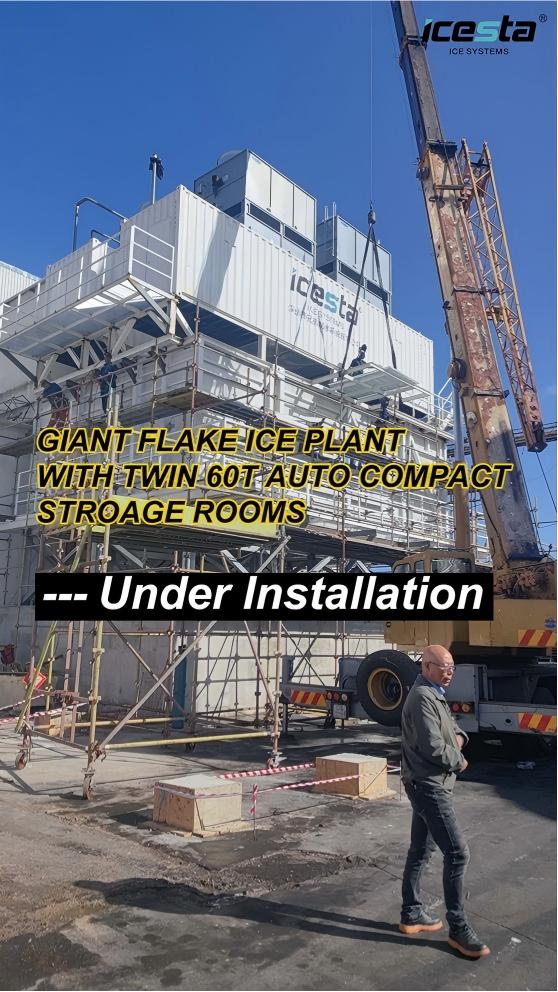

We are pleased to announce a major milestone in our customized integrated ice system project for our partner in South Africa. The core equipment—including a 160-ton-per-day ice maker, an 80-ton automated ice store, and a 312-ton chiller—is now in place. Our specialized team is currently carrying out the crucial phase of system integration and installation. This marks a significant step as this key project, designed to upgrade the regional seafood industry chain, steadily becomes a reality. We look forward to its commissioning, which will provide robust support for our client’s offshore fishing and deep-processing operations.

We are pleased to announce that the customized integrated industrial ice system for our key partner in South Africa has achieved a significant milestone. All major components are now in place, and the project has progressed into the crucial phase of system integration and installation.

The installation, led by our core team of engineers, is proceeding as planned. The central equipment we provided for this project—including a 160-ton-per-day high-performance flake ice maker, an 80-ton fully automated compact ice storage unit, and a 312-ton process chiller plant—has been delivered and positioned on-site. Our current focus is on the meticulous work of interconnecting piping, electrical configuration, and the integration of the intelligent control hub to ensure the entire system is primed for subsequent commissioning.

“This phase is about delivering on our promise and demonstrating our capability,” said our project manager on-site. “Our team is working closely with our partner to ensure every installation detail meets the highest engineering standards. Our goal is not just to deliver equipment, but to deliver a ‘power core’ that will operate with high efficiency and reliability, fueling our client’s business expansion.”

The system is tailor-made for the client’s offshore fishing and deep-processing operations. Upon full commissioning, it will significantly enhance their end-to-end cold chain capability. We look forward to soon commissioning this system together with our client, providing robust support for the immediate preservation, efficient processing, and stable export quality of their seafood products.