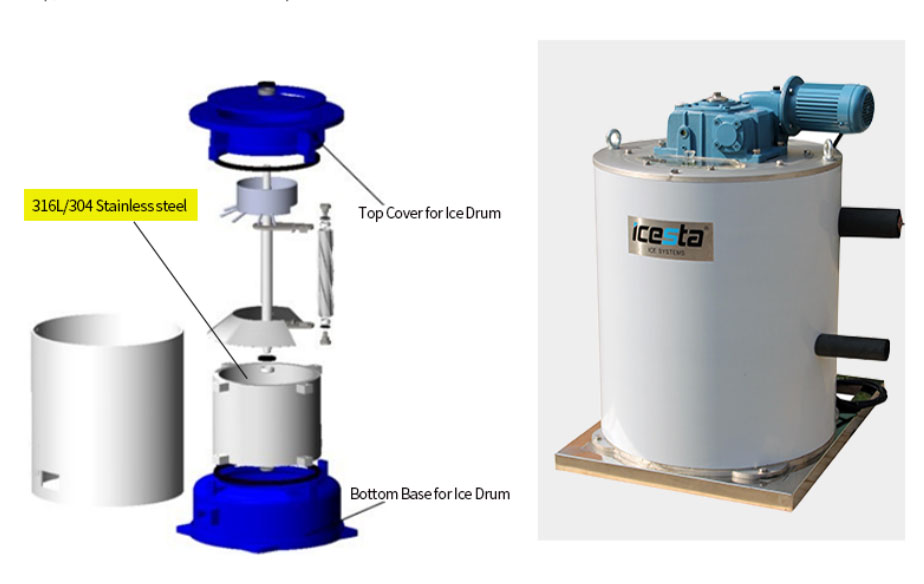

316L /304 Stainless steel ice flaker Drum(evaporator),High Anti-corrosive Standard.

Application:

Edible stainless steel flake ice machine 3-10t compared with similar products on the market, it has incomparable outstanding advantages in terms of performance, quality, appearance, etc., and enjoys a good reputation in the market.Brother Ice System summarizes the defects of past products, and continuously improves them. The specifications of Edible stainless steel flake ice machine 3-10t can be customized according to your needs.

In the deep processing of meat or other foods, the food is processed in the processing equipment chopper or dough mixer. The equipment generates a lot of heat during the high-speed chopping or mixing process, which results in the inaccurate control of the microbes of the food, which leads to the processing. The color of the food is dim and the taste is not good. At this time, it is necessary to add flake ice to control the temperature in the processing process to ensure that the processed food can not only ensure the taste and quality, but also improve the yield rate;

Application industry

More and more Coling or temp.Re duction industry used the ice machines to meet their higher technic request due to their deeper knowledge about this equpment.

