The ICESTA Flake Ice Plant offers exceptional efficiency in ice production, with a capacity ranging from 20 to 80 tons daily, making it ideal for various industries such as food processing, cold storage, and seafood preservation. Engineered with advanced technology, it features durable construction, low energy consumption, and a user-friendly control system that ensures consistent ice quality and ease of operation. With its compact design and reliable performance, the ICESTA Flake Ice Plant stands out as a robust solution for businesses seeking scalable and sustainable ice-making capabilities.

### Team Strength

At ICESTA, our strength lies in our dedicated and experienced team, committed to delivering top-notch ice production solutions. With experts in engineering, manufacturing, and customer service, we ensure that our Flake Ice Plant operates at peak efficiency, producing between 20T to 80T of ice daily. Our collaborative spirit fosters innovation, enabling us to continually enhance our technology while upholding quality standards. We prioritize customer satisfaction by providing tailored support and maintenance, ensuring seamless operation beyond purchase. Trust in our skilled team to deliver not only exceptional products but also enduring partnerships that strengthen your business's ice supply capabilities.

### Team Strength

At ICESTA, our strength lies in our dedicated team of experts who drive innovation and excellence in ice production technology. With a combined experience of over 20 years in the industry, our engineers and technicians are committed to delivering reliable and efficient solutions tailored to meet your ice needs. Our collaborative approach ensures that every aspect of the ICESTA Flake Ice Plant, from design to operation, reflects meticulous attention to quality and performance. Trust in our knowledgeable team to support you with exceptional service and expertise, guaranteeing you the highest standards of efficiency and productivity with our 20T-80T daily capacity flake ice production systems.

1.Fastest melting time of Flake Ice compared to any other ice.

2.Shortest mixing time as Flake Ice melts Rapidly

3. Longer lifespan of the Batch plant equipment and cost saving due to short mixing time

4.The cooling energy is 100%e or Even Higher as the flake ice is Subcooled (-7 degrees)

5. Due to the dryness, the cooling input of flake ice can be accurately calculated and itseffects on the mixture’s temp is quickly apparent

6.Flakes remain crisp and do not stick together nor do they form Blocks

7.Flakes are free Flowing

8. Easy to be Stored leveled inside a refrigerated lce Rake System

9.Easy to Transport via screw conveyors or Blowing System

l0.No defrost losses as subcooled flake ice is sheared from freezing surface by the iceremoval tools

ICESTA Auto lce Storage Room

1 .Mobile type, starting from 20 metric tons up to 100 metric tons

2.Robust steel used for the ice rake assembly and Ice Rake Hoist System

3.Reliable Sensors and Limit Switches to control the movement of Auto Ice Storage Room Automatically

4.Efficient Air cooler to keep the room temp down to -l0 degrees

5.100- 150 mm thickness Pancls keep the cold inside the room

ICESTA lce Discharge Auger and Delivery Auger

1.Robust design suitable for severe working conditions

2.Single and Dual Screw Design, with a designed delivery rate of 25-40T per Hour

3.Renowned Gearbox with Motor ensures the high quality of ICESTA Brand.

4.Single or Dual lce outlet for one or two ice outlet, which can deliverice at sametime to twin batch plants.

5.Stainless material or Galvanized Steel optional.

ICESTA Smart lce Dose System

1.Robust design suitable for severe working conditions

2.Ice Hopper volume up to 500KG

3.Renowned Gearbox with Motor ensures the high quality of ICESTA Brand:; 4.Accurate lce Scale system

5.Stainless material or Galvanized Steel optional.

ICESTA ICE/COLD WATER PLANT

Application Industry

More and more Coling or temp.Reduction industry used the ice machines to meet their higher technic request due to their deeper knowledge about this equpment.

