The main features of the spiral freezer are:

1. Space saving: The spiral design allows for vertical stacking during the freezing process, optimizing the footprint while handling large quantities of products.

2. Continuous operation: The product is fed into the conveyor belt, which spirals through the freezing chamber, allowing the food to flow continuously and thus improving processing efficiency.

3. Rapid freezing: Spiral freezers usually use quick freezing technology to quickly reduce food temperature, maintain texture, and minimize ice crystal formation.

4. Temperature control: They adopt precise temperature and airflow control design to ensure consistent freezing effect for all products.

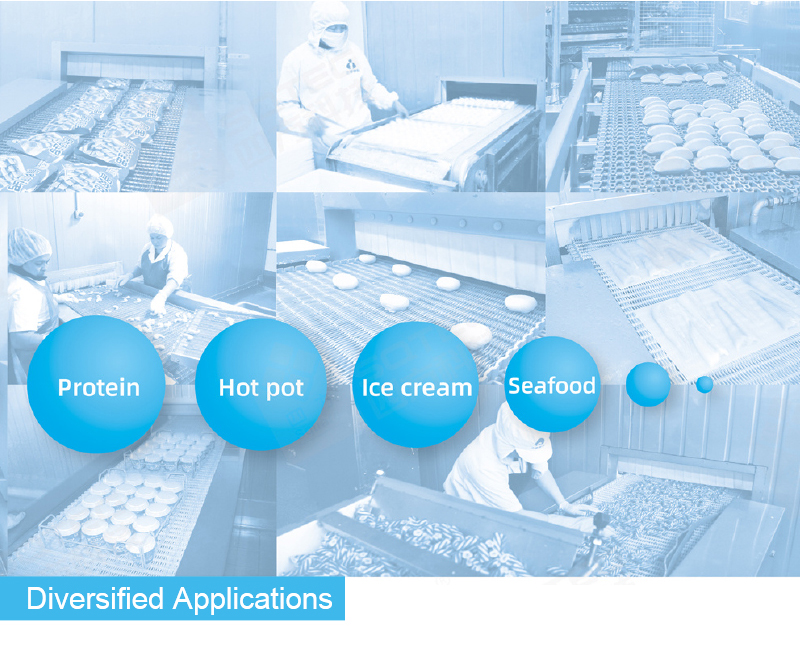

5. Multifunctionality: These quick freezing machines can process a variety of foods, including meat, seafood, baked goods, and ready to eat foods.

6. Efficient energy utilization: Advanced design features such as insulated walls and efficient airflow systems help reduce energy consumption.

The main features of the spiral freezer are:

1. Space saving: The spiral design allows for vertical stacking during the freezing process, optimizing the footprint while handling large quantities of products.

2. Continuous operation: The product is fed into the conveyor belt, which spirals through the freezing chamber, allowing the food to flow continuously and thus improving processing efficiency.

3. Rapid freezing: Spiral freezers usually use quick freezing technology to quickly reduce food temperature, maintain texture, and minimize ice crystal formation.

4. Temperature control: They adopt precise temperature and airflow control design to ensure consistent freezing effect for all products.

5. Multifunctionality: These quick freezing machines can process a variety of foods, including meat, seafood, baked goods, and ready to eat foods.

6. Efficient energy utilization: Advanced design features such as insulated walls and efficient airflow systems help reduce energy consumption.