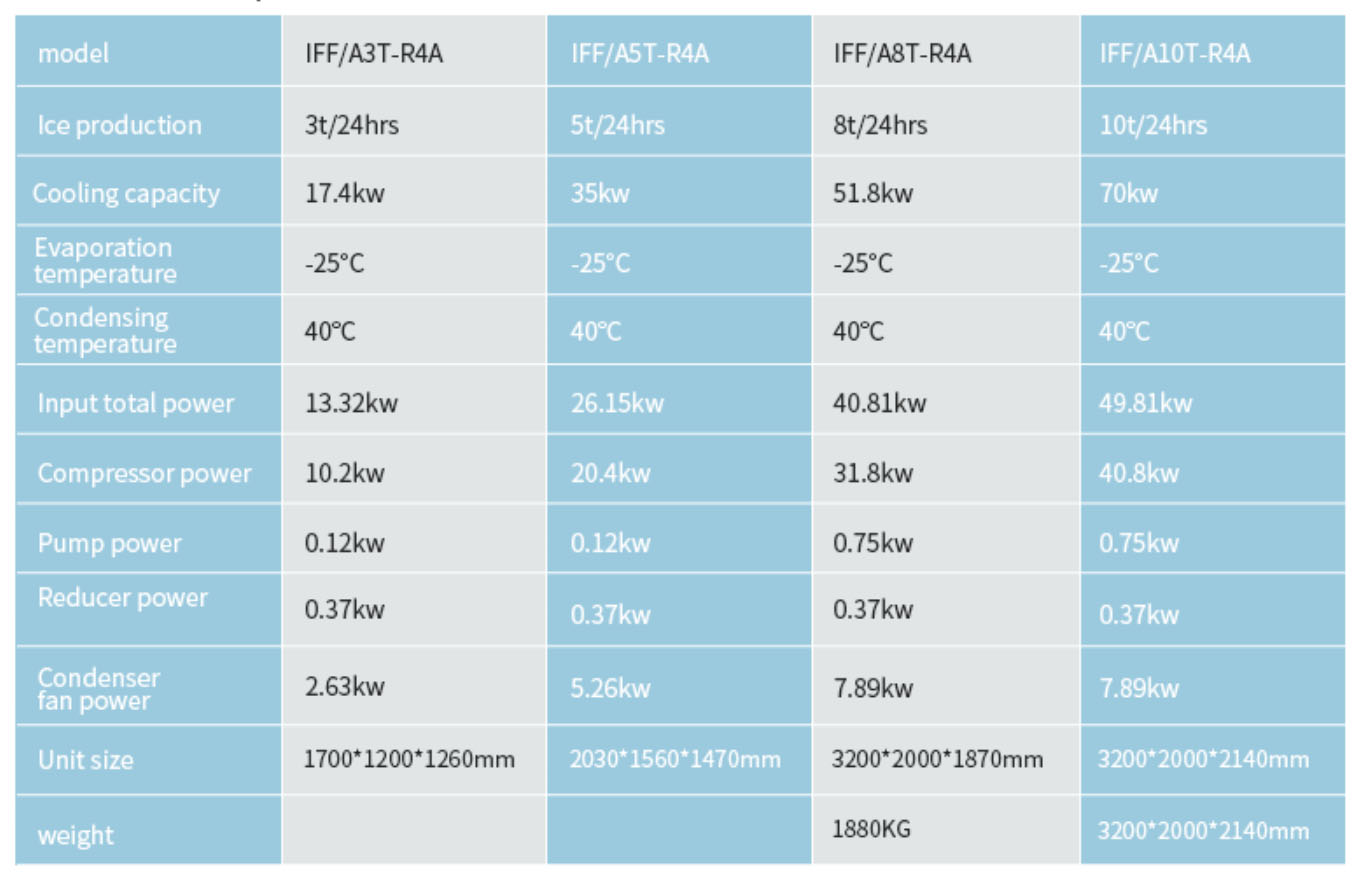

Technical Parameters

* The technical data based on 25°C ambient temp.20°C water inlet temp

* Power supply:3P/380V/50HZ,3P/220V/60HZ,3P/380V/60HZ,3P/460V/60HZ Optional

* The ice thickness:1.6-2.3mm.

* Refrigerant: R404A(R22 R17 R507 is optional)

