The ICESTA Parallel Rack Condensing Unit is a powerhouse in the world of ice machines, boasting energy-efficient operation that saves up to 15% in power consumption compared to single-unit compression units. Its fast cooling capabilities ensure that your warehouse's temperature is quickly brought to optimal levels, maximizing efficiency. With easy installation thanks to its integrated design, maintenance and management are a breeze, making it a must-have for any food industry business looking to improve cold room operations.

At ICESTA, we strive to serve our customers with top-of-the-line refrigeration solutions, such as the Parallel Rack Condensing Unit. Our focus on energy efficiency ensures that your operation runs smoothly while minimizing costs. With fast cooling capabilities, you can trust that your products will be stored at the optimal temperature. Our easy installation process means less downtime and more time focusing on your business. At ICESTA, we are dedicated to serving you with high-quality products that are reliable and efficient, allowing you to focus on what matters most - serving your customers.

At ICESTA, we serve our customers with cutting-edge technology and top-of-the-line products like the Parallel Rack Condensing Unit. Our energy-efficient design ensures lower operating costs and a reduced environmental impact. With fast cooling capabilities, your products will stay fresh and safe for longer periods. Our easy installation process saves you time and hassle, allowing you to start using your condensing unit quickly and efficiently. At ICESTA, we are committed to providing exceptional quality and performance, ensuring that your business runs smoothly and efficiently. Trust us to serve you with the best refrigeration solutions on the market.

Product Introduction

The Parallel Rack condensing unit produced by our company has the following characteristics:

1. Compared with a single-unit compression condensing unit, the initial investment of parallel units under the condition of the same warehouse cooling capacity can save about 10%;

2. The power consumption is less than that of a single-unit compression condensing unit under the same conditions, saving more than 15% of energy consumption;

3. The cooling speed is fast. Compared with the single-unit compression condensing unit with the same conditions, the parallel unit can quickly reduce the temperature of the warehouse when there is stock in the warehouse, and improve the utilization rate of the warehouse;

4. The unit is integrated, which is convenient for construction and installation, and convenient for centralized maintenance and management.

5. Each unit we manufacture is dried, vacuumed, leak picked and pressure tested to 2.4 MPa and filled with nitrogen to protect shipping and inspection. All electrical components are easy to maintain, adjust and service.

6. The unit is connected to all piping and lines at the factory ready for installation and use. Installation requires only connections to liquid and gas piping, control circuits, and main power lines to the air cooler and compression condensing unit.

Application Industry

ICESTA Industrial condensing unit is available for all kinds of Low temperature, Mid, and high temperature cold room,Quick Freezer rooms, which mainly apply for Food industry like cheese, seafood,meat, ,fruit jams,vegetable, etc and Cold chains,etc

Core Advantages

Advantages include increased capacity, redundancy, improved efficiency, enhanced control, and flexibility

1. Bitzer compressor

We use German Bitzer compressor ,you can easily acquire spare parts or after-sale service around the globe.

2.Auto Control System

The machine is using Siemens PLC and touch screen controller for system control.After very short learning,operator may get to handle the whole machine

