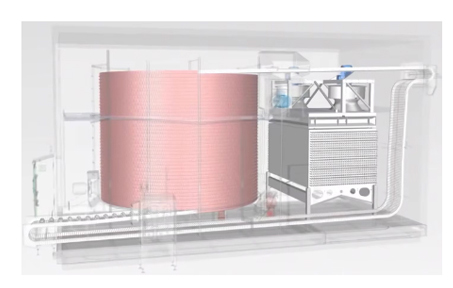

The self-stacking spiral freezer with a hygienic design offers up to 50% more freezing output compared to traditional models. Its self-stacking belt eliminates the need for belt rails, making the conveyors almost 100% accessible for easy cleaning. Featuring an innovative ADF system, automatic cleaning options, and a fully welded floor, this commercial ice maker ensures optimal performance, higher efficiency, and extended equipment life.

At our core, we serve efficiency and productivity with our Self-Stacking Spiral Freezer. With a 50% increase in output capacity, your business can streamline operations and meet growing demands with ease. Our innovative design not only maximizes production but also prioritizes hygiene, ensuring food safety and quality every step of the way. We serve reliability and peace of mind, knowing that our freezer will consistently deliver exceptional results. Trust in our commitment to serving your needs, so you can focus on what matters most – serving your customers. Choose our Self-Stacking Spiral Freezer and experience the difference we can make for your business.

At our company, we serve by providing top-of-the-line self-stacking spiral freezers that offer 50% more output capacity and a hygienic design. Our products are designed with efficiency and cleanliness in mind, allowing our customers to streamline their production processes and maintain the highest quality standards. With our self-stacking spiral freezers, businesses can increase their output while ensuring that their products are stored and preserved in the most sanitary conditions possible. We are dedicated to serving our customers by delivering reliable and innovative solutions that help them succeed in their operations.

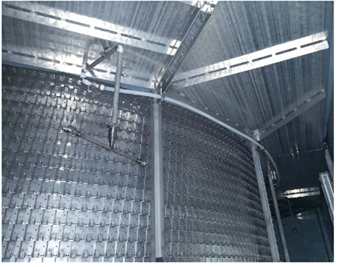

The self-stacking spiral freezer is a compact and hygienic freezer design. Compared to the traditional low tension spiral freezer, the self-stacking spiral freezer eliminates the rails supporting the belt, that means up to 50% more freezing output with the same foot print.The conveyors are almost 100% accessible to cleaning thanks the elimination of the belt rail and drum, The freezer has combined the state-of-the-art clean-in-place (ClP) system. An open, easily cleanable and accessible design optimizes sanitation standards and decreases system downtime for cleaning and maintenance. This feature reduces contamination and extends the life of the equipment by preventing waste buildup and simplifying the cleaning process.