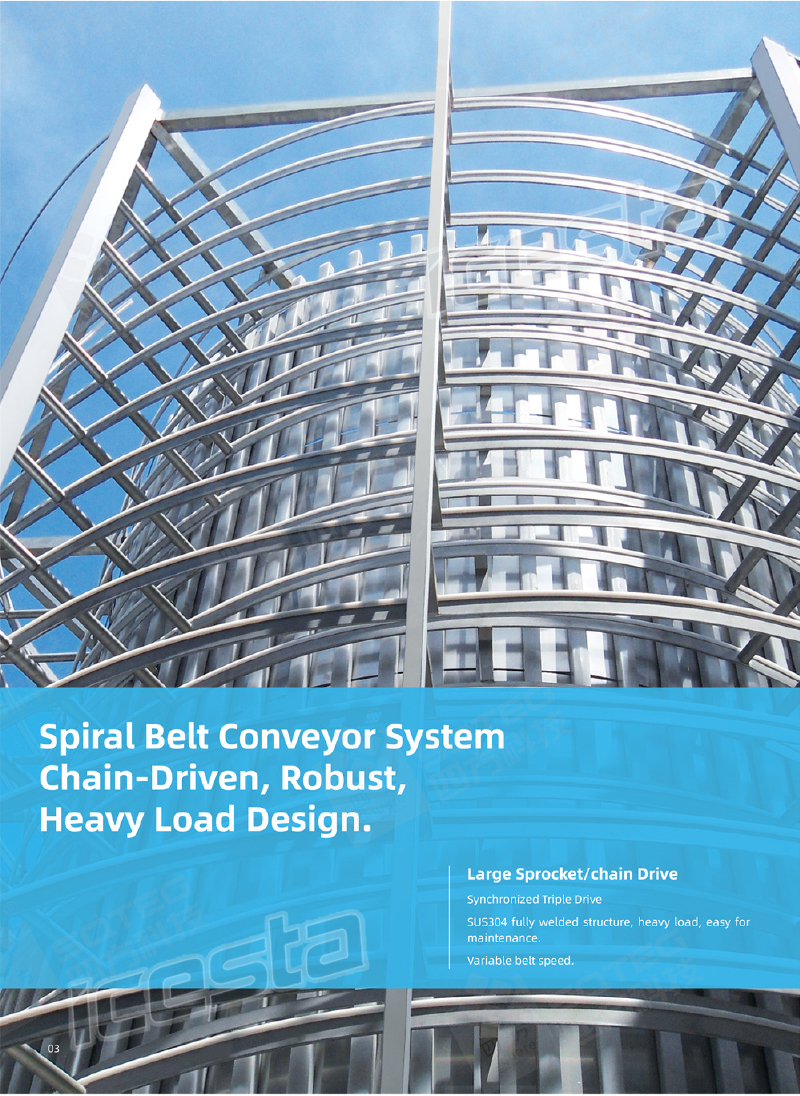

Technical Date

Structure | Double spiral freezer |

| Drum Diameter | 1620~5800mm |

| Layers | 6~40 |

| Insulated Enclosure | PIR/PU,SS skin at both sides |

| Mesh Belt Width | 520~1220mm |

| Infeed length | 500mm |

| Outfeed length | 500mm |

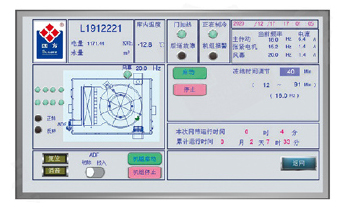

| Control panel | PLC touch screen, SS panel |

| Refrigerant | Freon, Ammonia, CO₂ |

| Evaporator | Al/SS tube, aluminum fin, variable fin pitch |

| Defrost | Water/hot gas/ADF optional |

| Freezing\cooling time | Stepless variable frequency adjustable |

| Cleaning | Manual\ Belt Washer\ ClP |

| Freezing capacity | 200 to 10000kg/h |

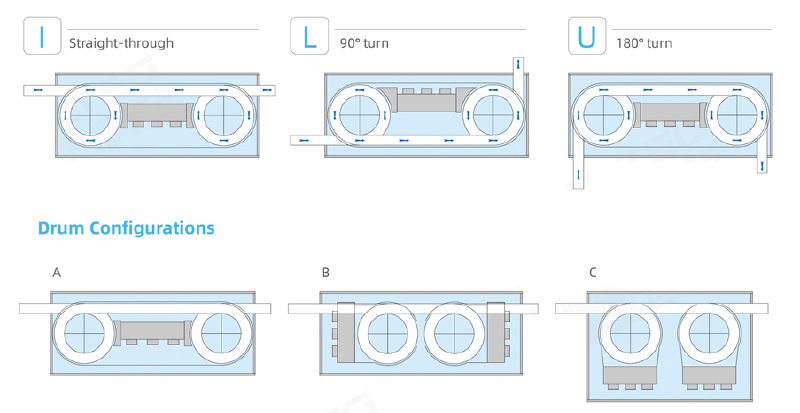

Infeed/ Outfeed Configurations

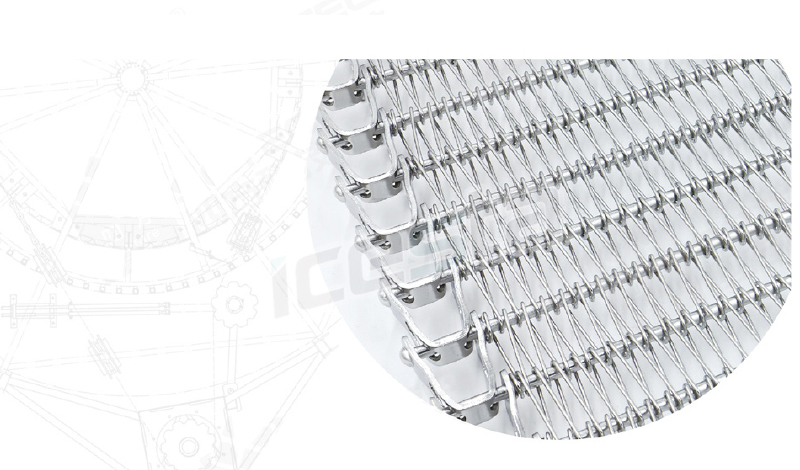

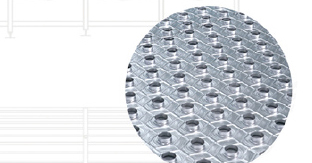

Stainless Steel Mesh Belt

SUS304 food-grade spring wire, high strength, 8–10 years of service life. Open structure, easy to clean, suitable width: 400–1372mm. Optional edge guard board to prevent products from dropping. High ventilation, high efficiency.

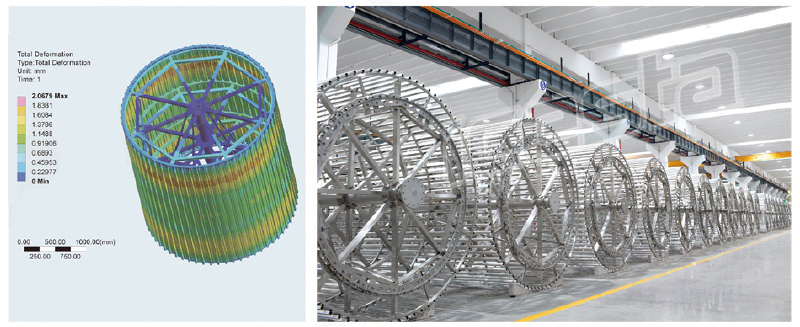

Finite Element Analysis

When Designing a spiral freezer, structural analysis is performed to ensure its structural integrity during operation