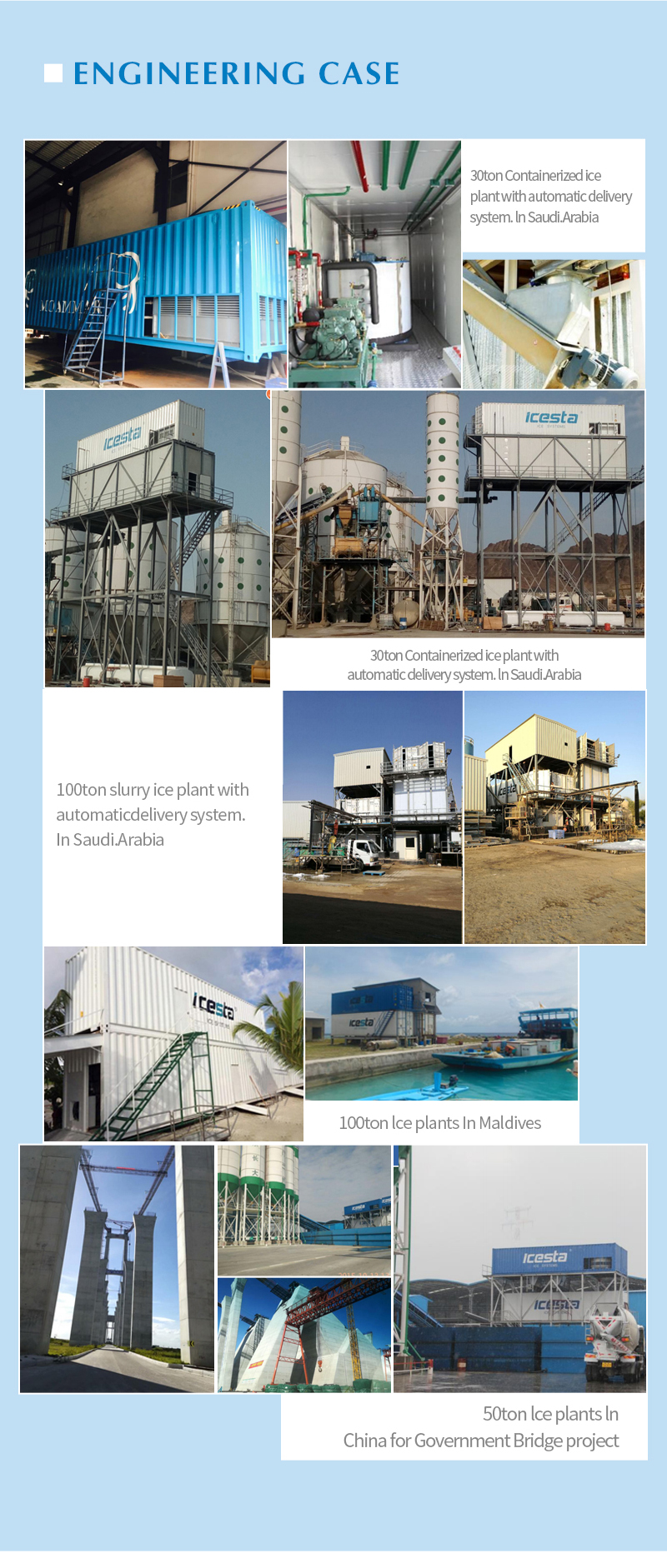

ENGINEERING CASE

Technical Parameters

Specification of Air Cooled Condensing Units

Advantages of Air cooled Condensing Unit

1. Easy to Install and maintain

2. High efficiency of Heat Exchange and Long Life Time

3.Compact Design & Reasonable Air Ventilation Design & Efficient Heat Transfer

4.Container Design with Small Footprint, and Long worn-out time of control system

Application Scope:

Fresh Keeping, Food Processing, Chemistry and Pharma, Refrigerationand Ice Making.Cold Store, Cold Storing Facilities, Agriculture

3D DIAGRAM DISPLAY

Picture Display

Product Hot Sale

ICESTA

20 years dedication in ice making technology to create excellence.

Shenzhen Brother Ice System Co., Ltd. ( ICESTA Brand), a well-known ice machine manufacturer and industry leader and pioneer in China.The product covers flake ice /Block ice machine, Tube ice /slurry ice/plate ice/cube ice machines, water

chillers,Plate/spiral/blast freezers, Automatic ice storing & delivery system with integrated container ice system,artificial snow making machine.etc

Experiences & History:

20-Years Team focus on innovative solution in Ice & Cooling technology.

16-Years Professional Manufacturer, Supplier of Excellent Turnkey ice & cooling projects.

Industry status& Reputation:

* TOP 3 of China industrial ice machine Brand with strong capability of R&D

* 20000㎡ Factory

* ISO 9001 , CE, PED, ASME (U.S ) Certificates etc

Technology & Management capability:

* 80+ patents Certificates

* High Technology enterprise Certificate

Services & Global Net:

* Export to 80+ countries

* Local service in 50+ countries with networks all over the world.

* 1-2 years warranty covers each component.

FAQ

FAQ (Frequently Asked Questions)

1. Questions before quotation

A. Would you make ice from seawater, saltwater or freshwater?

B. Where and when would the machine be installed roughly?The ambient temperature and water inlet temperature?

C. What’s the power supply?

D. What is the application of the flake ice produced?

E. Which cooling mode would you prefer to? Water or air ,Evaporative cooling?

2. Installation & commissioning

A. Installed by customers according to the manuals, online instructions and live video conference of ICESTA.

B. Installed by ICESTA engineers.

a. ICESTA would arrange 1~3 engineers based on the projects to the installation sites for the final supervision of all

installations and commissioning.

b. Customers need to provide local accommodation and round-trip ticket for our engineers and pay for the commissions. US Dollars 100 per engineer per day.

c. Power, water, installation tools and spare parts need to be ready before ICESTA engineers arrive.

3. Warranty & Technical support

A. 1 year after Bill of Lading date.

B. Any failure occurred within the period due to our responsibility, ICESTA will supply the spare parts for free.

C.ICESTA provide full technical support and training courses after equipment installation and commissioning.

C. Permanent technical support & consultation all life long for the machines.

D. Over 25 engineers for instant after-sale services and more than 15 are available for serving overseas.

365 days X 7 X 24 hours phone / EMAIL assistance

4. Failure Claim procedures

a. Detailed written failure description is required by fax or by mail, indicating the relevant equipment information and detailed description of failure.

b. Relevant pictures are required for failure confirmation.

c. ICESTA engineering and after-sales service team will check and form a diagnosis report.

d. Further trouble-shooting solutions will be offered to customers within 24 hours after receiving the written description and pictures