Technical Date

Structure | Self-stacking spiral freezer |

| Drum Diameter | S4, S6, S7, S9, S10 |

| Layers | 6~50 |

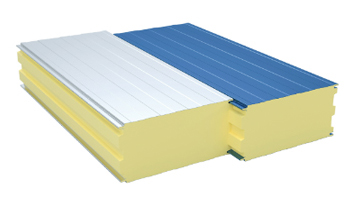

| Insulated Enclosure | PIR/PU,SS skin at both sides, fully welded |

| Mesh Belt Width | 420~1370mm |

| Infeed length | 700mm |

| Outfeed length | 600mm |

| Control panel | PLC touch screen, SS panel |

| Refrigerant | Freon, Ammonia, CO₂ |

| Evaporator | Al/SS tube, aluminum fin, variable fin pitch |

| Defrost | Water/hot gas/ADF optional |

| Freezing\cooling time | Stepless variable frequency adjustable |

| Cleaning | Manual\ Belt Washer\ ClP |

| Freezing capacity | 300 to 5000kg/h |

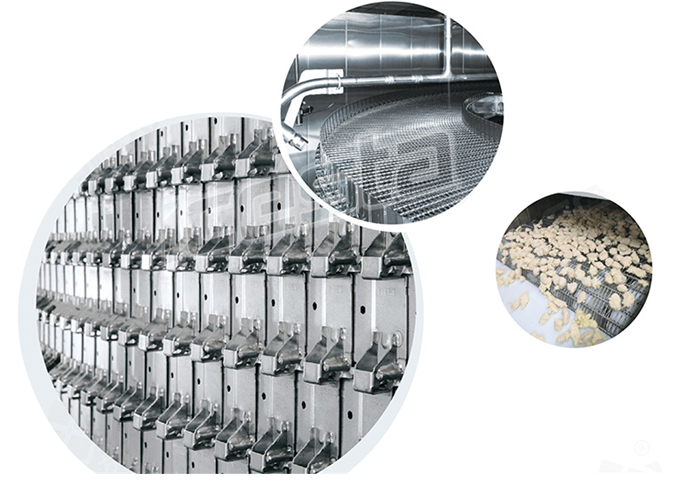

Self-Stacking Belt

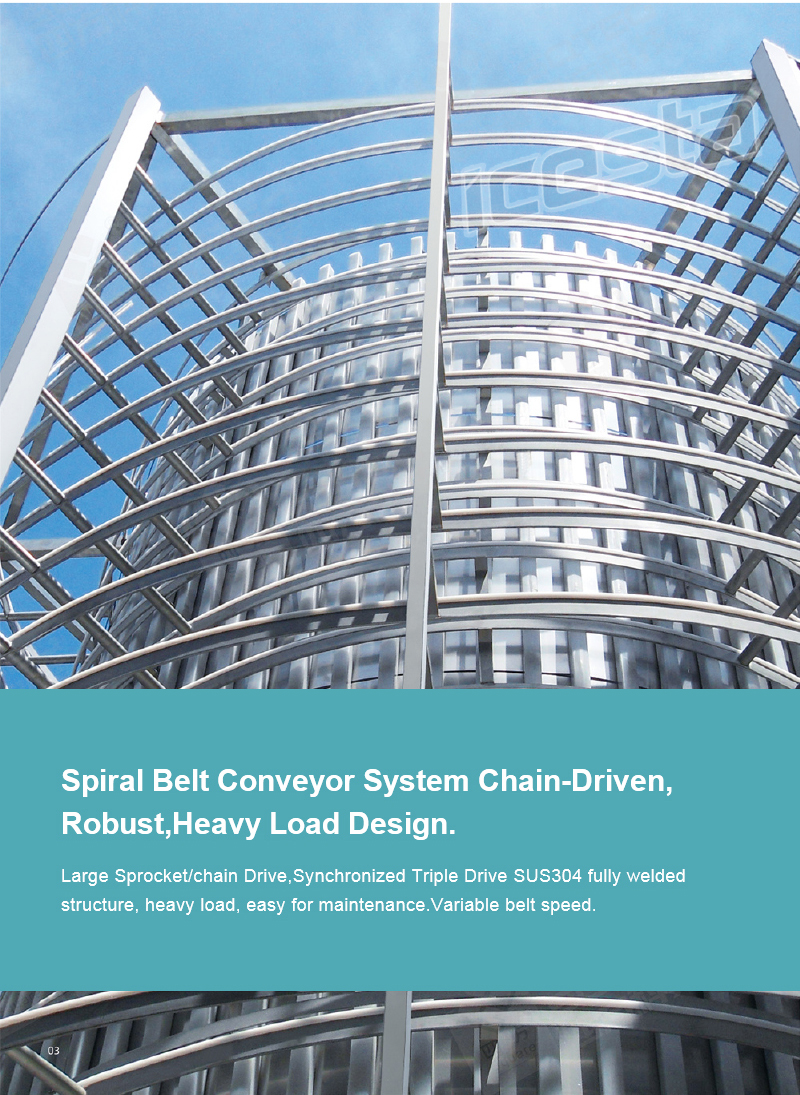

The self-stacking belt is driven by chain system, operates completely on rolling balls. The resistance and noise caused by running chain is reduced, so smaller motors can drive the system. The belt is not in tension in run. The belt is less likely to be stretched and deformed. Self-stacking belt stacks on the top of each other’s side links. This self-stacking feature eliminates the rails supporting the belt.