Tube material: Stainless steel, Aluminum Fin material: Aluminum

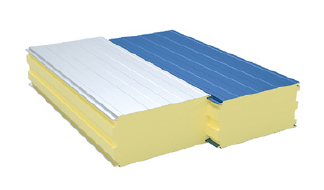

Insulated enclosure

Continuous PIR panel fabrication line from German Hennecke.

50mm to 250mm thick.

Limited combustibility.

Fully welded stainless steel enclosure available as option.

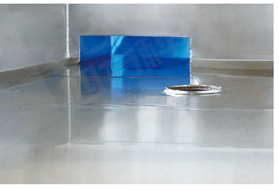

Fully welded floor

Modular stainless steel fully welded floor, leak proof.

Sloped floor, fast drainage through four drains at the corners. Easy Access.

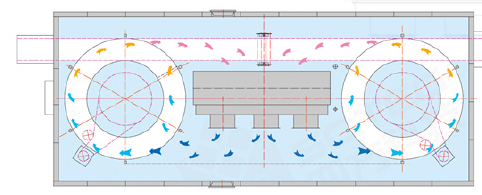

Air Flow Design

The cold and high velocity air flow is guided with the air baffles evenly through the product area. Minimum food dehydration, best heat transfer. Air shrouds provided to minimize cold loss at the opening of infeed and outfeed. Spacious access inside freezer for maintenance andcleaning personnel.

Intelligent, User-Friendly, Network

The ADF blows pulses of pressurized air of high velocity repeatedly over the evaporator fins while the products continue to run in the freezer. The freezer inside temperature is more stable because of less frost on the fin. Thanks to longer runtime, the production output isincreased.