3t,5t,8t,10t/24h

Show Details

ADVANTAGES / SPECIAL DESIGN FOR ice flaker on board use

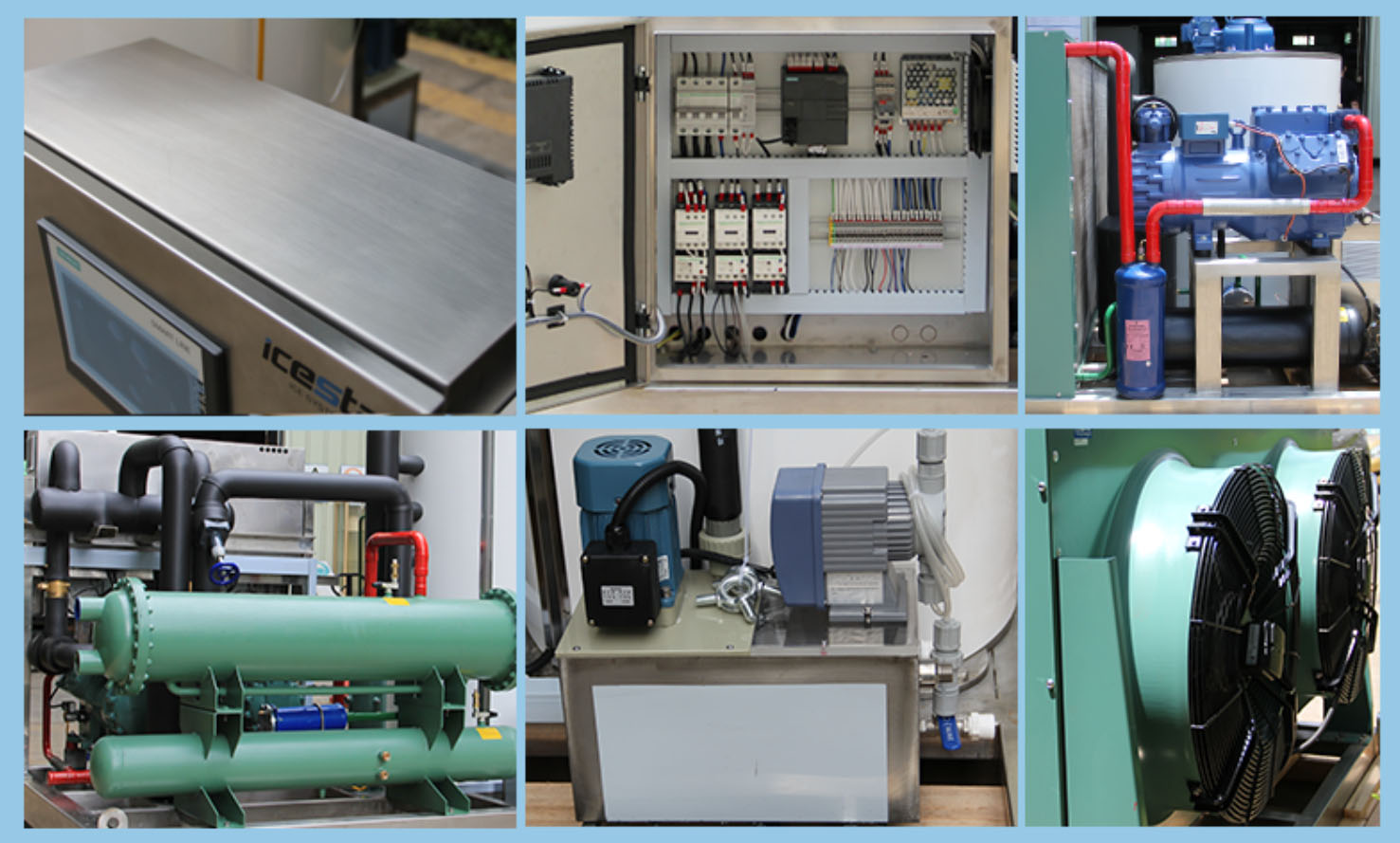

Material of evaporator:

External surface: Glass fiber steel (never getting rust)

Inner surface : 316L Stainless steel

(High reliability for anti-corrosion even feeding seawater for ice making)

