Turn-key Concrete Cooling Solution

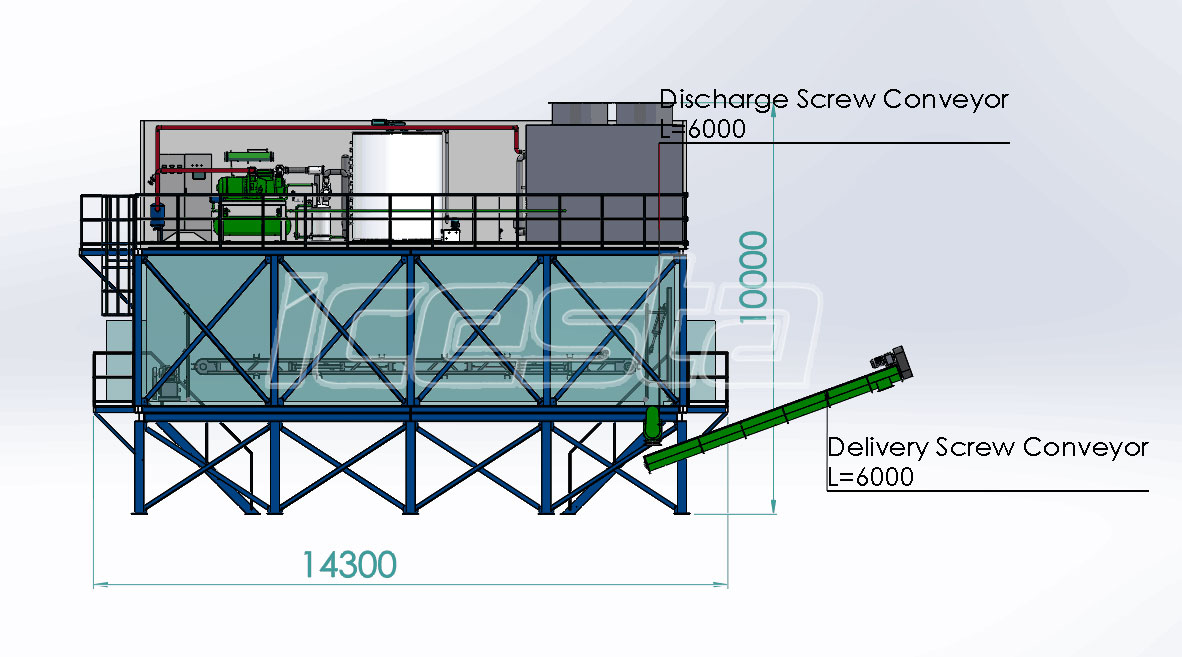

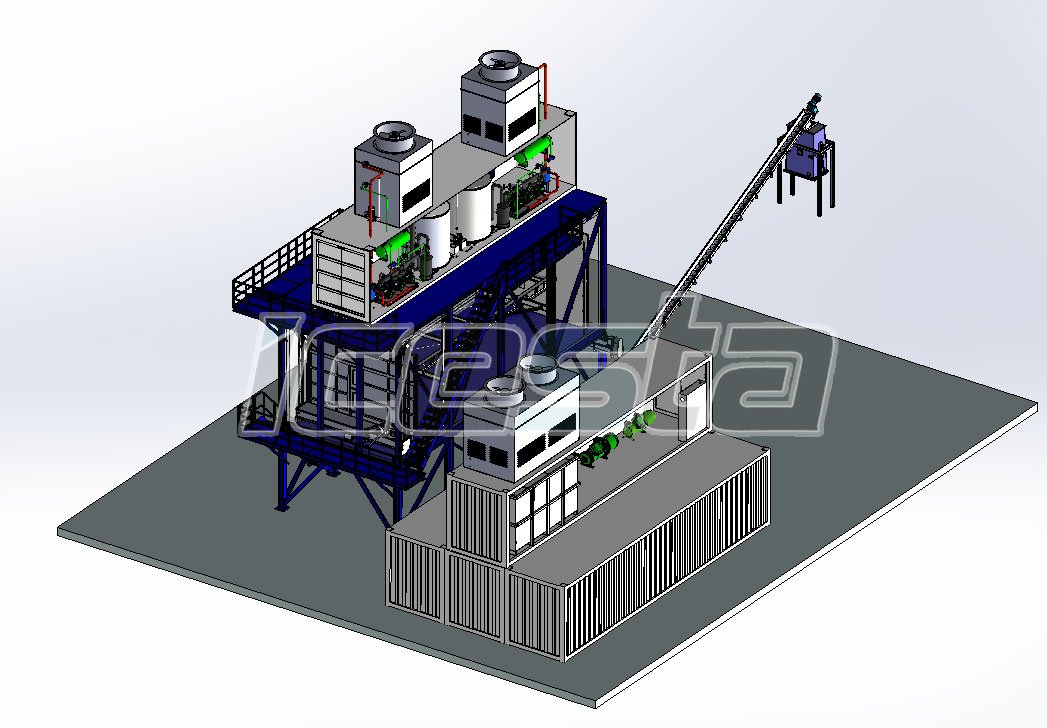

Complete Set of Containerzied Ice Water Plant

& Ice Plant & Ice Storing & Dosing Syst

Over the past 15 years, ICESTA's strong R&D and engineering teams have continuously provided global customers with first-class customized ice solutions and complete turnkey projects.

Communication before design:

ICESTA’s Large Ice Solution have a very rigorous design process and PMP.(Project Management Procedure)

The following important communication must be made before the scheme design :

Application products/industries: such as fish, shrimp, meat products, or bread, ice cream, chemical pigments, concrete, ski resorts, etc.

Site environment: use area (national area, climate), workshop size, installation environment (open air, outdoor, seaside), water quality (salinity, etc.), water source (abundant or scarce water source, groundwater, or tap water, seawater, etc.), Ambient temperature (maximum air temperature, minimum air temperature), air salinity, water temperature, wet bulb temperature, etc., use the distance between the freezing point and the ice building

Requirements for use: 24-hour ice making capacity, maximum ice storage capacity, maximum ice delivery capacity, daily ice usage time etc.

Technical requirements:

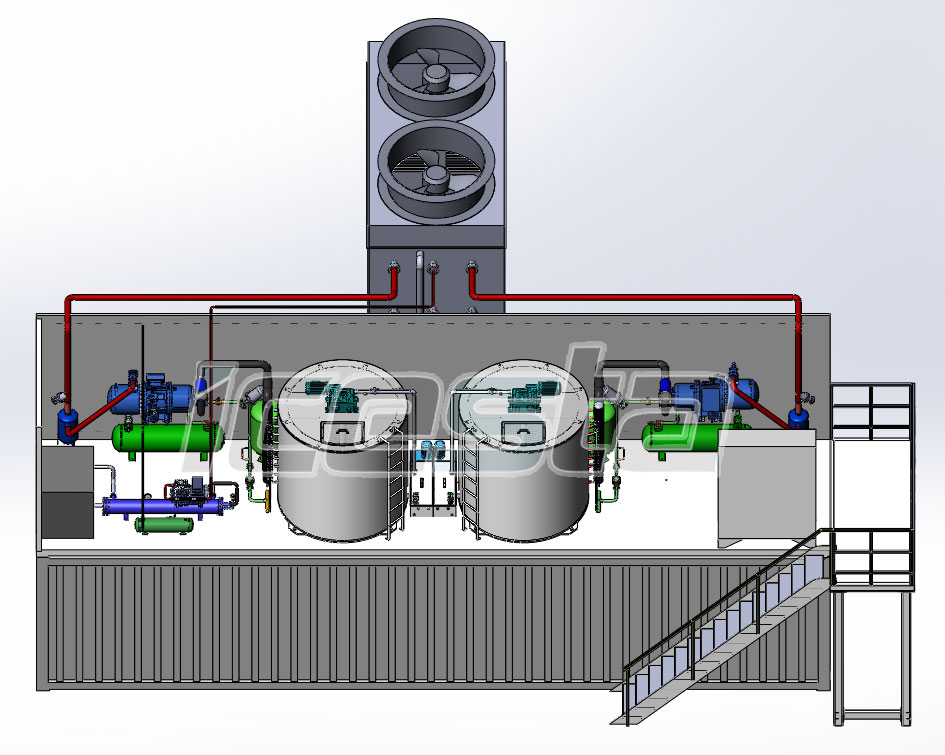

1 Cooling method (air cooling, water cooling, evaporative cooling)

2 Voltage requirements (pay special attention to special voltages: 220V 3P 60HZ, 440V 3P 60HZ, 380V 3P 60HZ

3 Materials, brands of important components such as compressors, whether a generator is required etc., need to do specific analysis for specific products.

I. Why Ice is needed for concrete Production

Over one decade, ICESTA has pioneered the field of concrete cooling technologies and continues to be the world class in concrete cooling, thanks to the continuous technological developments.

It is necessary to cool or heat the concrete to control the temperature of the freshly mixed and poured concrete. Without a controlled cooling, stress cracks could appear within the concrete, which causes instability and fractures. Especially in dam, tunnel or bridge projects this would be an incalculable risk.

For this reason, regulations about the concrete pouring temperature are being formulated more precise since ever, so that even in moderate temperature zones, the issue of “temperature-controlled concrete” is becoming increasingly important.

II. What constitutes ICESTA concrete cooling equipment

1. Container Ice Plant (Flake and Plate)

2. Ice Storage Facility

3. The Screw Conveyor

4. Ice Weighing Hopper Unit (Ice Dosing System)

III. Solution Design & Parts Description

After the customer’s demand confirmed,our technical team design the detailed project.

1. (Containerized)Flake ice machine

According to customer’s requirements, We supply

1) Standard Flake ice machine without container

2) Flake ice machine fitting in container (20FT, or 40HQ container). The ice machines are well fully pipe connected and tested fully before delivery from factory which give the user’s most convenience at site.

2*30tons per day evaporating cooling flake ice machines

Icesta ice factory, integrated with a Vivid H-M Interactive Feature, cools your Concrete ready mix all automatically

* The Ice delivery system include:

A.Ice deflector & elevator system

The system consists of ice deflector, link mechanism ,support frame, driving unit, and Ice deflector open or closed by Hydraulic unit. one pair of up & down limit switch attached on the ice deflector, which will control the deflector on the up limit position or down,

B. Ice raker

During the ice flaker running, ice raker reverse to turn over the ice mound, which makes those dropping ice spread over the ice storage bin and the ice elevator which fixed with up and down limit as well as safety protection switch will automatically adjust the raker vertical height.

.

C.The screw conveyor under the ice storage

The screw conveyor below the ice deflector take charge of the ice which raked

Out from bin delivering to the outside, then into slant delivery system

D.Ice rake hoist

The ice raker elevator raise and reduce the ice raker by fixed pulley and steel wire rope, it consists of machine frame, drive gearing device, chain wheel, chain, steel wire rope and pulley. With the steel wire rope dragged by chain, the ice raker rise & down. and one pair of limit switch attached on the steel frame, which will control the raker stop on the up limit position or down limit position.

The Automatic Ice Storing Bin is converted from a (second hand)40FT Reefer Container (5-8 years). A reefer container is insulated in an integrated way. The temp controlling & defrosting system is controlled by ICESTA control system. And refrigeration Unit System is normally from Carrier or Mitsubishi.

Project references:

2*30ton flake ice plant +25ton Ice storage +10ton Chiller

for Concrete Cooling project (Bridge.Government project)

2*30ton Stainless steel flake ice machine +40FT freezer container with 304SUS Ice delivery system .Chile, Ice distribution Factory

2*20ton flake ice machine +40FT freezer container In Jiangsu ![]()

2*30ton flake ice machine +60T Storage in Dubai

2*60ton flake ice machine +60T Storage in Saudi Arabia