and pay for the commissions. US Dollars 100 per engineer per day.c. Power, water, installation tools and spare parts need to be ready before ICESTA engineers arrive.

3.Failure Claim procedures

a. Detailed written failure description is required by fax or by mail, indicating the relevant equipment information and detailed description of failure.b. Relevant pictures are required for failure confirmation.c. ICESTA engineering and after-sales service team will check and form a diagnosis report.d. Further trouble-shooting solutions will be offered to customers within 24 hours after receiving the written description and pictures

Advantages

1.Permanent technical support & consultation all life long for the machines.

2.Over 25 engineers for instant after-sale services and more than 15 are available for serving overseas.365 days X 7 X 24 hours phone / EMAIL assistance

3.Any failure occurred within the period due to our responsibility, ICESTA will supply the spare parts for free.

4.ICESTA provide full technical support and training courses after equipment installation and commissioning.

About Brother Ice System

Shenzhen Brother Ice Systems Co., Ltd. is (ICESTA for short) located in Shenzhen of China. Our company is a professional manufacturer and exporter specializing in designing and supplying innovative ice solutions worldwide with our own ICESTA ice machines.With a senior professional refrigerating team, modern operating conception, ordered efficient management model, and global strategy, ICESTA has founded a substantial base to tend towards the global market, then play an important role in the fresh keeping and cooling in the field of aquatic food & meat processing, ocean-going fishing, fowl slaughtering, concrete construction project, large supermarket and chain stores, dye chemical industry, mining and medical facilities.In line with our customer-oriented philosophy, ICESTA management is actively aligning the business structure to well meet customers' needs with a wide range of products, excellent quality as well as credible service. As a professional exporter, ICESTA will strive to create maximum value for our esteemed clients.

The application of the QC process is crucial for the quality of the final product, and every organization needs a strong QC department. evaporator for ice machine QC department is committed to continual quality improvement and focuses on ISO Standards and quality assurance procedures. In these circumstances, the procedure may go more easily, effectively, and precisely. Our excellent certification ratio is a result of their dedication.

In essence, a long-standing evaporator for ice machine organization runs on rational and scientific management techniques that were developed by smart and exceptional leaders. The leadership and organizational structures both guarantee that the business will offer competent and high-quality customer service.

Yes, if asked, we will supply relevant technical details regarding ICESTA Ice System. Basic facts about the products, such as their primary materials, specs, forms, and primary functions, are readily available on our official website.

The buyers of evaporator for ice machine come from many businesses and nations around the world. Before they begin working with the manufacturers, some of them may reside thousands of miles away from China and have no knowledge of the Chinese market.

Regarding the attributes and functionality of the evaporator for ice machine, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

In China, ordinary working time is 40 hours for employees who work full time. In Shenzhen Brother Ice System Co., Ltd, most employees work abiding by this kind of rule. During their duty time, each of them devotes their full concentration to their work so as to provide customers with the highest-quality Block Ice Machine and an unforgettable experience of partnering with us.