Supporting base: 304 Stainless steel

Top/bottom cover of ice flake evaporator : 304 Stainless steel

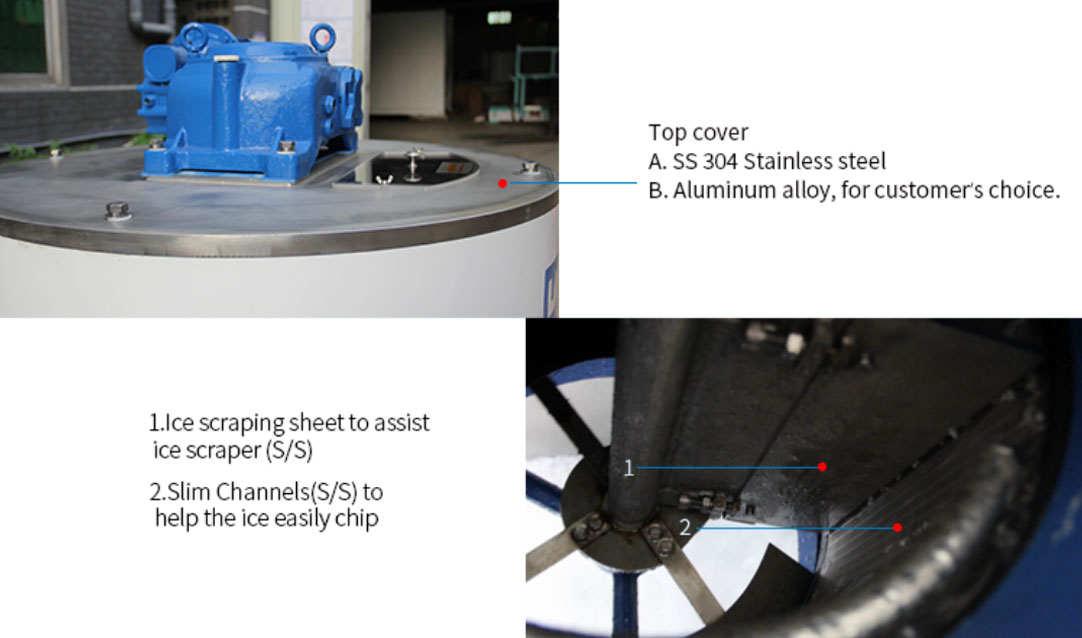

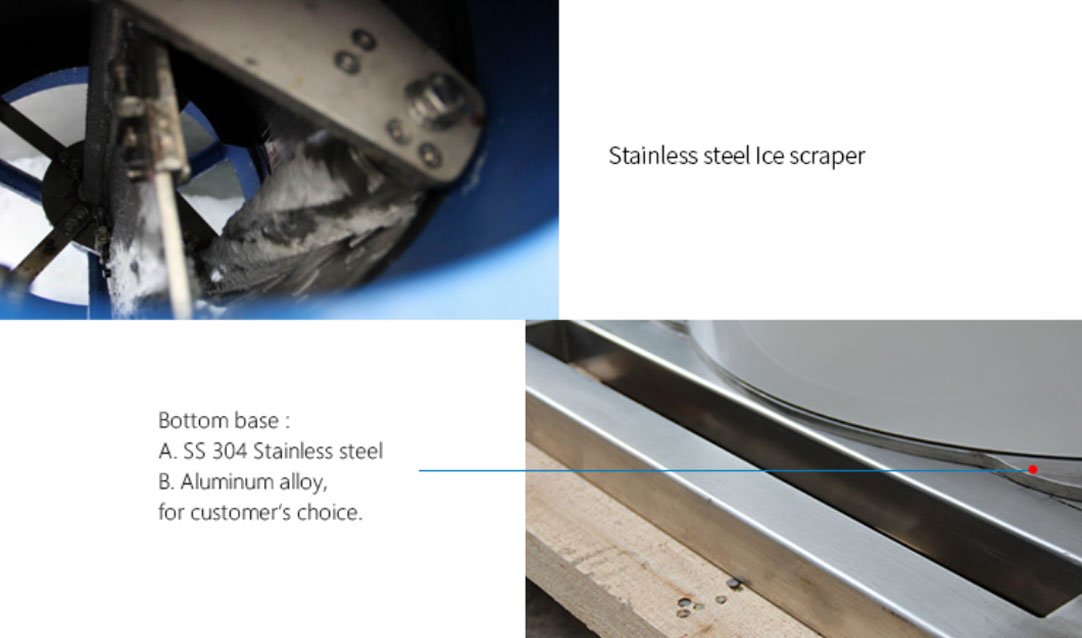

Material of Stainless Steel ice flake machine

All great works are moving in countless details, and every high-quality ice machine is precisely carved out of the details.

