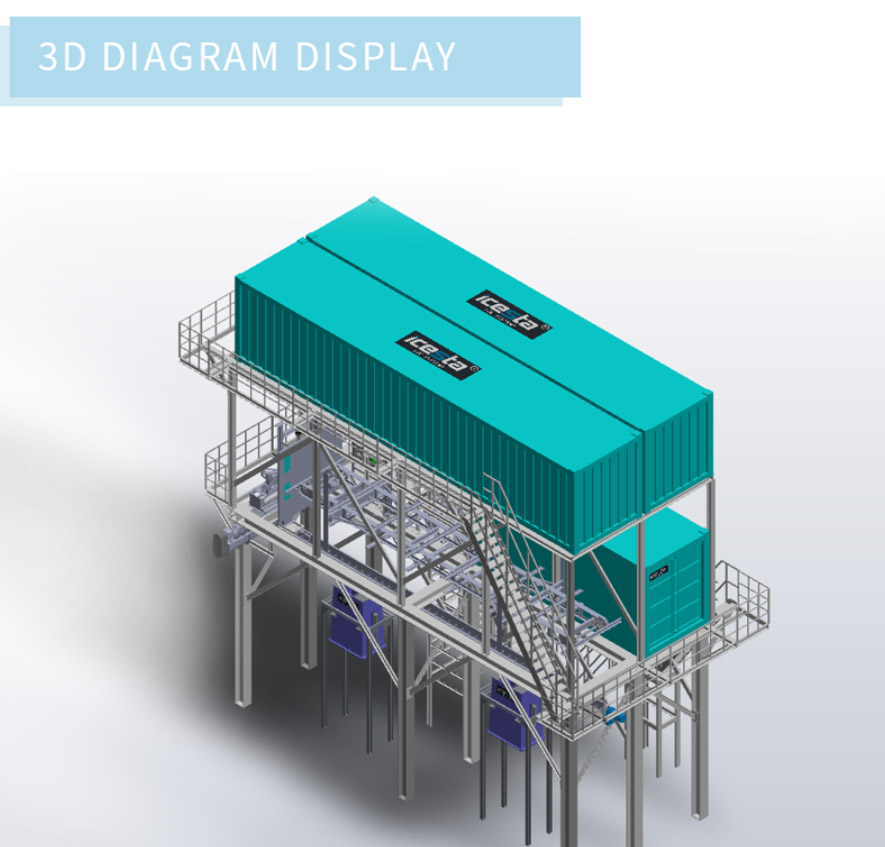

The ICESTA 120 Ton Containerized Ice Flake Machine is a robust and reliable product designed for severe working conditions. With a mobile type storage room, ice discharge and delivery augers, and a smart ice dose system, this container ice machine is highly efficient and durable. It features environmental-friendly refrigerants, multi-stage cooling, and a stainless ice tank for exceptional ice and cold water production capabilities, making it a top choice for cooling or temperature reduction industries worldwide.

Icesta is a leading provider of refrigeration solutions, specializing in the design and manufacture of high-quality ice flake machines. Our 120 Ton Containerized Ice Flake Machine is a testament to our commitment to innovation, efficiency, and reliability. With a focus on energy efficiency and sustainability, our machines are designed to meet the needs of various industries, from fishing to food processing. We pride ourselves on delivering superior products that exceed customer expectations, backed by our team of dedicated experts who are always ready to provide exceptional service and support. Choose Icesta for top-of-the-line ice flake machines that guarantee performance and durability.

Established in 2007, Icesta is a leading manufacturer of ice making machines, with a specialization in containerized ice flake machines. Our 120-ton capacity machine is designed for industrial use, providing a reliable and efficient solution for businesses requiring large quantities of ice. We are committed to delivering high-quality products that meet the unique needs of our customers, ensuring reliability and performance. With a focus on innovation and customer satisfaction, Icesta continues to be a trusted provider in the ice making industry, offering solutions that are both practical and cost-effective. Choose Icesta for your ice making needs and experience the difference in quality and service.

1.Fastest melting time of Flake Ice compared to any other ice.

