Icesta Slurry Ice Making System - 400 Tons/Day Capacity

Product advantages

The Icesta Slurry Ice Making System with a 400 tons/day capacity offers an efficient and reliable solution for producing high-quality slurry ice. This system is equipped with advanced technology that ensures fast and energy-efficient ice production, saving both time and resources. With its superior cooling performance and easy operation, the Icesta Slurry Ice Making System is the ideal choice for industries requiring large quantities of slurry ice for various applications.

Team strength

Our Icesta Slurry Ice Making System boasts a 400 tons/day capacity, ensuring efficient and reliable ice production for various industries. Behind this cutting-edge technology is a team of highly skilled engineers and technicians who work tirelessly to design and manufacture top-of-the-line ice making systems. With years of experience and industry expertise, our team is dedicated to delivering superior quality products and exceptional customer service. Trust in our team's strength to provide you with the perfect solution for all your ice production needs, allowing you to focus on growing your business with confidence.

Why choose us

In the world of industrial ice production, team strength is key to success. With the Icesta Slurry Ice Making System boasting a massive 400 tons/day capacity, a strong and skilled team is essential to ensuring smooth operation and maximum efficiency. Our team of experts is dedicated to providing top-notch service and support, from installation to maintenance and beyond. With years of experience and a deep understanding of the industry, our team is equipped to handle any challenge that comes our way. Trust in our team's strength to deliver exceptional results and keep your business running smoothly.

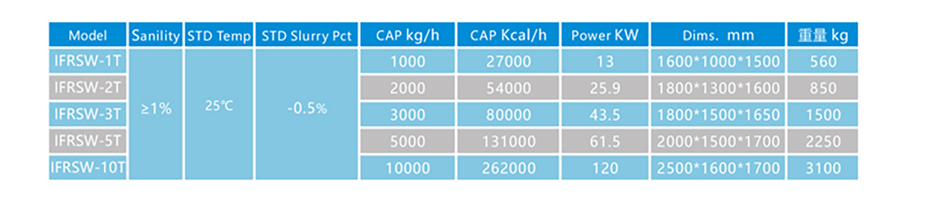

What is Seawater Slurry Ice

With wide experience in ice making equipment for more than one decade, ICESTA can design and fabricate different types of seawater & brine water slurry ice making equipment suitable for varied applications. Seawater ice crystals, when mixed with chilled seawater, turns to gel status, which is called liquid/slurry/fluid ice.

Advantages of Slurry Ice

1: Seawater Ice Slurry is a brand new type of ice which is different from traditional solid ice. It is a mixture of seawater tiny ice crystals and chilled seawater.

2: Fluidity of slurry ice allows pipe transportation; Liquid status and latent heat enable rapid chilling.

3: The products that are to be chilled can be fully immersed in slurry/liquid ice, which allows 100% contact and rapid chilling.

4: Slurry/liquid ice can be delivered to all desired ice use points via soft pipe & piping, which dramatically saves operational costs.

5: Larger contact area and quicker cooling shortens chilling time by 1/3.

Picture display

Technology, change the world, innovate, and subvert tradition.

We are committed to making people's production and life more convenient, efficient and beautiful

Saudi Arabia

400tons per day ice slurry system

Saudi Arabia

400tons per day ice slurry system

Saudi Arabia

ICESTA’s Slurry Ice Applications Compact

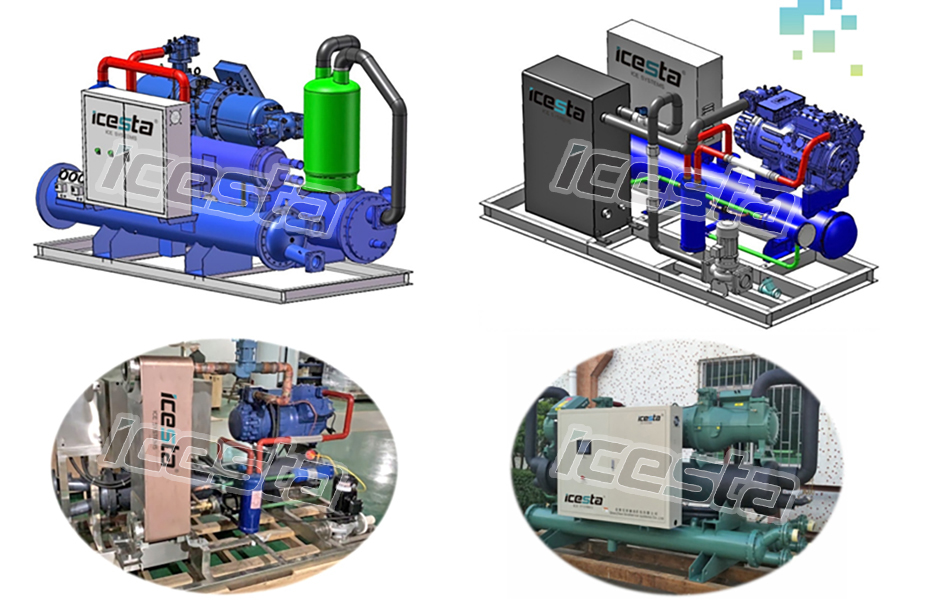

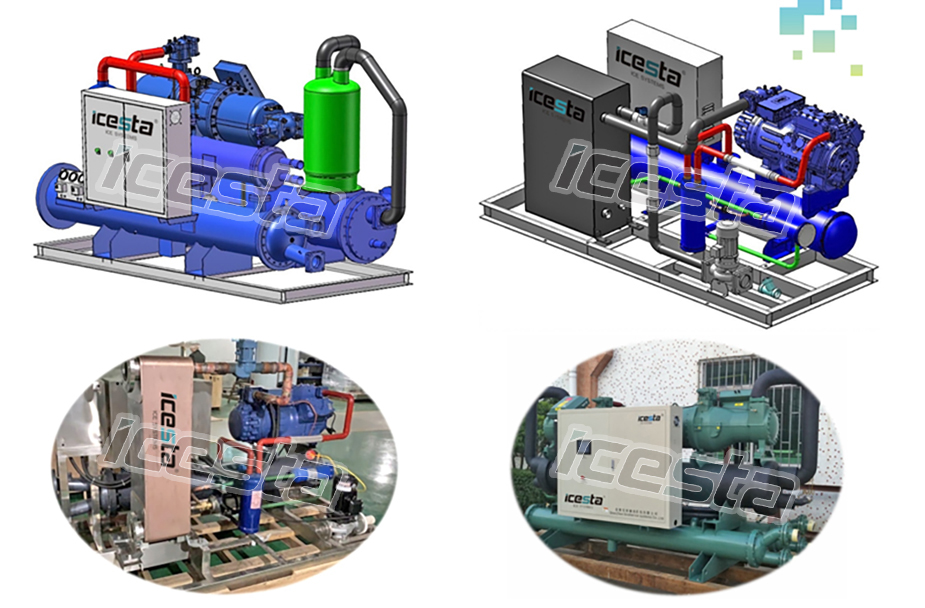

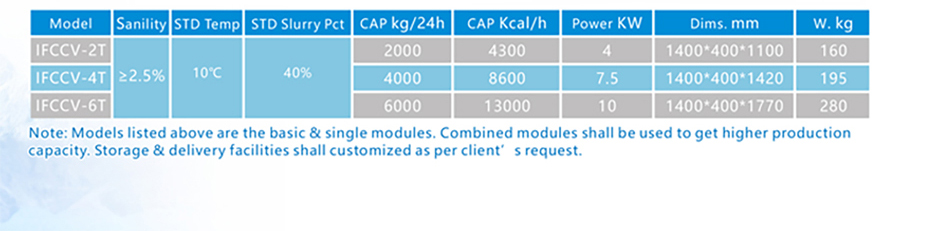

Slurry Ice Equipment

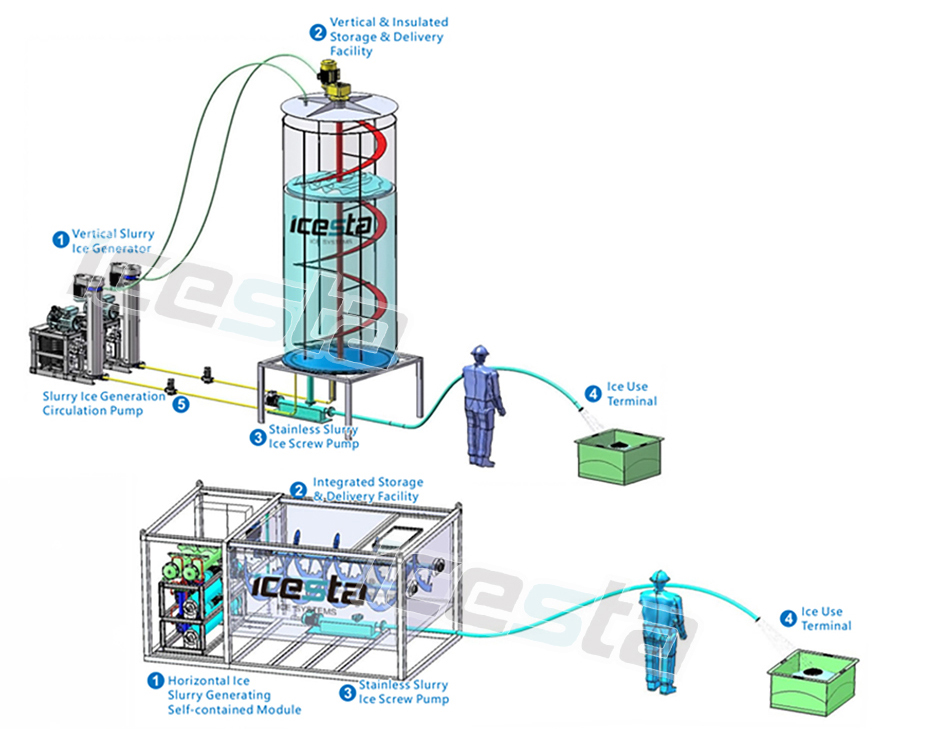

For seawater slurry ice applications of 40% concentration and required capacity lower than 15 tons, we are recommending scraping type ice generating system of single or combined modules.

For confined installation area, fishing vessels for example, we are using remote type, which separates condensing unit from ice making unit and storage and delivery facility. Flexible pipes are used to connect all the composing parts for easy maintenance. A remote start and stop button is installed at the delivery facility for automatic ice delivery.

Vertical slurry ice storage facility is available at clients’ request, which ranges from 1m³ to 30m³ (refer to page 10 for details). Slurry ice shall be transported via screw pump at ice concentration of 20% to 70%.

When the installation area is limited, an integrated module seawater slurry ice making & delivery system shall be recommended. It is easy of installation and mobilized. Storage facility for this system is recommended to reach a maximum capacity of 15 cubic meters. Stainless steel 316L or food-grade anti- corrosive plastic is used as the material when it is in contact with seawater to reach Hygiene standards.

Slurry ice generating system can have various environmentally friendly refrigerants R448A/R449A/R407F/R404A and R507.

You may contact us for for customized designs.

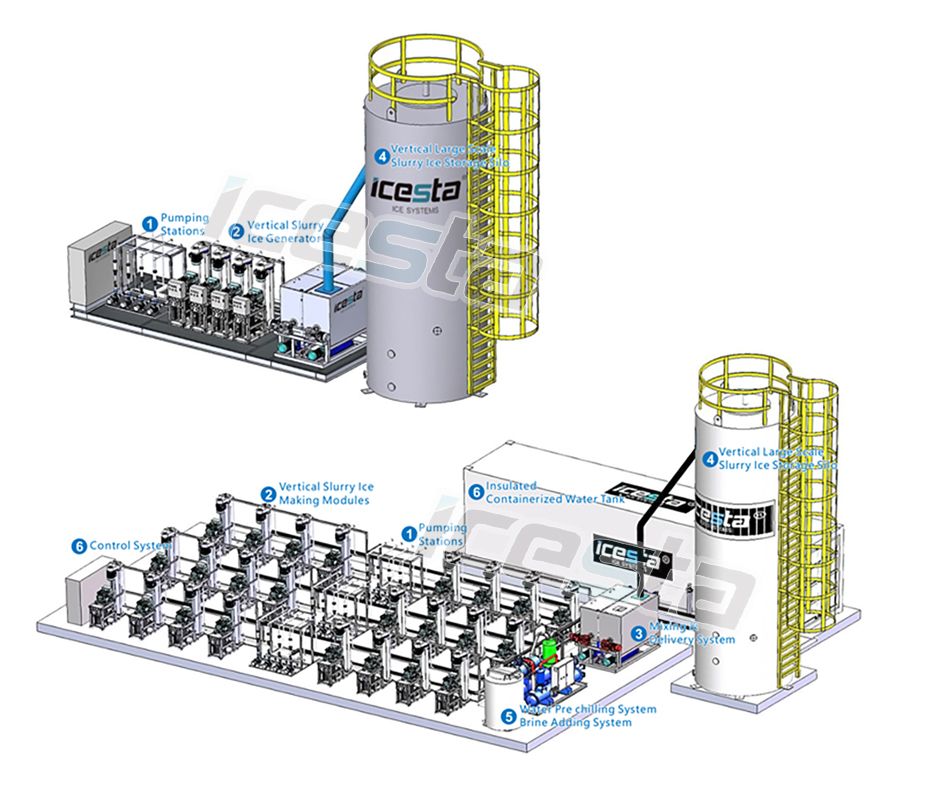

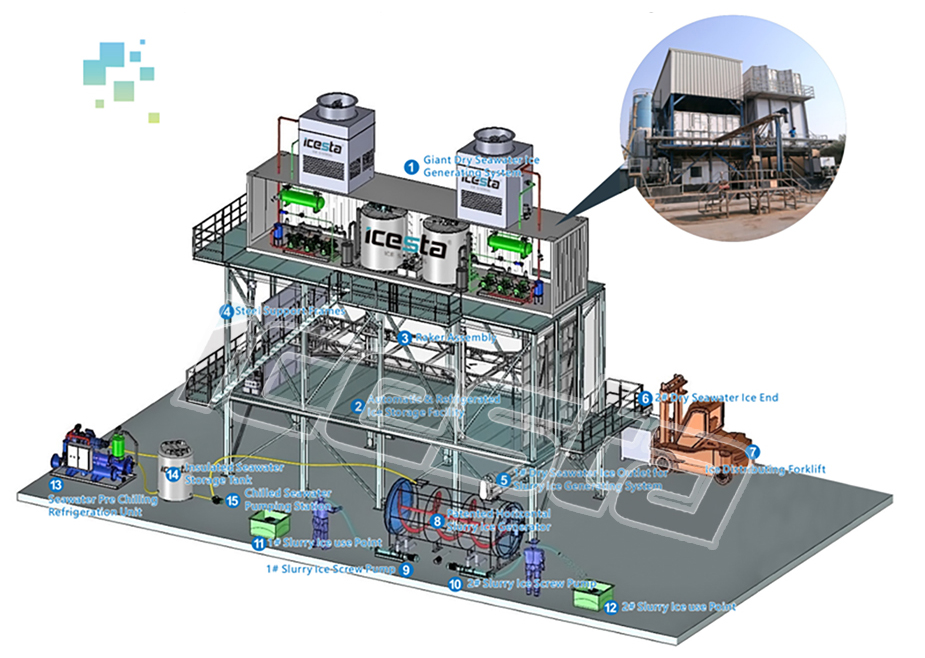

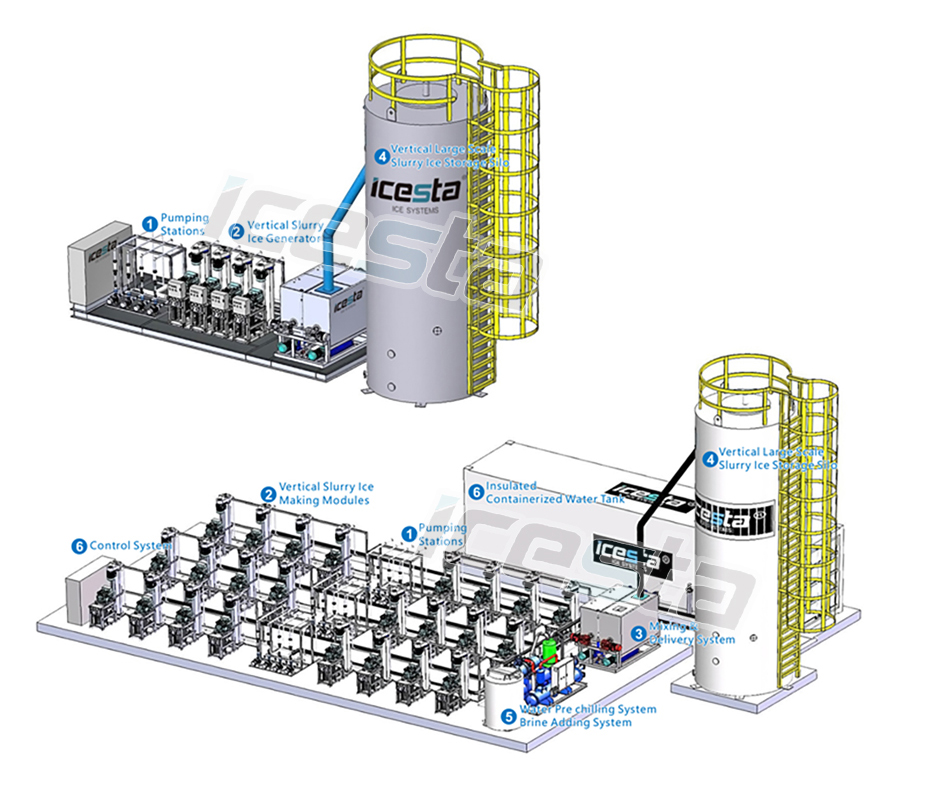

Modularized Large-Scale Slurry Ice Equipment

◪Modularized to realize Large scale slurry ice making system as per client’s request.

◪Each Single ice making unit is separate from and coordinate with each other to make ice slurry

◪Flexible configuration to increase and decrease production capacity.

◪A complete system is composed by pumping stations, ice making modules, storage facility, mixing & delivery system and control system.

◪Materials in contact with ice are stainless steel 316L or food-grade anti-corrosive plastic.

◪Seawater pre chilling system is suggested for large scale ice slurry making system to maximize energy- efficiency. Ice slurry system can be a customized and turnkey project.

◪A maximum daily production capacity of 1,000 metric tons of ice slurry can be reached with modularized design ice making system.

◪Contact our Sales team or agent for more details regarding customized design of modularized large scale ice systems.

◪Cost Effective Single Unit slurry ice making system which ranges from 2 mt to 30 mt per day.

◪Ice making unit is a semi-hermetic structure, which allows easy observation of ice making status and maintenance.

◪Ice Making units are in compliance with PED pressure vessel directives and highly reliable.

◪Generous Evaporation Area and Production Capacity.

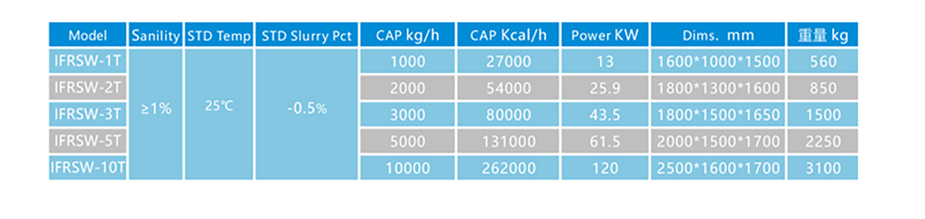

◪Applicable with virtually any seawater all over the world. Applicable Sanility: 1-3.5%.

◪Direct Ice slurry delivery or External Ice slurry mixing and delivery.

![Icesta Slurry Ice Making System - 400 Tons/Day Capacity 16]()

![Icesta Slurry Ice Making System - 400 Tons/Day Capacity 17]()

![Icesta Slurry Ice Making System - 400 Tons/Day Capacity 18]()

![Icesta Slurry Ice Making System - 400 Tons/Day Capacity 19]()

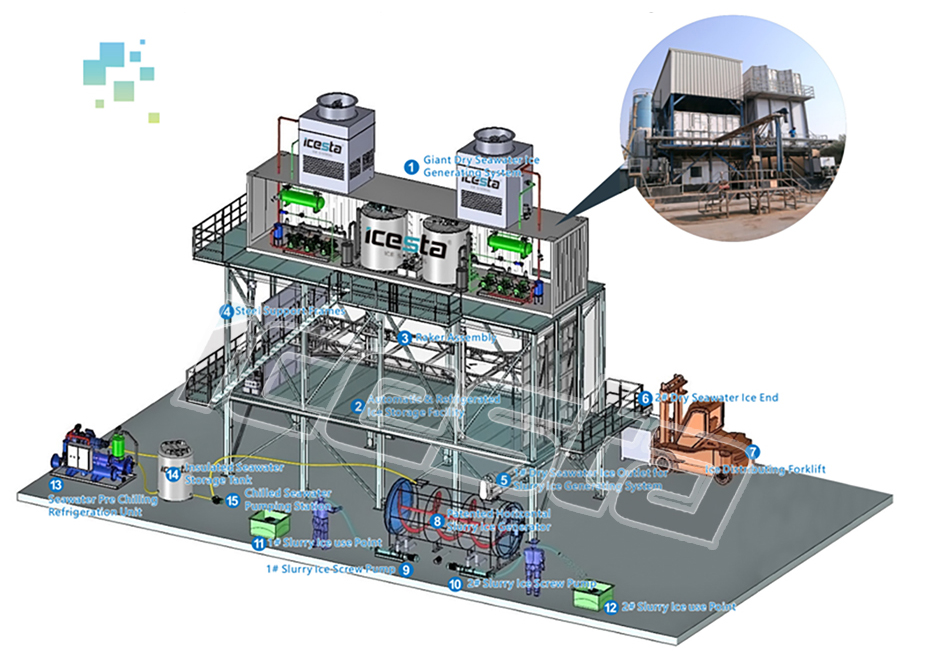

- Large Scale Dry Flake and Slurry Ice Making Equipment

◪1. In large scale aquacultural factories or ice distributing center, both dry and slurry ice shall be needed for purposes of best chilling effect and ice selling. ICESTA managed to design an integrated and patented ice making system which produces both slurry ice and dry seawater flake ice. They are now successfully operating in big aquacultural factories and ice distributing centers in Saudi Arabia and Maldives.

Soft seawater flake ice and chilled seawater, when mixed and agitated with our patented slurry

generating system, becomes slurry fluid ice suitable for fish preservation and transportation.

◪ Ice Making System shall make comparatively dry seawater flake ice and store in an automatic and refrigerated ice storage facility, where both discharge ends are open for slurry ice generation at one end, and dry seawater ice at the other. At the slurry ice generation end, dry seawater ice is discharged into our patented ice generating system and at the same time, chilled seawater is pumped in. When mixed properly, the mixture turns to gel status slurry ice. With the Screw pump located underneath, the slurry ice can be pumped to various desired ice use points.

◪ The Maximum slurry ice production can be 1,000 metric tons of ice concentration of 20% and 200 metric tons dry seawater ice alternatively. Please contact our sales team or agents for more details

![Icesta Slurry Ice Making System - 400 Tons/Day Capacity 20]()

![Icesta Slurry Ice Making System - 400 Tons/Day Capacity 21]()

![Icesta Slurry Ice Making System - 400 Tons/Day Capacity 22]()

![Icesta Slurry Ice Making System - 400 Tons/Day Capacity 23]()

![Icesta Slurry Ice Making System - 400 Tons/Day Capacity 24]()

FAQ

Advantages

About Brother Ice System

Four Major Brands

Quick Links

Contact Us

+86 755 2991 4211 - 803 (Tel.)

+86 755 29914210 (Fax)

+86 17665486066 (Cel)

Whatsapp: +86 17665486066

Wechat: +86 17665486066

EMAIL: laurene.luo@icesta.com

SKYPE: icesta-laurene