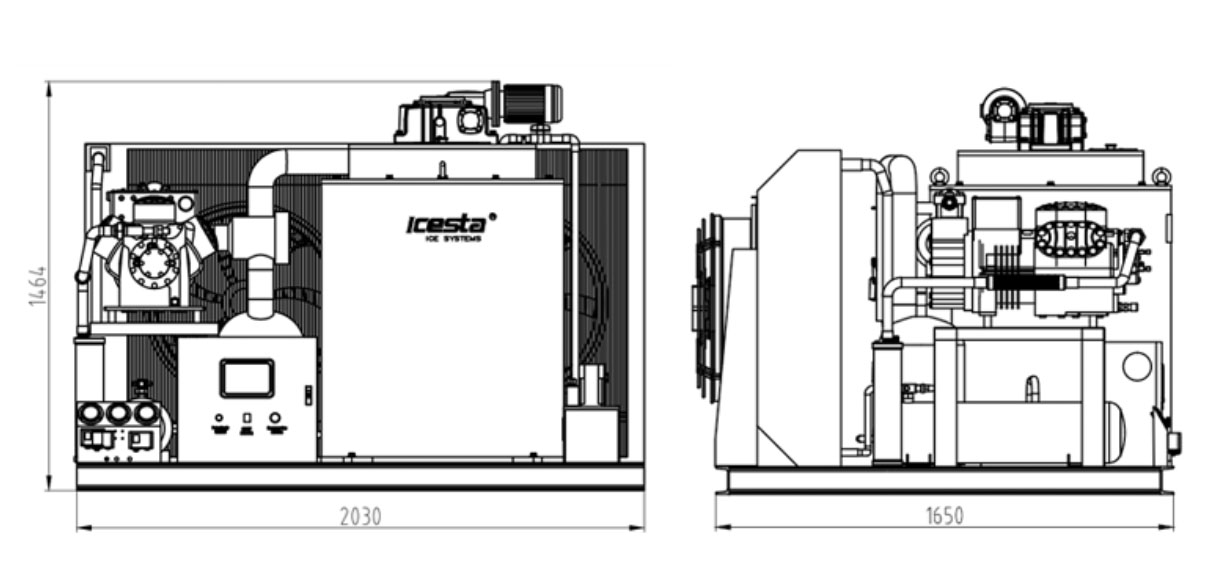

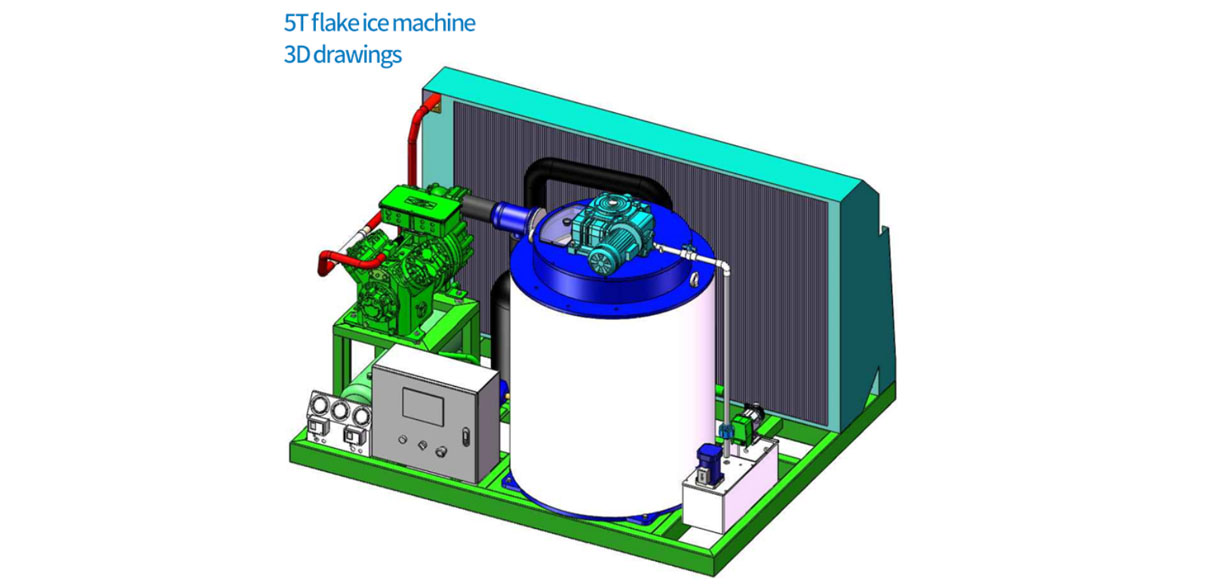

Drawing Display

The ICESTA team has used more than 20 years of experience in refrigeration and ice making to continuously innovate products to achieve higher efficiency, more stable operation, smoother ice removal and ice production.