Auxiliary Equipment

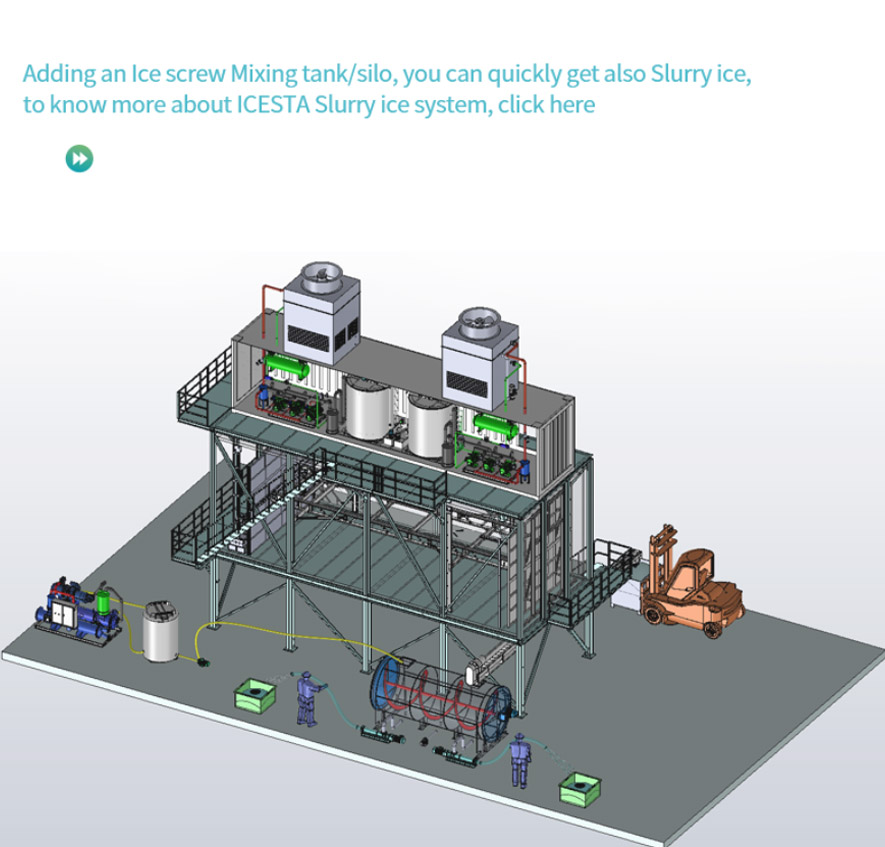

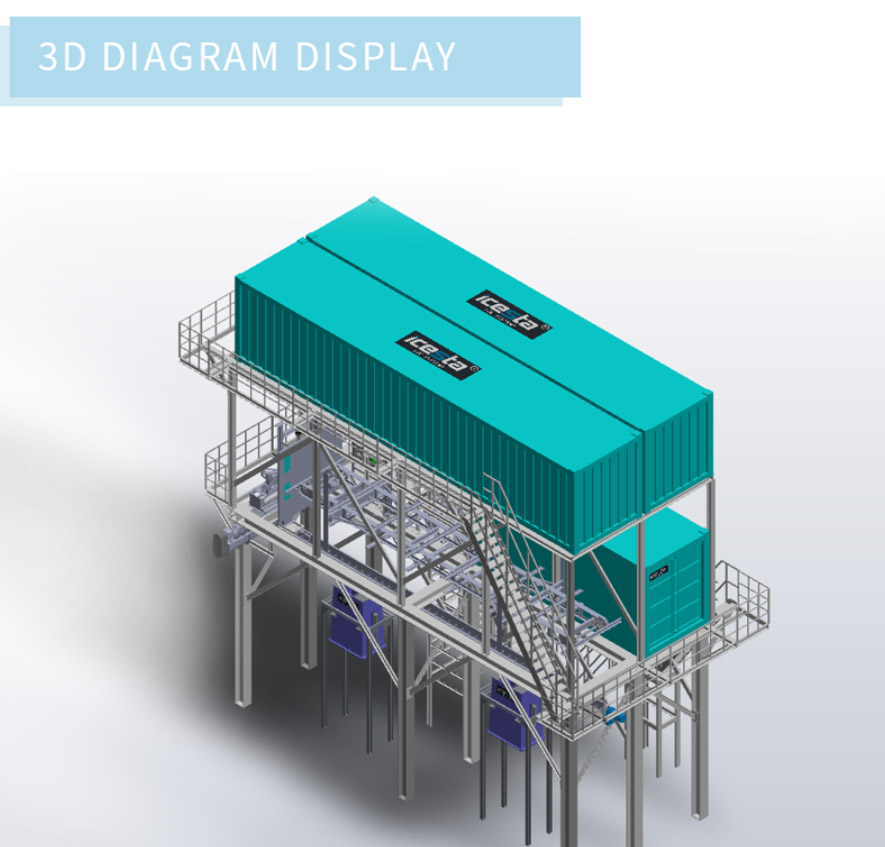

Fully automatic system "storage" and "ice delivery" integration project

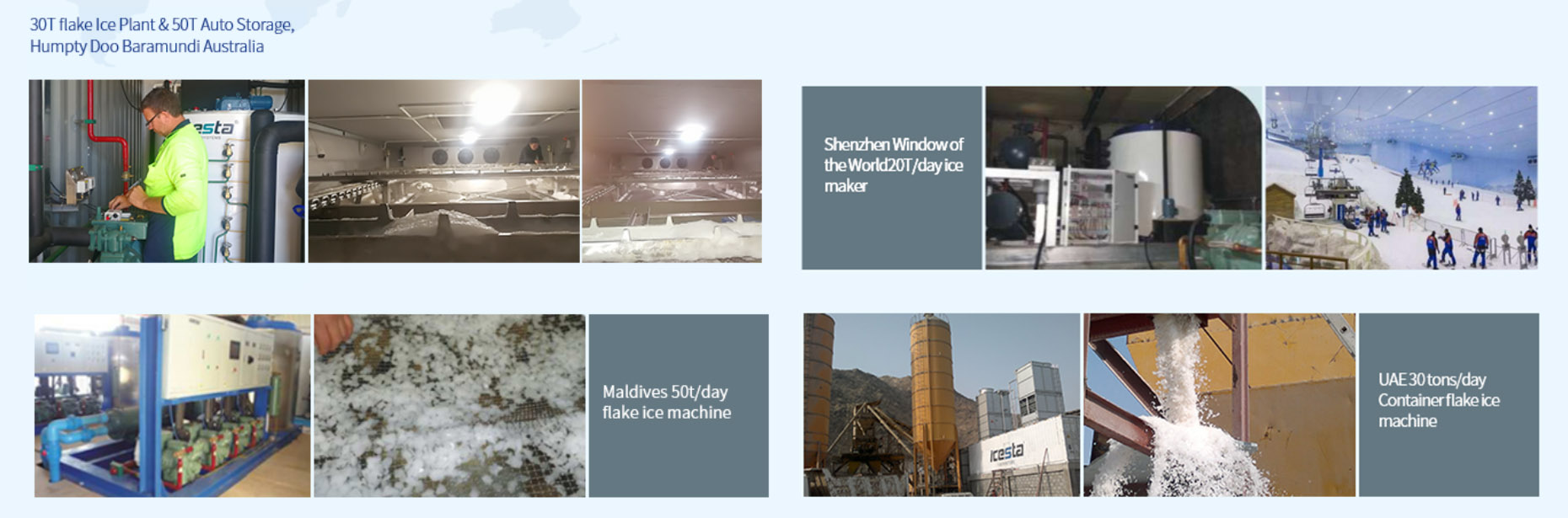

Engineering Case

Since 2007, ICESTA products have been sold to more than 80 countries around the world, and provide distributor services in many regions.

Picture Display

Technology, change the world, innovate, and subvert tradition. We are committed to making people's production and life more convenient, efficient and beautiful

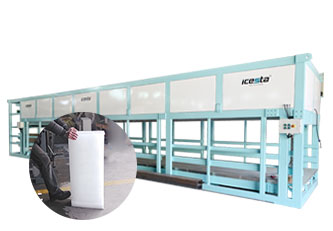

Product Hot Sale

Tube ice machine

Sea water ice slurry machine

Seawater flake ice machine

BBlock ice machine

Cube ice machine

All-in-one Automatic (Containerized) ice making & Storage& Delivery system

ICESTA

20 years dedication in ice making technology to create excellence.

Shenzhen Brother Ice Maker System Co., Ltd. (hereinafter referred to as ICESTA), as a well-known ice-making equipment manufacturer and industry pioneer, since its establishment in 2007, it is committed to providing excellent "Made in China". Technological innovation and forge ahead, continuous expansion of product lines, continuous upgrades of products, and annual expansion of the factory.

There are more than 150 people in Shenzhen and Dongguan R&D, manufacturing, and sales bases, as well as production, management, and domestic and overseas technical teams. The annual output value is up to More than 120 million yuan; two branch companies were established: Shenzhen Brother Cold Chain Technology Co., Ltd., Liaoning Sports Sports Technology Co., Ltd.; three major brands: including ICESTA series of flake ice machines, block ice machines, tube ice machines, and ice slurry Machines, ice pellet machines, integrated ice storage and delivery container ice making systems, consumer and commercial ice machines, Brother series snow blowers, snow machines, Snowtek series block ice machine chillers, etc., have covered all mainstream ice in the world today It also expands to the field of cold chain equipment, such as chillers, freezers, cold storage equipment, etc., and at the same time provides various medium and low temperature refrigeration units for global industrial and commercial refrigeration equipment and engineering companies, so as to provide users with the most convenient and comprehensive use Ice and refrigeration solutions.

ICESTA's branded ice making equipment, with daily output ranging from 25Kg to 100 tons, is widely used in supermarkets, catering hotels, aquatic products and meat processing, poultry slaughter, leather manufacturing, chemical dyes, concrete construction, ocean fishing, artificial ski resorts, etc. industry. So far, ICESTA has obtained more than 40 national new patents, and has passed the European Union CE safety standards and PED pressure vessel certification, American AMSE certification, ISO9001 quality management system certification, national high-tech enterprise certification, etc., serving more than 80 customers worldwide Countries and regions.

ICESTA Customers & Certificate

Packages & Service

Packages & Service