The industrial tube ice maker from ICESTA is manufactured with high-quality stainless steel, ensuring durability and cleanliness in ice production. With a capacity ranging from 1 to 100 tons per day, this tube ice maker is designed for high ice output, reliable performance, and a humanized design. The innovative design features a smooth ice stripping surface, optimized driving structural design, and a patented H-M interactive intelligent control system with a touch-screen, making it a top choice in the ice-making industry.

At our company, we serve our customers with the finest quality industrial tube ice makers made from high-quality stainless steel. With a capacity ranging from 1 to 100 tons per day, our ice makers are built to withstand heavy-duty use in industrial settings. Our commitment to excellence means that our ice makers are not only durable and reliable, but also efficient and cost-effective. We pride ourselves on providing top-notch customer service and support, ensuring that our customers have a seamless experience from purchase to installation and beyond. Trust us to serve you with the best in industrial ice making technology.

At our company, we serve our customers with the highest quality industrial tube ice maker made of stainless steel. Our product ranges from 1 to 100 tons per day, ensuring we meet the diverse needs of our clients. We take pride in delivering products that are reliable, durable, and efficient, guaranteeing optimal performance and satisfaction. With our commitment to excellence and customer satisfaction, we strive to provide top-notch service and support to ensure a seamless experience for our customers. Choose our industrial tube ice maker and let us serve you with the best in quality and performance.

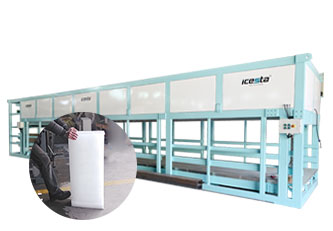

Product Introduction

ICESTA is providing the world Excellent Tube ice solutions with high ice output, reliable performance and humanization design.

Tube ice is in the shape of crystal and powderless tubes. Comprared with flake ice, the melting time of tube ice is longer, and it is more suitable for cooling in an unisulated environment. Tube ice is comparatively solid and less prone to ice lumps, so it is more suitable for long distance delivery.

Application Industry

ICESTA is providing the world Excellent Tube ice solutions with high ice output, reliable performance and humanization design.

Technical Parameters

* The technical data based on 30°Cambient temp.20°Cwater inlet temp.

* The evaporating / condensing temp.:-15C/40°C(Air-coole) 38°C(Water cooled)

* Power supply: 3P/380V/50HZ(3P/220/60HZ,3P/380V/60HZ,3P/460V/60HZ Optional)

* Refrigerant: R404A(R22 R17 R507 is optional)

* Ice tube diameter: Φ22,Φ29,Φ35,Φ42 is optional

1t,2t,3t,5t/24h

Show Details

All great works are moving in countless details, and every high-quality ice machine is precisely carved out of the details.

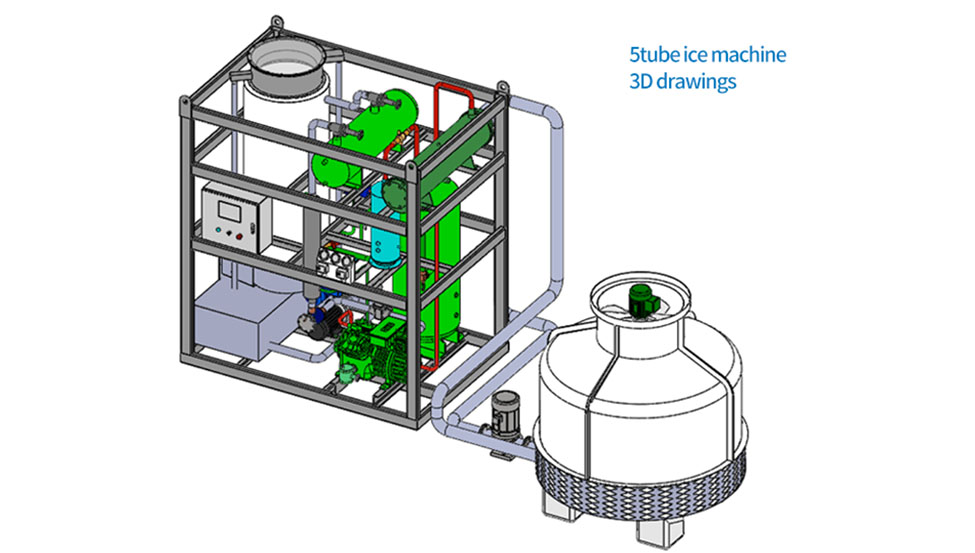

Drawing Display

The ICESTA team has used more than 20 years of experience in refrigeration and ice making to continuously innovate products to achieve higher efficiency, more stable operation, smoother ice removal and ice production.

Advantage

ADVANTAGES OF ICESTA TUBE ICE PLANTINNOVATIVE DESIGN FOR GENERATOR

1. Innovative manufacturing artwork has been adopted.The lce stripping surface is smooth as a mirror. That has tremendouslyincreased ice stripping efficiency and energy-efficiency ratio.

2. The ice cutter can be easily dismantled and replaced as a whole.

3. Compared with peers,ICESTA evaporator can form even water membrane more effectively.That makes more even and crystal ice tubes

4. The upper and lower freezing water reservoir is openly structured, which helps a lot withcleaning and disinfection.

5. ICESTA ice plant adopts an optimized driving structural design, which ensures both simplestructure and high reliability.

6. ICESTA customizes a reasonable design of ice plant suitable for convenient containertransportation for oversea clients.

7. Deice just need 130-200s.

PATENTED H-M INTERACTIVE INTELLIGENTCONTROL SYSTEM WITH TOUCH-SCREEN:

1.The working status of the ice system display alive in screen.