Advantage

Advantages of ICESTA flake ice machine

1.Rigorous pick-up of raw material. Not every kind of Stainless Steel is the same in terms quality on the market. When we choose stainless steel, we use the material of high quality with Qualified Material Certificate only.

2.Compared to Carbon Steel, stainless steel evaporator and top/bottom covers requires a high criterion in the processes of welding, machining and Annealing. Coarse machining may make the machine prone to deformation and short life time. ICESTA fine and meticulous craftsmanship and innovative design makes our stainless steel evaporator endure.

3.Diversified choice. ICESTA provides customer oriented designs in accordance with machining artwork, working conditions and water quality, in an attempt to offer performance stability and ice use satisfaction as well as cost effectiveness.

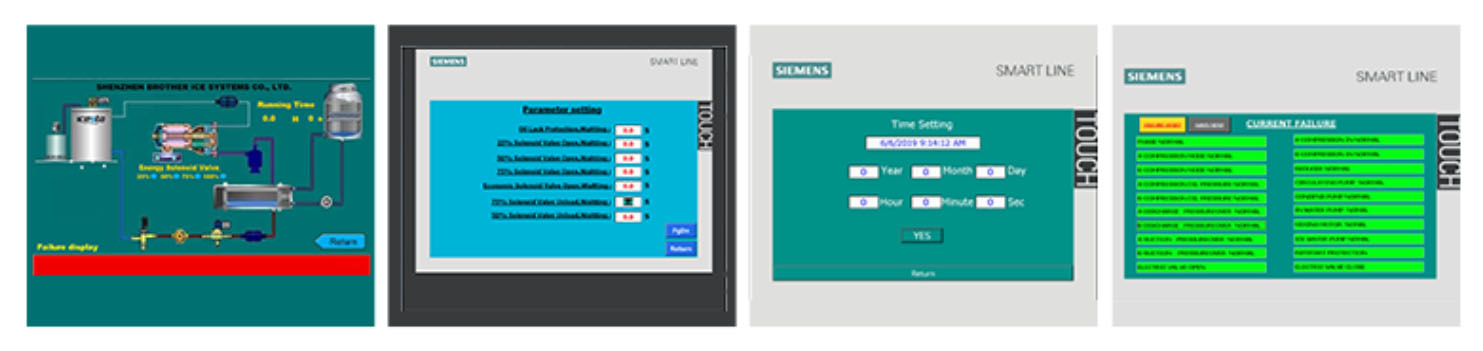

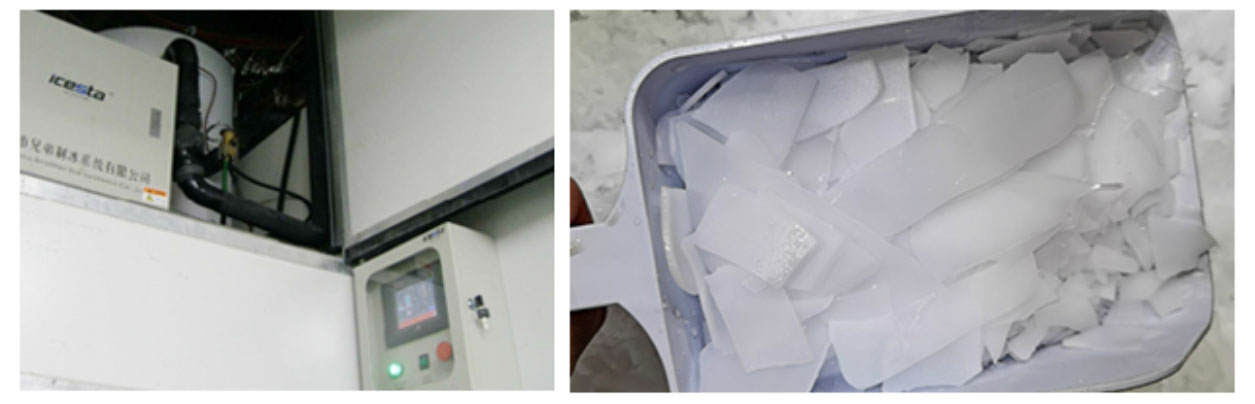

Intellectualized PLC controller with touch-screen

All failure record & instant solution available

Stop-time setting at will.

Different languages version

Elaborate details design gives all-sided convenience

Prominent Heat treatment to avoid any SRINKAGE

TOP welding testing technics with X-RAY——Never leak

Sufficient ice output

Picture Display

Technology, change the world, innovate, and subvert tradition. We are committed to making people's production and life more convenient, efficient and beautiful

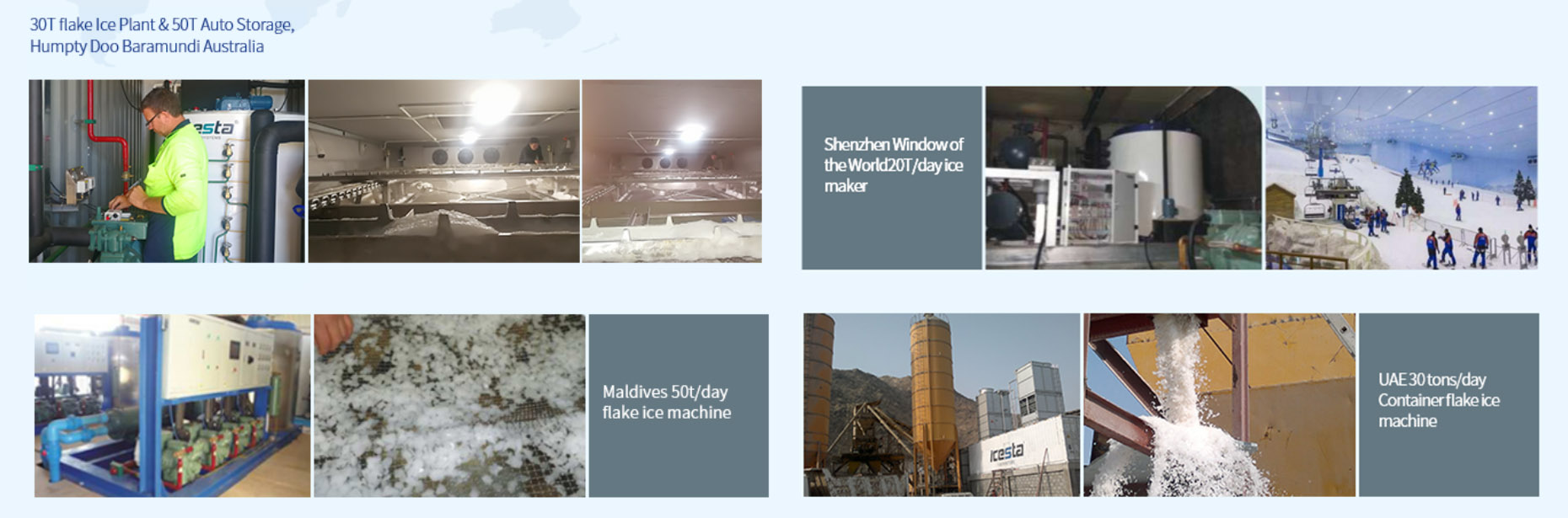

Engineering Case

Since 2007, ICESTA products have been sold to more than 80 countries around the world, and provide distributor services in many regions.

Product Hot Sale

Sea water flake ice machine

All-in-one Automatic (Containerized) ice making & Storage& Delivery system

ICESTA

20 years dedication in ice making technology to create excellence.

Shenzhen Brother Ice Maker System Co., Ltd. (hereinafter referred to as ICESTA), as a well-known ice-making equipment manufacturer and industry pioneer, since its establishment in 2007, it is committed to providing excellent "Made in China". Technological innovation and forge ahead, continuous expansion of product lines, continuous upgrades of products, and annual expansion of the factory.

There are more than 150 people in Shenzhen and Dongguan R&D, manufacturing, and sales bases, as well as production, management, and domestic and overseas technical teams. The annual output value is up to More than 120 million yuan; two branch companies were established: Shenzhen Brother Cold Chain Technology Co., Ltd., Liaoning Sports Sports Technology Co., Ltd.; three major brands: including ICESTA series of flake ice machines, block ice machines, tube ice machines, and ice slurry Machines, ice pellet machines, integrated ice storage and delivery container ice making systems, consumer and commercial ice machines, Brother series snow blowers, snow machines, Snowtek series block ice machine chillers, etc., have covered all mainstream ice in the world today It also expands to the field of cold chain equipment, such as chillers, freezers, cold storage equipment, etc., and at the same time provides various medium and low temperature refrigeration units for global industrial and commercial refrigeration equipment and engineering companies, so as to provide users with the most convenient and comprehensive use Ice and refrigeration solutions.