Self-contained Freezing Zone

The special holes on the side links also introduce cold air into product zone and create turbulence.This provides uniform product temperature across the belt and increases the heat exchanging efficiency

Automatic Cleaning Systems

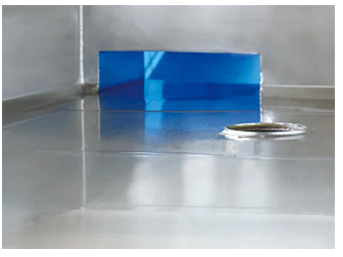

Fully welded floor

Insulated Enclosure

Intelligent Control System

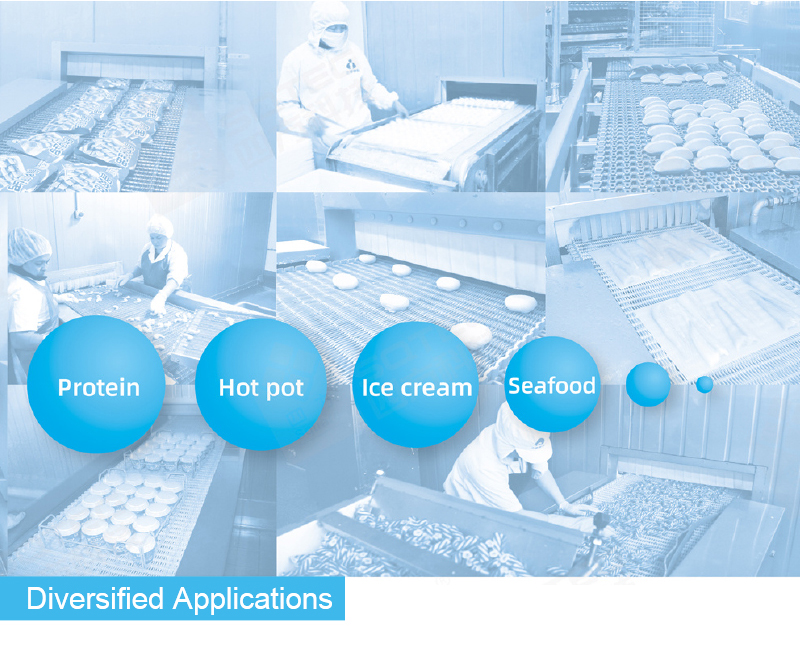

Product Hot Sale

20 years focus on innovative solution in ice making and cooling technology

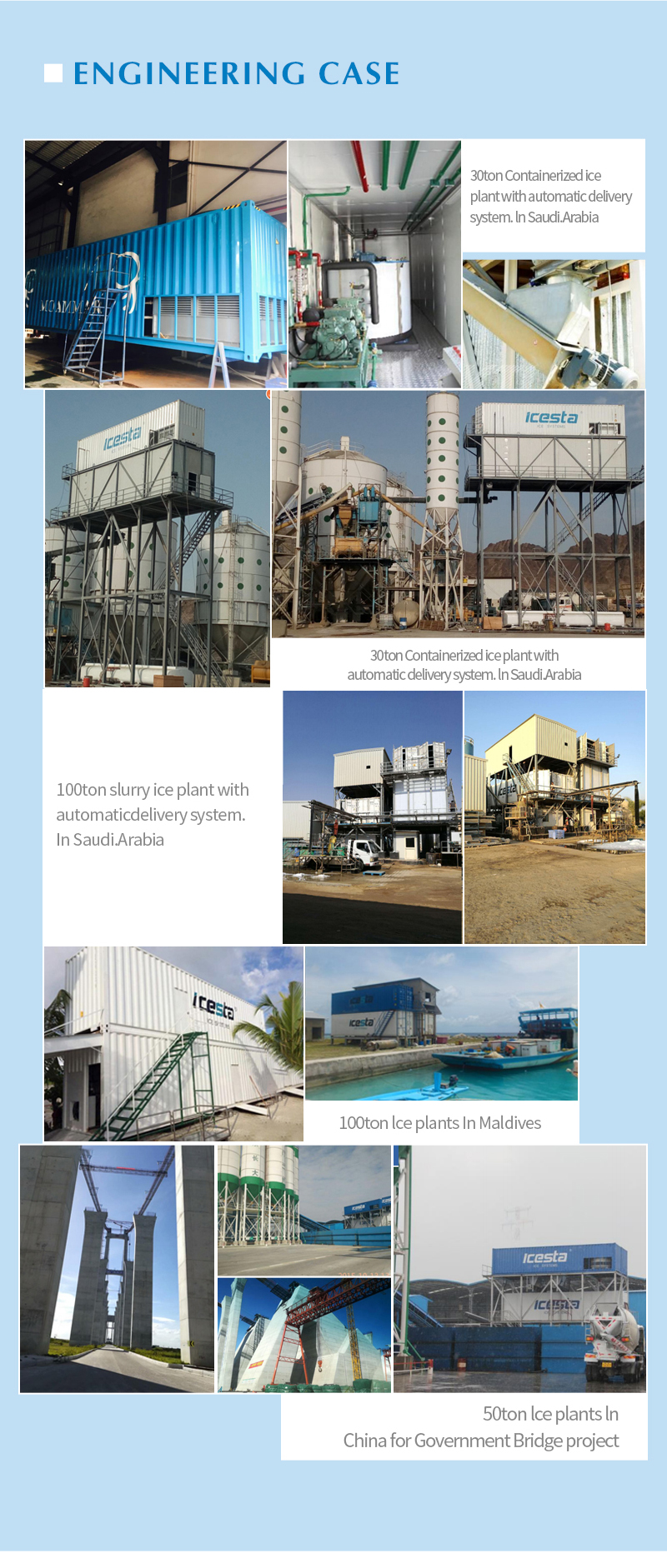

Shenzhen Brother Ice System Co., Ltd. ( ICESTA Brand), a well-known ice machine manufacturer and industry leader and pioneer in China.The product covers flake ice /Block ice machine, Tube ice /slurry ice/plate ice/cube ice machines, water chillers,Plate/spiral/blast freezers, Automatic ice storing & delivery system with integrated container ice system,artificial snow making machine.etc

* Experiences & History:

Dscades of Team focus on innovative solution in lce & Cooling technology.

Decadal Professional Manufacturer, Supplier of Excellent Tumkey ice & cooling projeds.

* Indlustry status& Reputation

Top lce Machine Brand in China.

20000 ㎡ Factory

ISO 9001 ,CE, PED,ASME (U.S ) Certifcates etc

* Technology& Management capability:

80+ patents

High Technology enterprise Certifcate

* Services & Global Net

Export to 80+ countries

Local service in 50+ countres with networks all over the world

1-2 years waranty covers each component.

