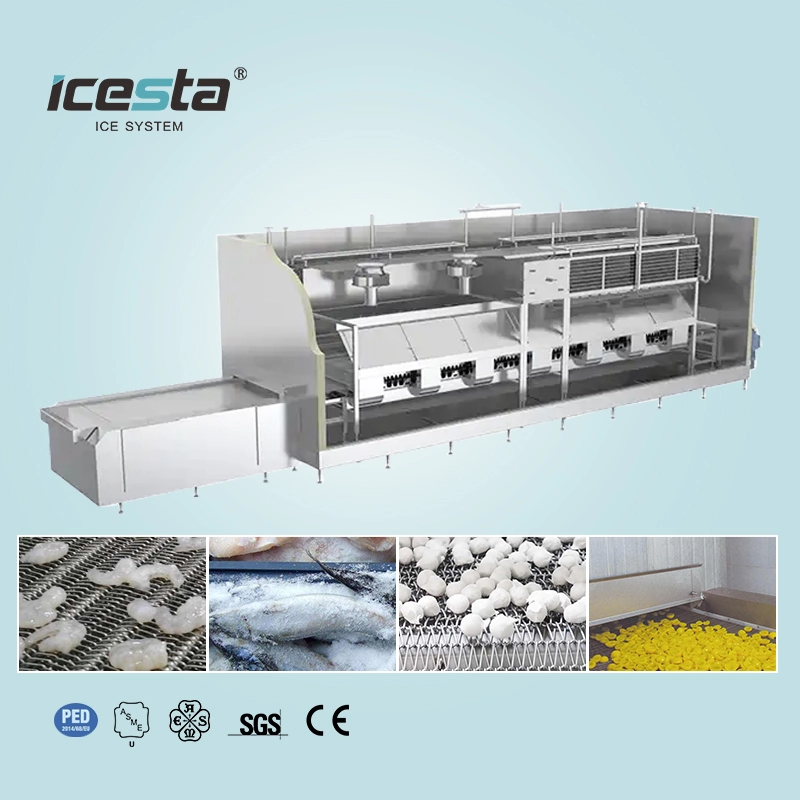

Tunnel Freezer with Iqf Processing Line Automic Cryogenic Durian Quick Freeze For Food Processing Industry

A Tunnel Freezer is an industrial equipment that achieves continuous freezing through a tunnel-shaped chamber structure, mainly used for batch low-temperature processing in food, pharmaceutical, and other industries. By conveying materials via a conveyor belt and combining with low-temperature circulating air, it realizes uniform freezing of materials during transportation. It features high efficiency, stability, and high automation, suitable for large-scale assembly line production.

Product Introduction

A Tunnel Freezer is an industrial equipment that achieves continuous freezing through a tunnel-shaped chamber structure, mainly used for batch low-temperature processing in food, pharmaceutical, and other industries. By conveying materials via a conveyor belt and combining with low-temperature circulating air, it realizes uniform freezing of materials during transportation. It features high efficiency, stability, and high automation, suitable for large-scale assembly line production.

Product Parameter

| Product Name | Tunnel Freezer |

| Insulated Enclosure | PIR/PU, double sides stainless steel panel |

| Control Panel | PLC touch screen, SS panel |

| Refrigerant | Freon, Ammonia, CO₂ |

| Evaporator | Al/SS tube, aluminum fin, variable fin pitch |

| Defrost | Water/hot /ADF optional |

| Freezing/Cooling Time | Stepless variable frequency adjustable |

| Freeze Time | 4-40mins |

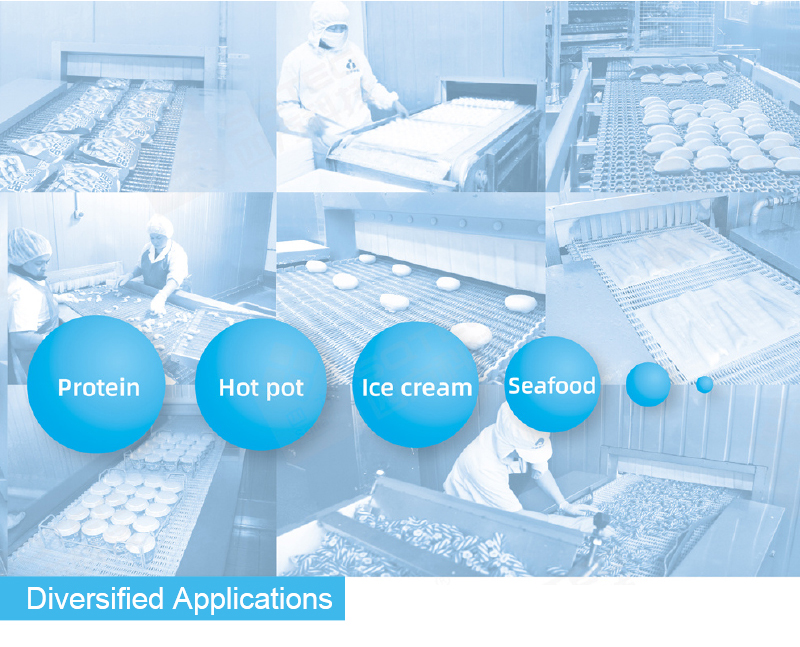

Application

• Food Processing: Meat cuts (pork, beef, mutton), aquatic products (shrimp/fish/shellfish), frozen convenience foods (dumplings/baozi), ice cream/ice pops, baking ingredients (dough/cream).

• Cold Chain Logistics: Central kitchen pre-made food freezing, e-commerce fresh food storage pretreatment, large cold storage pre-cooling.

• Pharmaceuticals and Chemicals: Low-temperature storage of biological preparations, freezing and solidification of chemical raw materials (explosion-proof configuration available for customization).

Product Advantages

1.High-Efficiency Continuous Production:

24-hour uninterrupted operation, matched with assembly line production, can significantly improve refrigeration efficiency and reduce labor costs.

2.Uniform Freezing Quality:

The stable temperature field inside the tunnel and the high consistency of material freezing can avoid cell damage and preserve the taste and nutrition of food, suitable for standardized quality control.

3.Energy Optimization:

Centralized refrigeration coupled with variable frequency drive (VFD) technology achieves 15-20% energy savings compared to conventional systems.

4.Flexible Customization:

The conveyor belt type, tunnel width, and airflow direction (up and down/left and right convection) can be customized according to the material size (such as block, particle, packaging), and the freezing time, temperature, and airflow distribution can also be adjusted according to product characteristics.

5.Easy Maintenance and Cleaning:

Modular structural design allows detachable evaporator cleaning, complying with HACCP food safety standards.

Detailed display

Leading Designer, Manufacturer, Supplier of Excellent Turkey lce & Cooling Solution since 2007..

1. Structural Design:

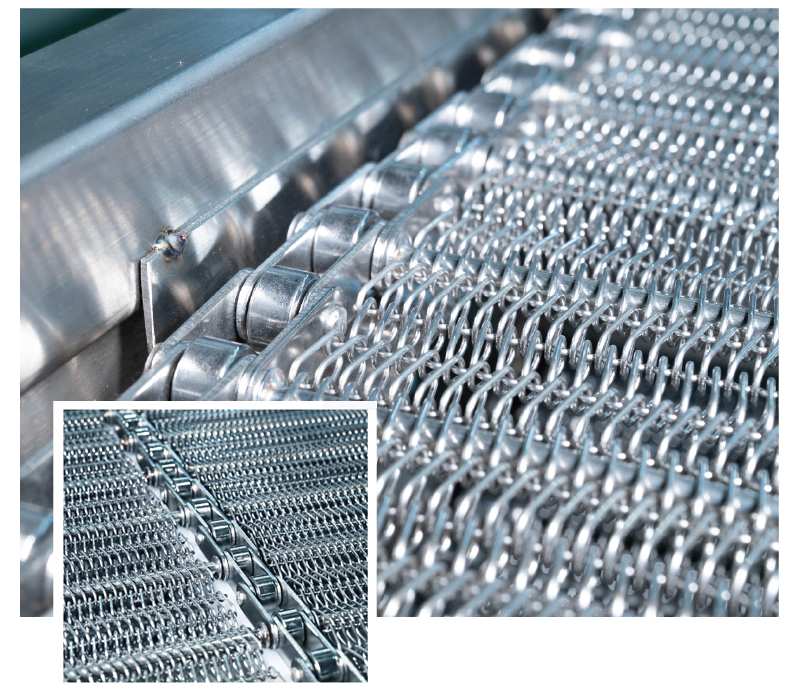

The main body is a long stainless steel tunnel chamber with a food-grade conveyor belt (mesh belt/chain plate/spiral belt) inside, supporting continuous material transportation.

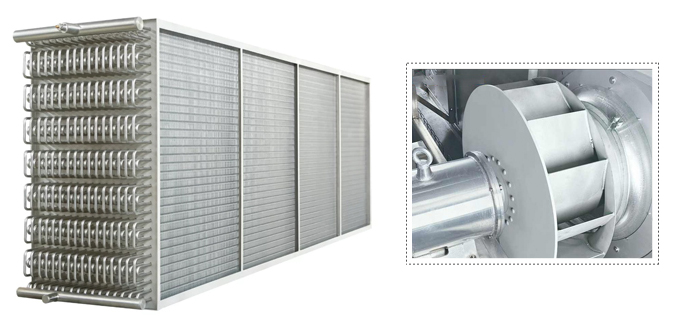

An efficient centrifugal fan is engineered to meet the demands for large air volume and high air velocity. The fan's structure is designed for effortless cleaning and maintenance. The fully-sealed motor ensures smooth operation and a prolonged service life.

The Air Defrosting System promptly clears frost from the evaporator fin surfaces during freezer operation, sustaining prolonged uninterrupted freezer performance, decreasing evaporator frost accumulation, and enhancing productivity.

The evaporator's design is modeled using professional European heat exchanger software. All tubes are hydraulically expanded rather than mechanically expanded, boostinfin surface, extending the frosting cycle while enabling easy access and cleanig heat exchange performance through more uniform expansion and a tighter tube-fin seal. Variable fin pitch is implemented to retard frost accumulation on the ng.

2:H-M Interactive Intelligent Control System

H-M Interactive Intelligent Control System with PLC Touch-Screen, friendly interface, easy operation, supporting real-time monitoring of operational parameters and pre-set freezing programs.Real-time display of equipment running status, the temperature of each area, and fault alarm. Preset freezing programs tailored for different products. Optional remote troubleshooting module

• Working Principle:

Materials are conveyed through the tunnel at a constant speed by the conveyor belt. Low-temperature air (-30°C to -40°C), driven by fans, fully contacts the material surface, achieving gradual freezing through heat conduction and convection. The freezing process can operate continuously for 24 hours without manual intervention

3.Materials and Safety:

The outer shell is made of 304 stainless steel, with a smooth inner wall for easy cleaning, complying with food-grade hygiene standards.

* Equipped with overload protection, leakage protection, and temperature anomaly alarms.

* Stainless Steel Conveyor Belt: Constructed with SUS304 food-grade spring steel wire mesh, this high-strength belt offers an 8-10 year service life. Its open-structured design (400-1372mm width range) ensures easy cleaning and excellent ventilation. An optional edge guard prevents product spillage while maintaining high operational efficiency.

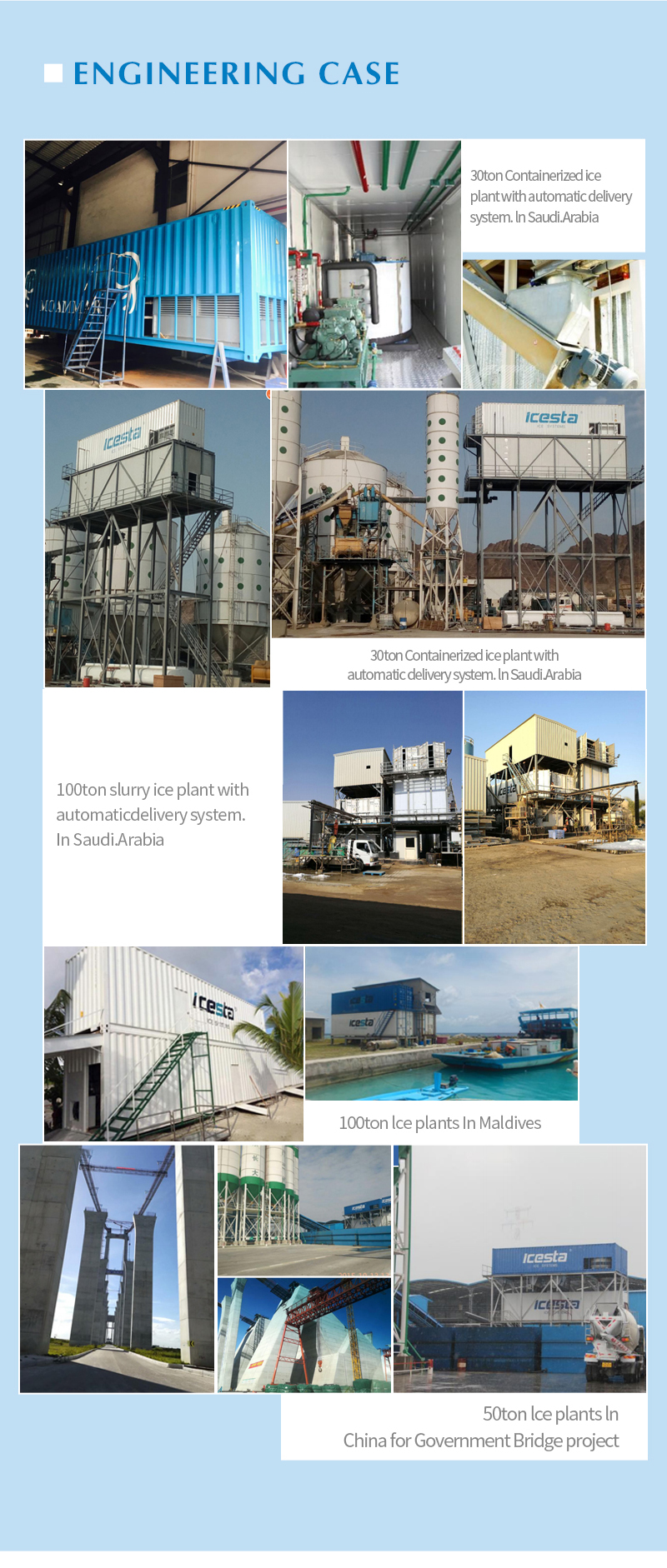

About ICESTA

20 years dedication in ice making technology to create excellence.

Shenzhen Brother Ice System Co., Ltd. ( ICESTA Brand), a well-known ice machine manufacturer and industry leader and pioneer in China.The product covers flake ice /Block ice machine, Tube ice /slurry ice/plate ice/cube ice machines, water

chillers,Plate/spiral/blast freezers, Automatic ice storing & delivery system with integrated container ice system,artificial snow making machine.etc

Experiences & History:

20-Years Team focus on innovative solution in Ice & Cooling technology.

17-Years Professional Manufacturer, Supplier of Excellent Turnkey ice & cooling projects.

Industry status& Reputation:

* TOP 3 of China industrial ice machine Brand with strong capability of R&D

* 20000㎡ Factory

* ISO 9001 , CE, PED, ASME (U.S ) Certificates etc

Technology & Management capability:

* 80+ patents Certificates

* High Technology enterprise Certificate

Services & Global Net:

* Export to 80+ countries

* Local service in 50+ countries with networks all over the world.

* 1-2 years warranty covers each component.

Four Major Brands

Quick Links

Contact Us

+86 755 2991 4211 - 803 (Tel.)

+86 755 29914210 (Fax)

+86 17665486066 (Cel)

Whatsapp: +86 17665486066

Wechat: +86 17665486066

EMAIL: laurene.luo@icesta.com

SKYPE: icesta-laurene