ICESTA's branded ice making equipment, with daily output ranging from 25Kg to 100 tons, is widely used in supermarkets, catering hotels, aquatic products and meat processing, poultry slaughter, leather manufacturing, chemical dyes, concrete construction, ocean fishing, artificial ski resorts, etc. industry. So far, ICESTA has obtained more than 40 national new patents, and has passed the European Union CE safety standards and PED pressure vessel certification, American AMSE certification, ISO9001 quality management system certification, national high-tech enterprise certification, etc., serving more than 80 customers worldwide Countries and regions.

ICESTA Customers & Certificate

Packages & Service

Packages & Service

FAQ

1.Failure Claim procedures

a. Detailed written failure description is required by fax or by mail, indicating the relevant equipment information and detailed description of failure.b. Relevant pictures are required for failure confirmation.c. ICESTA engineering and after-sales service team will check and form a diagnosis report.d. Further trouble-shooting solutions will be offered to customers within 24 hours after receiving the written description and pictures

2.Installation & commissioning

A. Installed by customers according to the manuals, online instructions and live video conference of ICESTA.B. Installed by ICESTA engineers.a. ICESTA would arrange 1~3 engineers based on the projects to the installation sites for the final supervision of all installations and commissioning.b. Customers need to provide local accommodation and round-trip ticket for our engineers and pay for the commissions. US Dollars 100 per engineer per day.c. Power, water, installation tools and spare parts need to be ready before ICESTA engineers arrive.

3.Questions before quotation

A. Would you make ice from seawater, saltwater or freshwater?B. Where and when would the machine be installed roughly?The ambient temperature and water inlet temperature?C. What’s the power supply?D. What is the application of the flake ice produced?E. Which cooling mode would you prefer to? Water or air ,Evaporative cooling?

Advantages

1.Any failure occurred within the period due to our responsibility, ICESTA will supply the spare parts for free.

2.Over 25 engineers for instant after-sale services and more than 15 are available for serving overseas.365 days X 7 X 24 hours phone / EMAIL assistance

3.Permanent technical support & consultation all life long for the machines.

4.ICESTA provide full technical support and training courses after equipment installation and commissioning.

About Brother Ice System

Shenzhen Brother Ice Systems Co., Ltd. is (ICESTA for short) located in Shenzhen of China. Our company is a professional manufacturer and exporter specializing in designing and supplying innovative ice solutions worldwide with our own ICESTA ice machines.With a senior professional refrigerating team, modern operating conception, ordered efficient management model, and global strategy, ICESTA has founded a substantial base to tend towards the global market, then play an important role in the fresh keeping and cooling in the field of aquatic food & meat processing, ocean-going fishing, fowl slaughtering, concrete construction project, large supermarket and chain stores, dye chemical industry, mining and medical facilities.In line with our customer-oriented philosophy, ICESTA management is actively aligning the business structure to well meet customers' needs with a wide range of products, excellent quality as well as credible service. As a professional exporter, ICESTA will strive to create maximum value for our esteemed clients.

Product introduction

Stainless Steel Flake ice machine, whose freezing surface (in contact with water) of ice making evaporator is made of Stainless Steel Material (SS316L or SS304), is characteristic of high anti-corrosion and anti-rust performance. This feature makes ICESTA ice plant a superb companion for food processing industry which requires high level of hygiene and deep-sea fishing boat etc where only seawater is available for ice making.

Feel free to contact us

ICESTA has always adhered to the philosophy of “UNITED, PRECISION, INTERNATIONALIZED & OUTSTANDING”, from professional refrigeration team, strict quality system, efficient management mode, global development strategy, and customer-oriented. The business purpose of all is combined with this inner concept, thus laying a solid foundation for the realization of broad corporate goals.