In China, ordinary working time is 40 hours for employees who work full time. In Shenzhen Brother Ice System Co., Ltd, most employees work abiding by this kind of rule. During their duty time, each of them devotes their full concentration to their work so as to provide customers with the highest-quality Tube Ice Machine and an unforgettable experience of partnering with us.

Yes, if asked, we will supply relevant technical details regarding ICESTA Ice System. Basic facts about the products, such as their primary materials, specs, forms, and primary functions, are readily available on our official website.

Regarding the attributes and functionality of the commercial ice maker, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

Shenzhen Brother Ice System Co., Ltd always considers communicating through phone calls or video chat the most time-saving yet convenient way, so we welcome your call for asking for the detailed factory address. Or we've displayed our e-mail address on the website, you are free to write an E-mail to us about the factory address.

To draw in more users and consumers, industry innovators are continually developing its qualities for a larger range of application scenarios. Additionally, it can be customized for clients and has a reasonable design, all of which help grow the customer base and loyalty.

The application of the QC process is crucial for the quality of the final product, and every organization needs a strong QC department. commercial ice maker QC department is committed to continual quality improvement and focuses on ISO Standards and quality assurance procedures. In these circumstances, the procedure may go more easily, effectively, and precisely. Our excellent certification ratio is a result of their dedication.