Optional configuration

Product Hot Sale

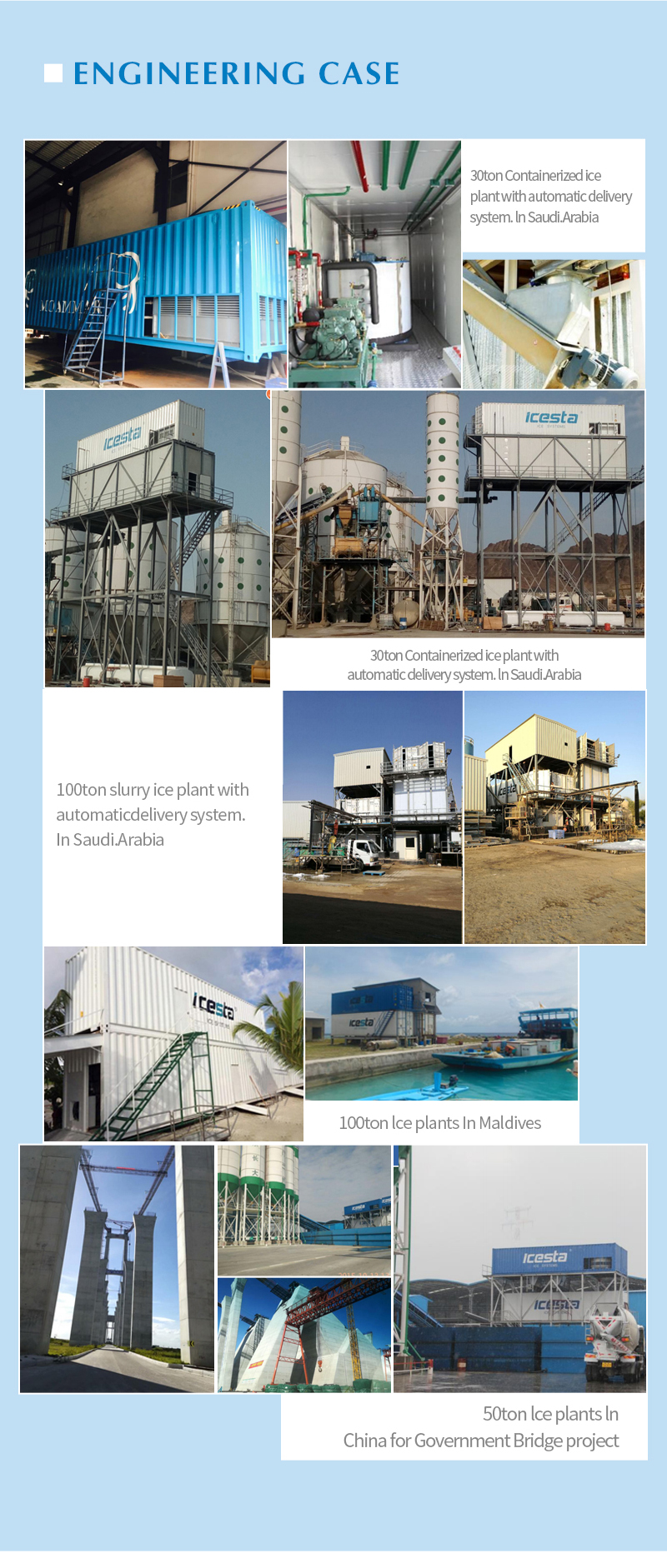

20 years focus on innovative solution in ice making and cooling technology

Shenzhen Brother Ice System Co., Ltd. ( ICESTA Brand), a well-known ice machine manufacturer and industry leader and pioneer in China.The product covers flake ice /Block ice machine, Tube ice /slurry ice/plate ice/cube ice machines, water chillers,Plate/spiral/blast freezers, Automatic ice storing & delivery system with integrated container ice system,artificial snow making machine.etc

* Experiences & History:

Dscades of Team focus on innovative solution in lce & Cooling technology.

Decadal Professional Manufacturer, Supplier of Excellent Tumkey ice & cooling projeds.

* Indlustry status& Reputation

Top lce Machine Brand in China.

20000 ㎡ Factory

ISO 9001 ,CE, PED,ASME (U.S ) Certifcates etc

* Technology& Management capability:

80+ patents

High Technology enterprise Certifcate

* Services & Global Net

Export to 80+ countries

Local service in 50+ countres with networks all over the world

1-2 years waranty covers each component.

Feel free to contact us

ICESTA has always adhered to the philosophy of “UNITED, PRECISION, INTERNATIONALIZED & OUTSTANDING”, from professional refrigeration team, strict quality system, efficient management mode, global development strategy, and customer-oriented. The business purpose of all is combined with this inner concept, thus laying a solid foundation for the realization of broad corporate goals.