ICESTA's Direct Cooling Block Ice Machine is a high-performance industrial ice-making solution engineered for reliability and efficiency in demanding environments. Our machines produce dense, long-lasting block ice ideal for critical applications like fishery cold chains, concrete cooling, and food processing. The system delivered to Yemen—configured with a combination of 30T and 15T units to achieve 120-ton daily output—showcases our capability for large-scale, customized turnkey projects. Featuring premium components like Bitzer compressors, and intelligent PLC control, our equipment ensures stable, energy-efficient operation even in extreme high-temperature climates. We don't just sell machines; we provide complete, dependable ice production solutions that form the backbone of industries worldwide, ensuring product preservation and supporting economic development.

* Client:

Yemen Arab Investment Group

* Location:

Hodeidah, Yemen

* Industry:

Fisheries Cold Chain, Integrated Commerce

* Challenge:

Stable ice production in high-temperature environments, meeting large-scale fisheries preservation demand, ensuring long-term reliable equipment operation.

* Solution:

Customized 120T/Day Direct Cooling Block Ice System (3x30T + 2x15T hosts, including ice crushing equipment)

* Year: 2023

* Project Background & Challenge:

Hodeidah, Yemen, a crucial fishing port on the Red Sea coast, relies heavily on a stable and voluminous ice supply to ensure the freshness of seafood. However, the local climate is characterized by year-round high temperatures and aridity, with average temperatures often exceeding 30°C, posing extreme challenges to the cooling efficiency and continuous operation of ice-making equipment. Furthermore, traditional ice-making methods or small-scale units cannot meet the concentrated, large-scale ice demand driven by modern fishing and trade activities. The client, Yemen Arab Investment Group, required a turnkey solution capable of efficient, all-weather operation, easy maintenance, and producing high-quality ice to establish a regional ice supply core.

* ICESTA's Customized Solution:

Addressing Hodeidah's unique environment and client needs, ICESTA provided a tailored turnkey solution. The project centers on five direct cooling block ice machines. The combination of "three ICESTA-30T units + two ICESTA-15T units" achieves a total daily output of 120 tons, allowing flexible start-stop of units based on actual demand for optimized energy use.

1) Robust Core Components: All host machines utilize world-renowned Bitzer compressors and high-performance pressure vessels, ensuring powerful cooling capacity and extended service life even under high-temperature working conditions.

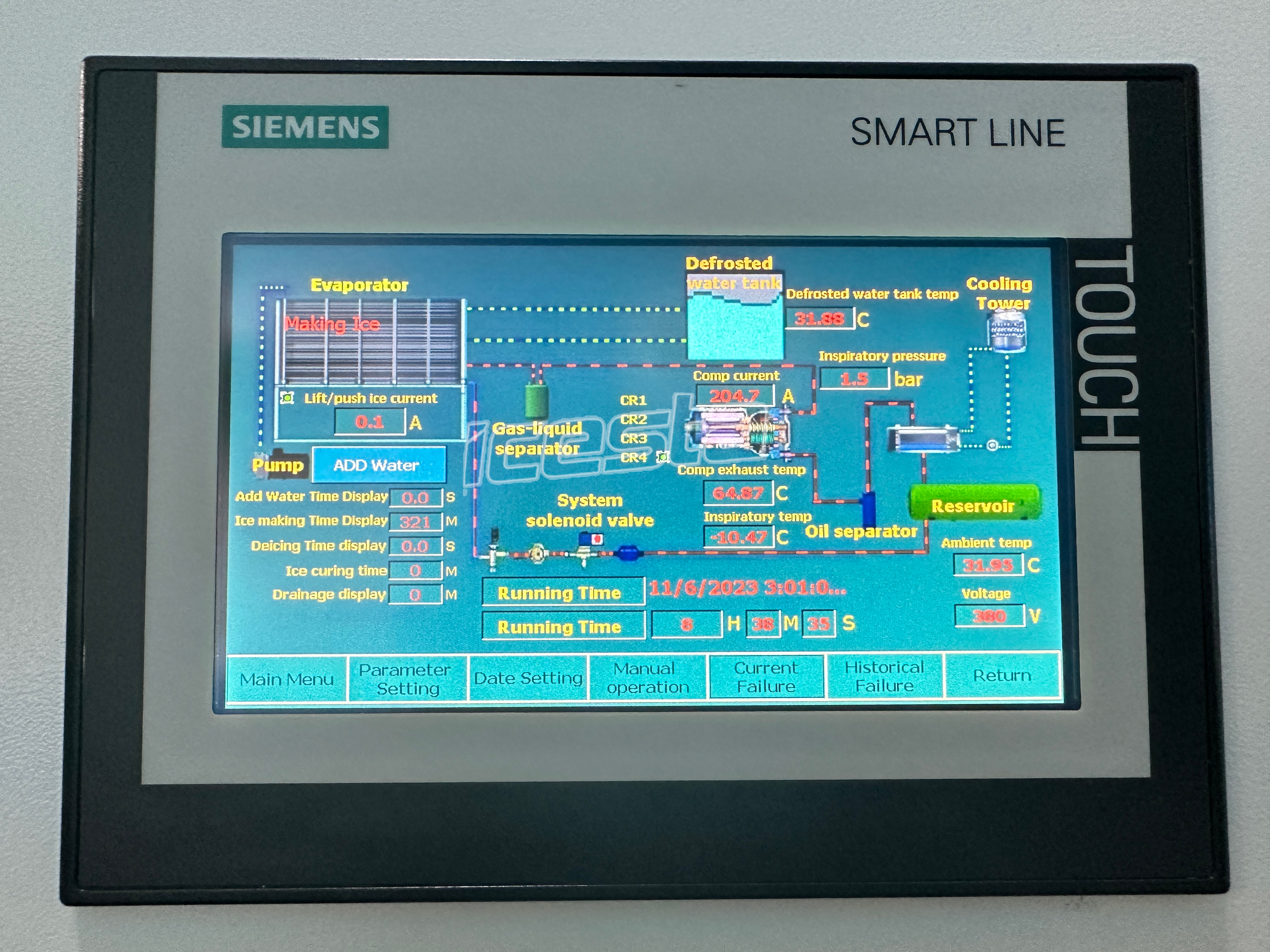

2) Intelligent Control System: Equipped with an advanced PLC automatic control system, automating the entire process from water injection, ice making, de-icing to ice storage. It is user-friendly and ensures stable operation.

3) Versatile Ice Output: Includes two fully stainless steel ice crushers to break large blocks into smaller pieces of various sizes, directly meeting the diverse ice needs of fishing boats, seafood markets, processing plants, etc.

4) Quality Assurance: The entire system underwent rigorous machinery testing and video outgoing-inspection before shipment, with warranty provided for core components, ensuring delivery quality.

* Project Outcome & Client Value

The completion and operation of this 120-ton ice plant have delivered immediate value to the Yemen Arab Investment Group and the Hodeidah region:

1) Stable Supply, Securing Industry: It has become a reliable giant "ice reservoir" for the locality, fundamentally changing the previous situation of unstable ice sources hindering fishery production and significantly reducing post-catch loss rates.

2) Improved Quality & Efficiency, Energy Saving: Automated production reduces labor dependence, and large-scale ice making lowers unit energy consumption. High-quality block ice extends the shelf life and transport radius of seafood.

3) Technology Enablement, Setting a Benchmark: The project demonstrates ICESTA's capability to deliver large, complex industrial projects in extreme climates. The high reliability of its equipment has earned high recognition from the client. This establishes a solid application benchmark for ICESTA in the Middle East and similar markets.

Related Products: