Stainless Steel Flake ice machine, whose freezing surface (in contact with water) of ice making evaporator is made of Stainless Steel Material (SS316L or SS304), is characteristic of high anti-corrosion and anti-rust performance. This feature makes ICESTA ice plant a superb companion for food processing industry which requires high level of hygiene and deep-sea fishing boat etc where only seawater is available for ice making.

CATEGORY:Flake Ice Making System

Product Description

STAINLESS STEEL FLAKE ICE MACHINE(Food Grade)

316L /304 Stainless steel ice flaker Drum(evaporator),High Anti-corrosive Standard.

· PRODUCT INTRODUCTION

Stainless Steel Flake ice machine, whose freezing surface (in contact with water) of ice making evaporator is made of Stainless Steel Material (SS316L or SS304), is characteristic of high anti-corrosion and anti-rust performance. This feature makes ICESTA ice plant a superb companion for food processing industry which requires high level of hygiene and deep-sea fishing boat etc where only seawater is available for ice making.

· APPLICATION INDUSTRY

More and more Coling or temp.Re duction industry used the ice machines to meet their higher technic request due to their deeper knowledge about this equpment.

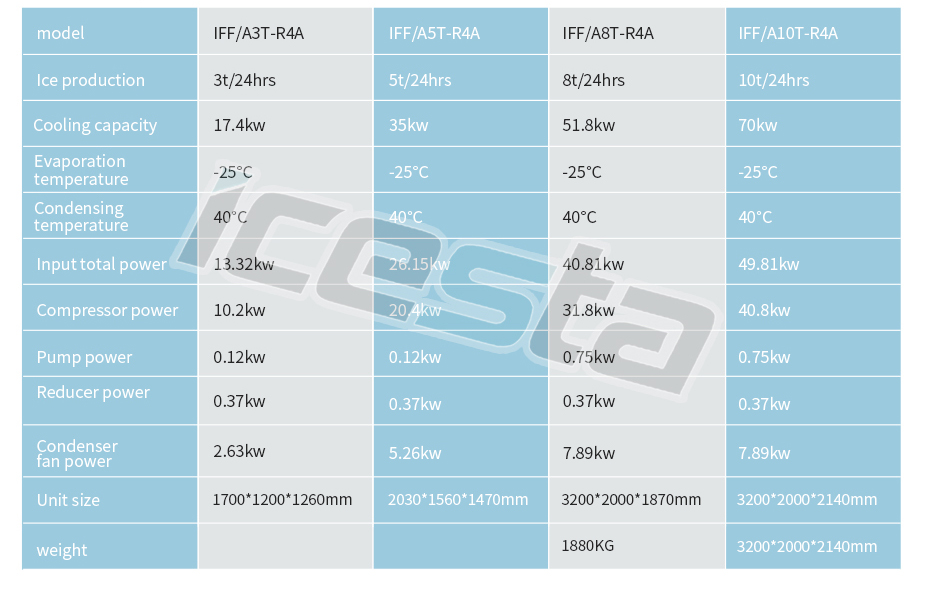

· TECHNICAL PARAMETERS

*The technical data based on 25°C ambient temp.20°C water inlet temp

* Power supply:3P/380V/50HZ,3P/220V/60HZ,3P/380V/60HZ,3P/460V/60HZ Optional

* The ice thickness:1.6-2.3mm

* Refrigerant: R404A(R22 R17 R507 is optional)

3t,5t,8t,10t/24h

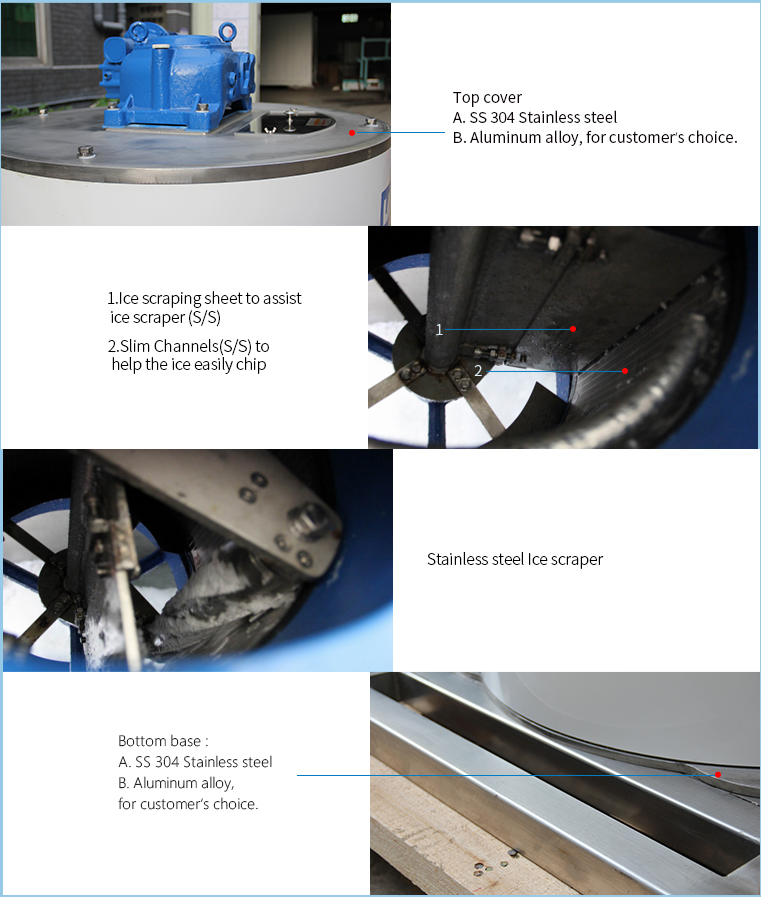

· SHOW DETAILS

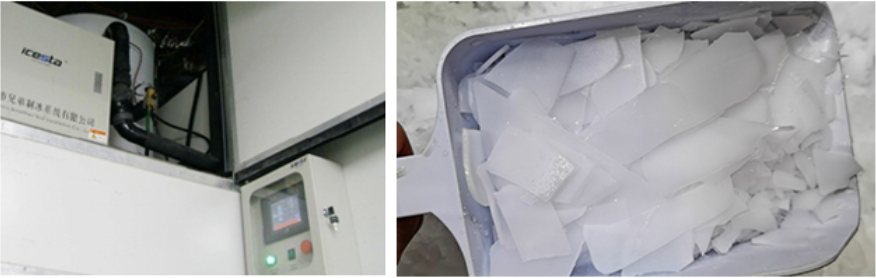

ADVANTAGES / SPECIAL DESIGN FOR ice flaker on board use

Material of evaporator:

External surface: Glass fiber steel (never getting rust)

Inner surface : 316L Stainless steel

(High reliability for anti-corrosion even feeding seawater for ice making)

Supporting base: 304 Stainless steel

Top/bottom cover of ice flake evaporator : 304 Stainless steel

· Material of Stainless Steel ice flake machine

All great works are moving in countless details, and every high-quality ice machine is precisely carved out of the details.

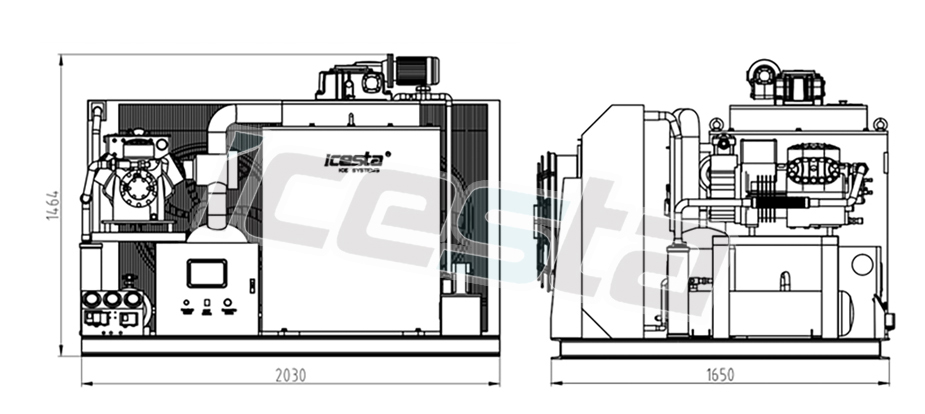

· DRAWING DISPLAY

The ICESTA team has used more than 20 years of experience in refrigeration and ice making to continuously innovate products to achieve higher efficiency, more stable operation, smoother ice removal and ice production.

5T flake ice machine

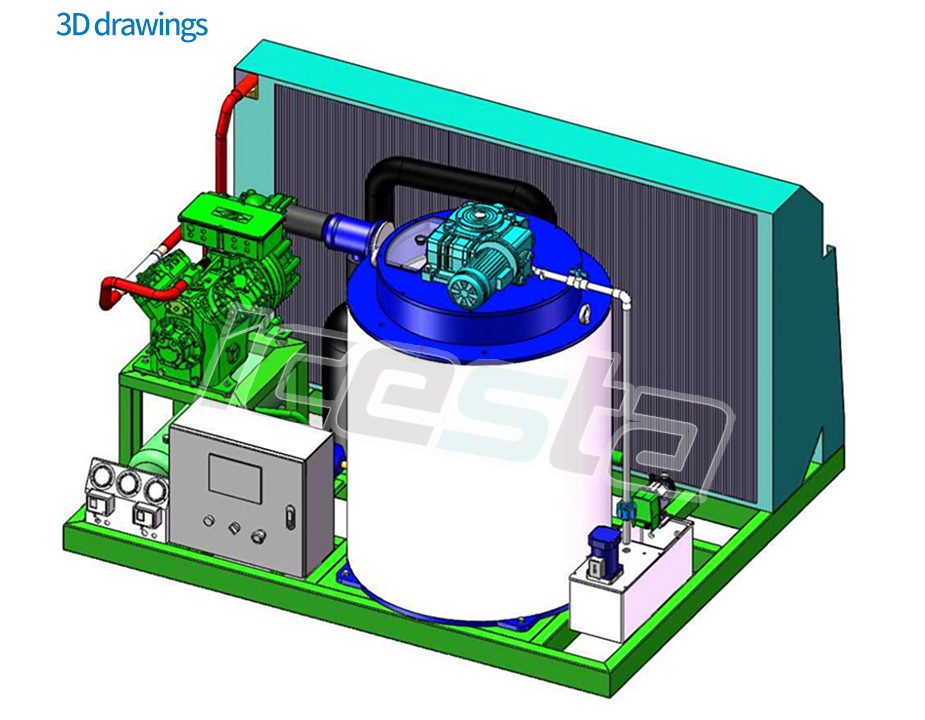

3D drawings

· ADVANTAGE

Advantages of ICESTA flake ice machine

1.Rigorous pick-up of raw material. Not every kind of Stainless Steel is the same in terms quality on the market. When we choose stainless steel, we use the material of high quality with Qualified Material Certificate only.

2.Compared to Carbon Steel, stainless steel evaporator and top/bottom covers requires a high criterion in the processes of welding, machining and Annealing. Coarse machining may make the machine prone to deformation and short life time. ICESTA fine and meticulous craftsmanship and innovative design makes our stainless steel evaporator endure.

3.Diversified choice. ICESTA provides customer oriented designs in accordance with machining artwork, working conditions and water quality, in an attempt to offer performance stability and ice use satisfaction as well as cost effectiveness.

Intellectualized PLC controller with touch-screen

· All failure record & instant solution available

· Stop-time setting at will.

· different languages version

Elaborate details design gives all-sided convenience

· Prominent Heat treatment to avoid any SRINKAG

· TOP welding testing technics with X-RAY——Never leak

· Sufficient ice output

PICTURE DISPLAY

Technology, change the world, innovate, and subvert tradition. We are committed to making people's production and life more convenient, efficient and beautiful

Engineering case

30T flake Ice Plant & 50T Auto Storage,

Humpty Doo Baramundi Australia

Since 2007, ICESTA products have been sold to more than 80 countries around the world, and provide distributor services in many regions

Feel free to contact us

ICESTA has always adhered to the philosophy of “UNITED, PRECISION, INTERNATIONALIZED & OUTSTANDING”, from professional refrigeration team, strict quality system, efficient management mode, global development strategy, and customer-oriented. The business purpose of all is combined with this inner concept, thus laying a solid foundation for the realization of broad corporate goals.