2.Setting stop-time at will.

3. All possible failure and trouble-shooting is programmed in.

4.Local time could be set.

3D diagram display of tube ice machine and office building layout plan

Picture Display

Technology, change the world, innovate, and subvert tradition. We are committed to making people's production and life more convenient, efficient and beautiful.

Auxiliary Equipment

Optimal industrial application: lce packing

Components:

1.Buffer Storage Bin (ranging from 50OKG to 2000KG)

2.Built-in delivery screw

2.Built-in delivery screw

3.Dual control system (Manual and foot pedal); Foot pedal can start and stop at will, which is nearly a semi automatic packing machine.

PACKAGE UNIT OF TUBE ICE MAKING, DELIVERING, PACKING,ICE BAGS CONVEYING.

Customer-Oriented design.Our consideration and,innovation reach everywhere.

Engineering Case

30ton ice tube machine with ice dispenser (semi-automatic ice packing machine.)/ Philippines.

Since 2007, ICESTA products have been sold to more than 80 countries around the world, and provide distributor services in many regions.

Product Hot Sale

Flake ice machine

Ice delivery system

Ice slurry machine

Block ice machine

Cube ice machine

All-in-one Automatic (Containerized) ice making & Storage& Delivery system

ICESTA

20 years dedication in ice making technology to create excellence.

Shenzhen Brother Ice Maker System Co., Ltd. (hereinafter referred to as ICESTA), as a well-known ice-making equipment manufacturer and industry pioneer, since its establishment in 2007, it is committed to providing excellent "Made in China". Technological innovation and forge ahead, continuous expansion of product lines, continuous upgrades of products, and annual expansion of the factory.

There are more than 150 people in Shenzhen and Dongguan R&D, manufacturing, and sales bases, as well as production, management, and domestic and overseas technical teams. The annual output value is up to More than 120 million yuan; two branch companies were established: Shenzhen Brother Cold Chain Technology Co., Ltd., Liaoning Sports Sports Technology Co., Ltd.; three major brands: including ICESTA series of flake ice machines, block ice machines, tube ice machines, and ice slurry Machines, ice pellet machines, integrated ice storage and delivery container ice making systems, consumer and commercial ice machines, Brother series snow blowers, snow machines, Snowtek series block ice machine chillers, etc., have covered all mainstream ice in the world today It also expands to the field of cold chain equipment, such as chillers, freezers, cold storage equipment, etc., and at the same time provides various medium and low temperature refrigeration units for global industrial and commercial refrigeration equipment and engineering companies, so as to provide users with the most convenient and comprehensive use Ice and refrigeration solutions.

ICESTA's branded ice making equipment, with daily output ranging from 25Kg to 100 tons, is widely used in supermarkets, catering hotels, aquatic products and meat processing, poultry slaughter, leather manufacturing, chemical dyes, concrete construction, ocean fishing, artificial ski resorts, etc. industry. So far, ICESTA has obtained more than 40 national new patents, and has passed the European Union CE safety standards and PED pressure vessel certification, American AMSE certification, ISO9001 quality management system certification, national high-tech enterprise certification, etc., serving more than 80 customers worldwide Countries and regions.

Engineering Case

ICESTA Customers & Certificate

Packages & Service

Packages & Service

FAQ

1.Questions before quotation

A. Would you make ice from seawater, saltwater or freshwater?B. Where and when would the machine be installed roughly?The ambient temperature and water inlet temperature?C. What’s the power supply?D. What is the application of the flake ice produced?E. Which cooling mode would you prefer to? Water or air ,Evaporative cooling?

2.Installation & commissioning

A. Installed by customers according to the manuals, online instructions and live video conference of ICESTA.B. Installed by ICESTA engineers.a. ICESTA would arrange 1~3 engineers based on the projects to the installation sites for the final supervision of all installations and commissioning.b. Customers need to provide local accommodation and round-trip ticket for our engineers and pay for the commissions. US Dollars 100 per engineer per day.c. Power, water, installation tools and spare parts need to be ready before ICESTA engineers arrive.

3.Failure Claim procedures

a. Detailed written failure description is required by fax or by mail, indicating the relevant equipment information and detailed description of failure.b. Relevant pictures are required for failure confirmation.c. ICESTA engineering and after-sales service team will check and form a diagnosis report.d. Further trouble-shooting solutions will be offered to customers within 24 hours after receiving the written description and pictures

Advantages

1.Over 25 engineers for instant after-sale services and more than 15 are available for serving overseas.365 days X 7 X 24 hours phone / EMAIL assistance

2.Permanent technical support & consultation all life long for the machines.

3.ICESTA provide full technical support and training courses after equipment installation and commissioning.

4.Any failure occurred within the period due to our responsibility, ICESTA will supply the spare parts for free.

About Brother Ice System

Shenzhen Brother Ice Systems Co., Ltd. is (ICESTA for short) located in Shenzhen of China. Our company is a professional manufacturer and exporter specializing in designing and supplying innovative ice solutions worldwide with our own ICESTA ice machines.With a senior professional refrigerating team, modern operating conception, ordered efficient management model, and global strategy, ICESTA has founded a substantial base to tend towards the global market, then play an important role in the fresh keeping and cooling in the field of aquatic food & meat processing, ocean-going fishing, fowl slaughtering, concrete construction project, large supermarket and chain stores, dye chemical industry, mining and medical facilities.In line with our customer-oriented philosophy, ICESTA management is actively aligning the business structure to well meet customers' needs with a wide range of products, excellent quality as well as credible service. As a professional exporter, ICESTA will strive to create maximum value for our esteemed clients.