2.Shortest mixing time as Flake Ice melts Rapidly

3. Longer lifespan of the Batch plant equipment and cost saving due to short mixing time

4.The cooling energy is 100%e or Even Higher as the flake ice is Subcooled (-7 degrees)

5. Due to the dryness, the cooling input of flake ice can be accurately calculated and itseffects on the mixture’s temp is quickly apparent

6.Flakes remain crisp and do not stick together nor do they form Blocks

7.Flakes are free Flowing

8. Easy to be Stored leveled inside a refrigerated lce Rake System

9.Easy to Transport via screw conveyors or Blowing System

l0.No defrost losses as subcooled flake ice is sheared from freezing surface by the iceremoval tools

ICESTA Auto lce Storage Room

1 .Mobile type, starting from 20 metric tons up to 100 metric tons

2.Robust steel used for the ice rake assembly and Ice Rake Hoist System

3.Reliable Sensors and Limit Switches to control the movement of Auto Ice Storage Room Automatically

4.Efficient Air cooler to keep the room temp down to -l0 degrees

5.100- 150 mm thickness Pancls keep the cold inside the room

ICESTA lce Discharge Auger and Delivery Auger

1.Robust design suitable for severe working conditions

2.Single and Dual Screw Design, with a designed delivery rate of 25-40T per Hour

3.Renowned Gearbox with Motor ensures the high quality of ICESTA Brand.

4.Single or Dual lce outlet for one or two ice outlet, which can deliverice at sametime to twin batch plants.

5.Stainless material or Galvanized Steel optional.

ICESTA Smart lce Dose System

1.Robust design suitable for severe working conditions

2.Ice Hopper volume up to 500KG

3.Renowned Gearbox with Motor ensures the high quality of ICESTA Brand:; 4.Accurate lce Scale system

5.Stainless material or Galvanized Steel optional

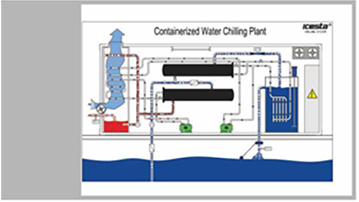

ICESTA ICE/COLD WATER PLANT

2. Multi-stage cooling from +45℃ down to less than 1℃ by 2 semihermetic screw/reciprocating compressors with economizer performance.

3.Plate heater exchanger as evaporators (corrosion-free) for high-efficiency heat transfer.

4.Stainless Ice tank (corrosion-free) for the ice bank system.

5.Evaporative condensers (corrosion-fee) for High efficiency heat rejection.

6.With our special designed multi-stage cooling system for fresh water cooling of concrete batching plants extraordinary high COP’ s can be achieved;

| Ice Watet Piant | IWP110T | IWP130T | IWP150T | IWP180T | IWP200T | IWP250T | IWP270T | IWP320T | IWP400T | IWP432T | |

| Max Concrete Production | M³/Day | 700 | 800 | 930 | 1100 | 1340 | 1530 | 1680 | 2000 | 2450 | 2690 |

| Ice Water Production | M³/Day | 110 | 130 | 150 | 180 | 200 | 250 | 270 | 320 | 400 | 432 |

| Total Water Flow | M³/H | 4.6 | 5.4 | 6.25 | 7.5 | 8.3 | 10.4 | 12.25 | 13.4 | 16.7 | 18 |

| Recommended Storage Capacity of Water Tank | M³ | 50 | 60 | 90 | 100 | 100 | 120 | 130 | 150 | 200 | 220 |

| Installed Ref. Power | KW | 240 | 280 | 320 | 380 | 460 | 525 | 575 | 715 | 834 | 920 |

| Electric Pawer Consumption | KW | 63 | 70 | 82 | 95 | 100 | 130 | 145 | 178 | 215 | 235 |

| Cold Watet Piant | CWP110T | CWP130T | CWP150T | CWP180T | CWP200T | CWP250T | CWP270T | CWP320T | CWP400T | CWP432T | |

| Max Concrete Production | M³/Day | 700 | 800 | 930 | 1100 | 1340 | 1530 | 1680 | 2000 | 2450 | 2690 |

| Ice Water Production | M³/Day | 110 | 130 | 150 | 180 | 200 | 250 | 270 | 320 | 400 | 432 |

| Total Water Flow | M³/H | 4.6 | 5.4 | 6.25 | 7.5 | 8.3 | 10.4 | 12.25 | 13.4 | 16.7 | 18 |

| Recommended Storage Capacity of Water Tank | M³ | 50 | 60 | 90 | 100 | 100 | 120 | 130 | 150 | 200 | 220 |

| Installed Ref. Power | KW | 198 | 234 | 270 | 324 | 360 | 450 | 485 | 576 | 720 | 780 |

| Electric Pawer Consumption | KW | 51 | 58 | 68 | 75 | 85 | 110 | 130 | 170 | 190 | 200 |

Application Industry

More and more Coling or temp.Reduction industry used the ice machines to meet their higher technic request due to their deeper knowledge about this equpment.

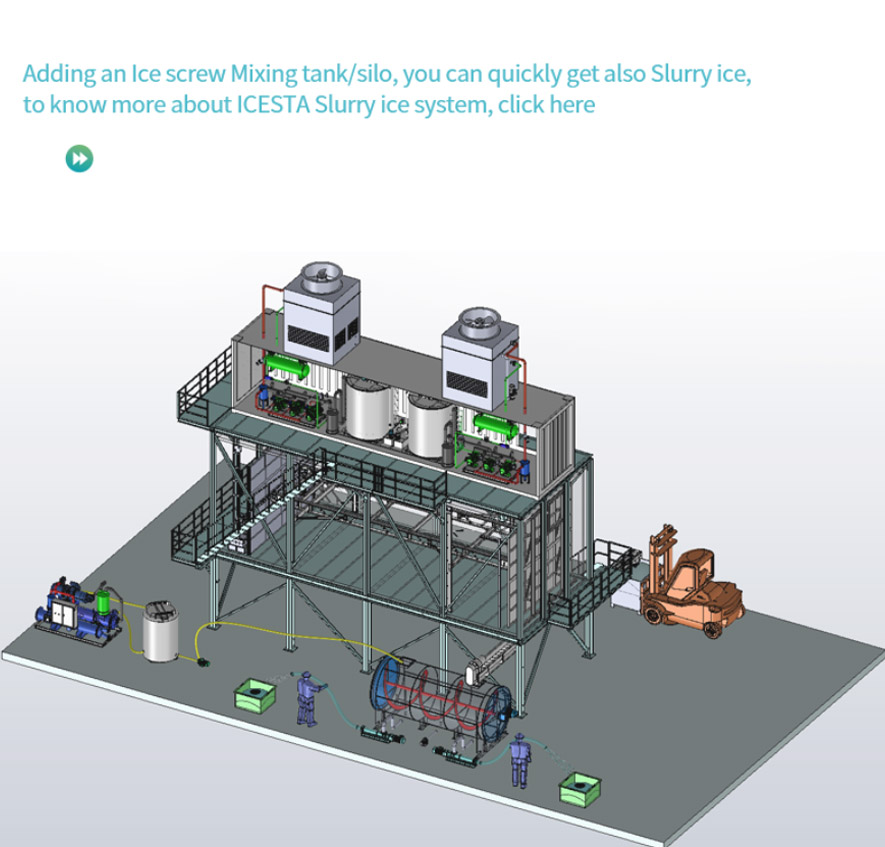

Auxiliary Equipment

Fully automatic system "storage" and "ice delivery" integration project

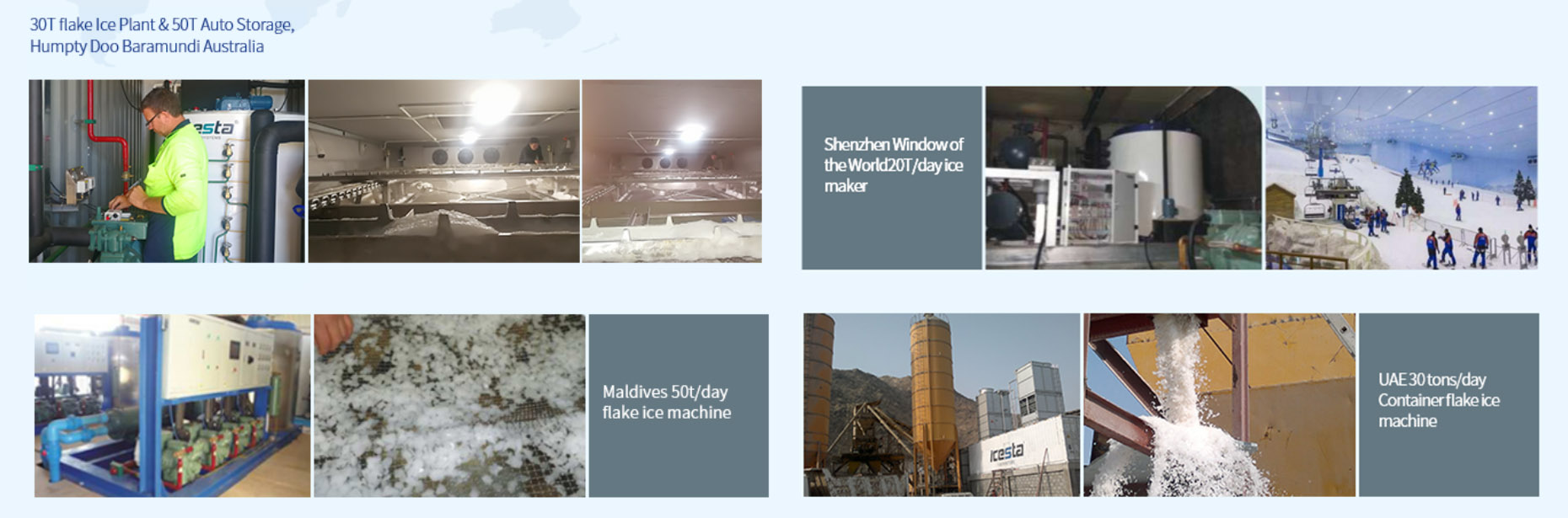

Engineering Case

Since 2007, ICESTA products have been sold to more than 80 countries around the world, and provide distributor services in many regions.

Picture Display

Technology, change the world, innovate, and subvert tradition. We are committed to making people's production and life more convenient, efficient and beautiful

Product Hot Sale

ICESTA

20 years dedication in ice making technology to create excellence.

Shenzhen Brother Ice System Co., Ltd. ( ICESTA Brand), a well-known ice machine manufacturer and industry leader and pioneer in China.The product covers flake ice /Block ice machine, Tube ice /slurry ice/plate ice/cube ice machines, water

chillers,Plate/spiral/blast freezers, Automatic ice storing & delivery system with integrated container ice system,artificial snow making machine.etc

Experiences & History:

20-Years Team focus on innovative solution in Ice & Cooling technology.

17-Years Professional Manufacturer, Supplier of Excellent Turnkey ice & cooling projects.

Industry status& Reputation:

* TOP 3 of China industrial ice machine Brand with strong capability of R&D

* 20000㎡ Factory

* ISO 9001 , CE, PED, ASME (U.S ) Certificates etc

Technology & Management capability:

* 80+ patents Certificates

* High Technology enterprise Certificate

Services & Global Net:

* Export to 80+ countries

* Local service in 50+ countries with networks all over the world.

* 1-2 years warranty covers each component.

ICESTA Customers & Certificate

Packages & Service

Packages & Service

Regarding the attributes and functionality of the container ice machine, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

Regarding the attributes and functionality of the container ice machine, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

To draw in more users and consumers, industry innovators are continually developing its qualities for a larger range of application scenarios. Additionally, it can be customized for clients and has a reasonable design, all of which help grow the customer base and loyalty.

In essence, a long-standing container ice machine organization runs on rational and scientific management techniques that were developed by smart and exceptional leaders. The leadership and organizational structures both guarantee that the business will offer competent and high-quality customer service.

The buyers of container ice machine come from many businesses and nations around the world. Before they begin working with the manufacturers, some of them may reside thousands of miles away from China and have no knowledge of the Chinese market.

Yes, if asked, we will supply relevant technical details regarding ICESTA Ice System. Basic facts about the products, such as their primary materials, specs, forms, and primary functions, are readily available on our official website.